Municipal road sewer pipeline construction equipment and method

A technology for pipeline construction and municipal roads, which is applied in the sewer system, waterway system, water supply device, etc., can solve the problems of inconvenience and manual operation steps, and achieve the effects of improving safety, saving manpower, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

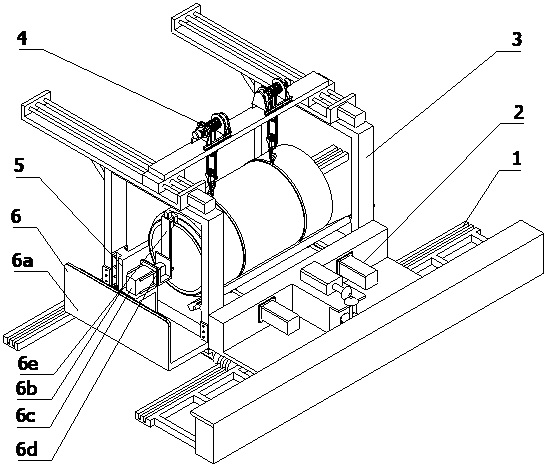

[0047] In order to achieve the purpose of automatically applying non-corrosive lubricant to the rubber ring at the socket when placing the rebated pipe into the groove, to solve the technical problem that the rebated pipe can be installed directly after entering the groove, such as figure 1 as shown,

[0048] A municipal road sewer pipeline construction equipment and method, comprising:

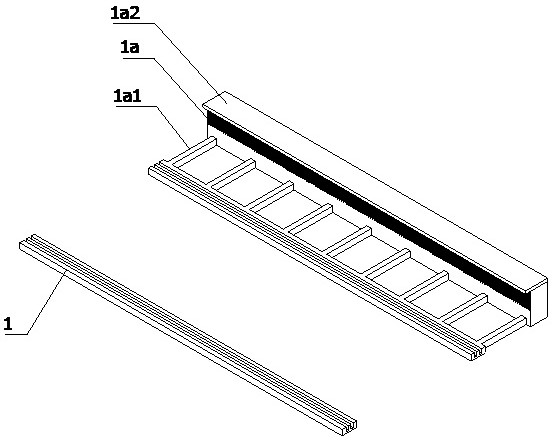

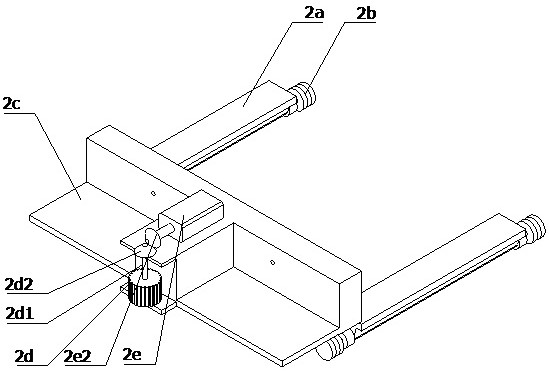

[0049] The moving track 1, the moving track 1 is laid on both sides of the groove, the driving assembly 2 for moving on the moving track 1 is installed on the moving track 1, the mounting frame 3 is arranged above the driving assembly 2, and the mounting frame 3 is arranged There is a pipeline moving mechanism 4 for movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com