Fabricated wallboard corner structure

A prefabricated and corner technology, which is applied in building construction, covering/lining, construction, etc., can solve the problems of inability to mass-manufacture and use, and the complex corner structure of prefabricated wall panels, so as to reduce design and production costs and improve versatility , high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

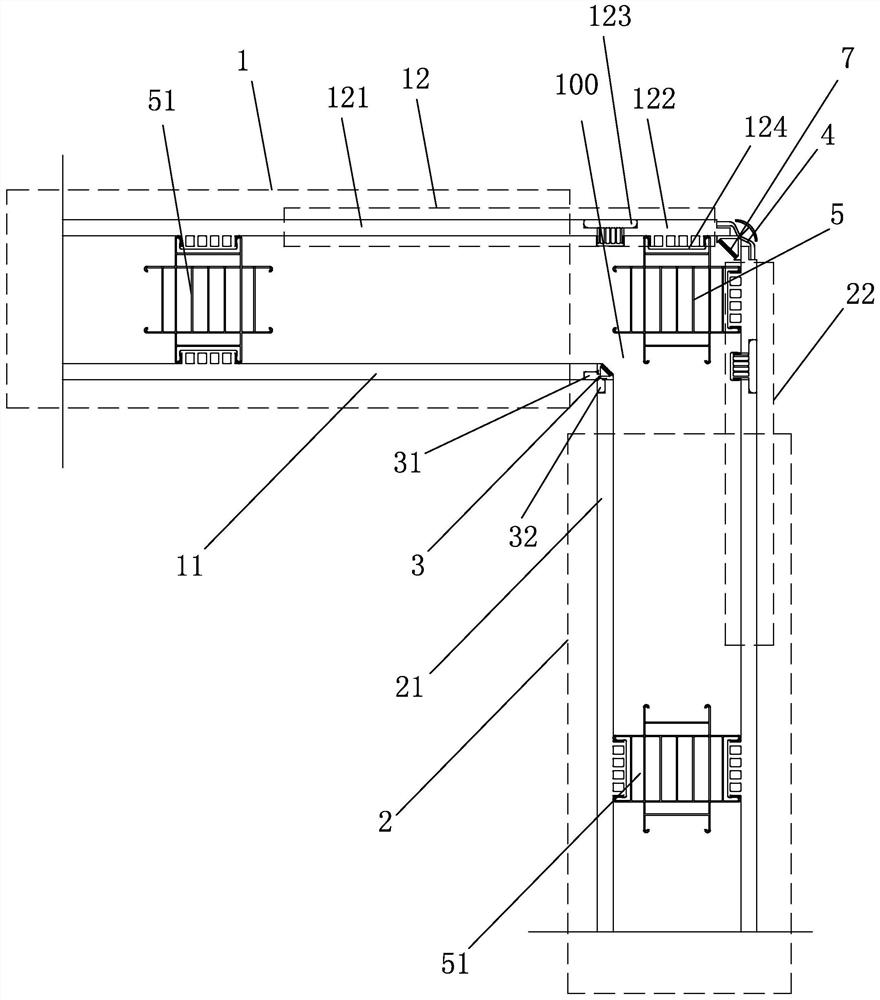

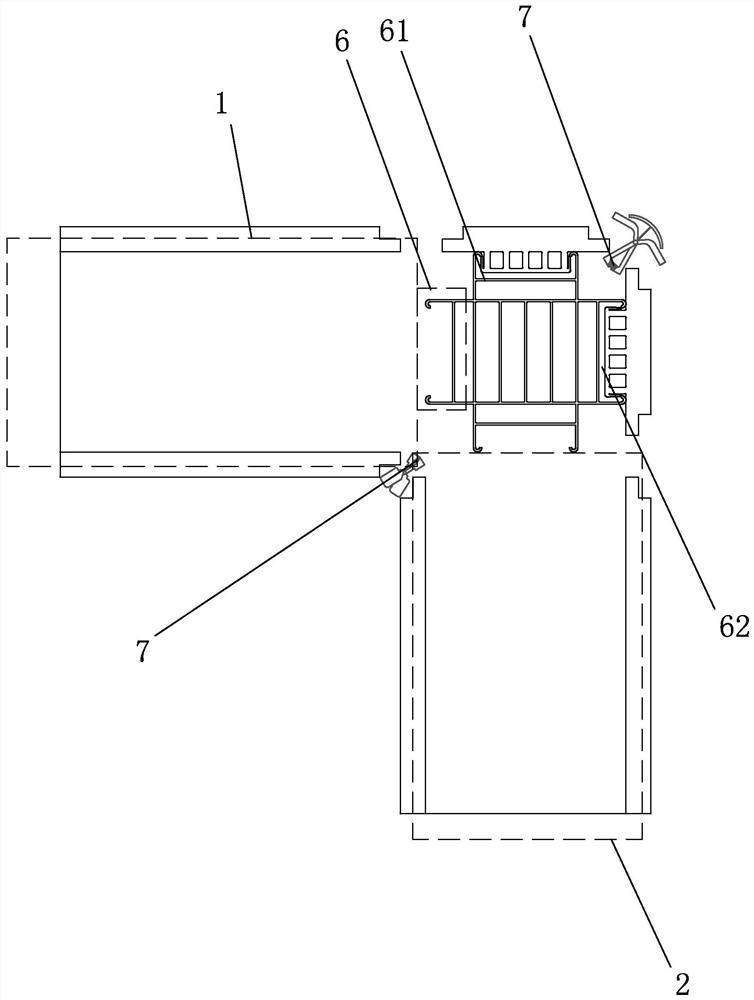

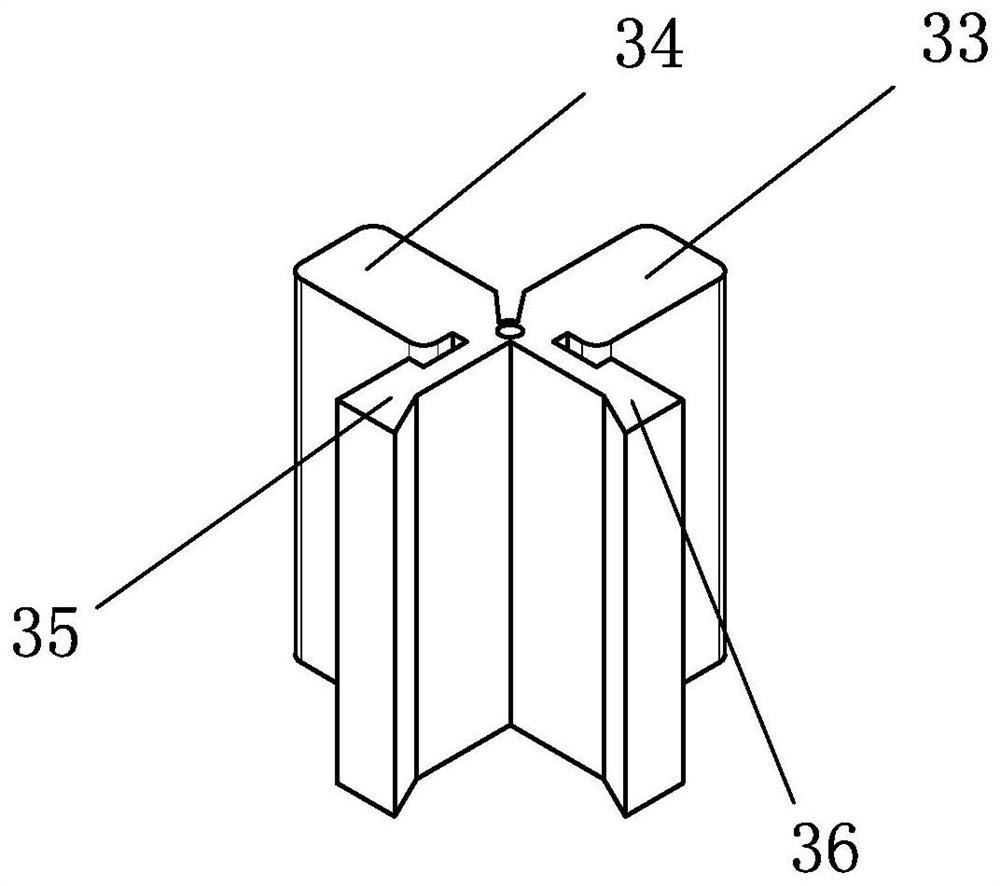

[0027] like figure 1 As shown, a prefabricated wall panel corner structure includes a first connection part 1 and a second connection part 2 that are combined to form a wall panel corner 100, and a scissor type is arranged between the first connection part 1 and the second connection part. The elastic buckle assembly, the scissor-type elastic buckle assembly includes a female corner buckle 3 arranged on the inside of the wallboard corner 100 and a male corner buckle 4 arranged on the outside of the wallboard corner 100, the female corner buckle A corner fastening part 5 for an included angle is provided between the male corner buckle part and the corner fastening part, and the corner fastening part is used to fasten the first connecting part 1 and the second connecting part. like image 3 As shown, the female corner buckle includes a hinged left buckle 31 and a right buckle 32, and the middle parts of the left buckle and the right buckle are all provided with hinge points, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com