Ship anti-impact protection structure based on aluminum honeycomb optimization

A protective structure, aluminum honeycomb technology, applied in the direction of anti-collision, hull, hull parts, etc., can solve the impact environment of the ship, the damage of the overall structure of the breach, the threat of the ship's outer plate structure shipboard equipment and shipboard personnel, etc. , to achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

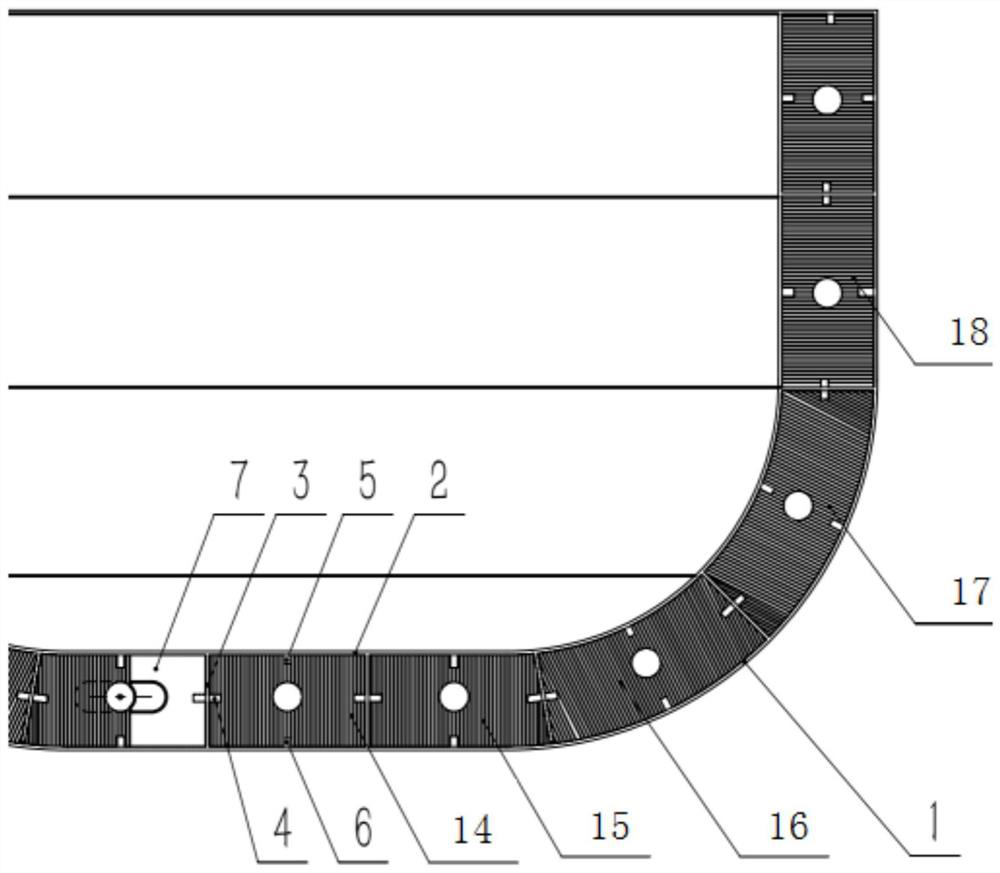

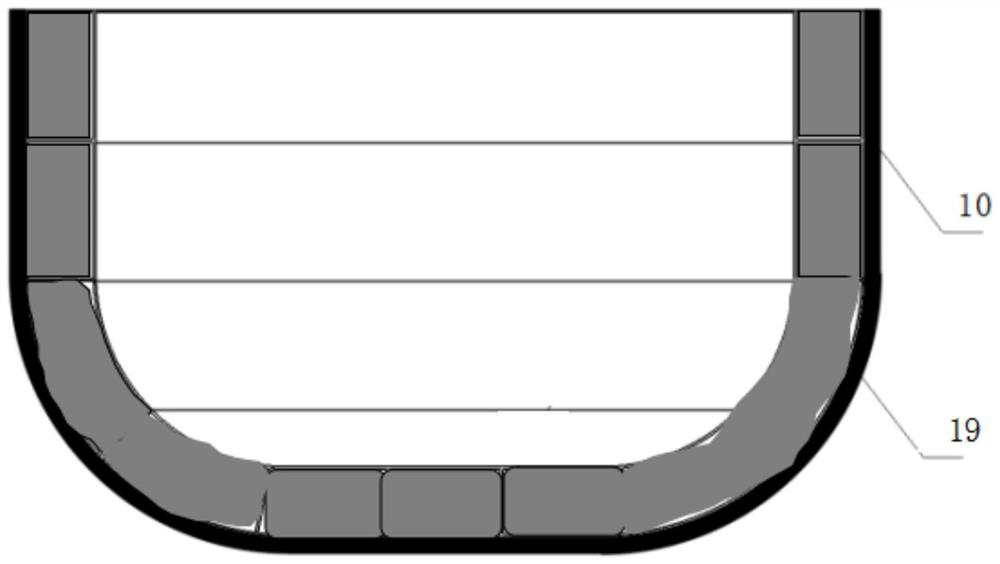

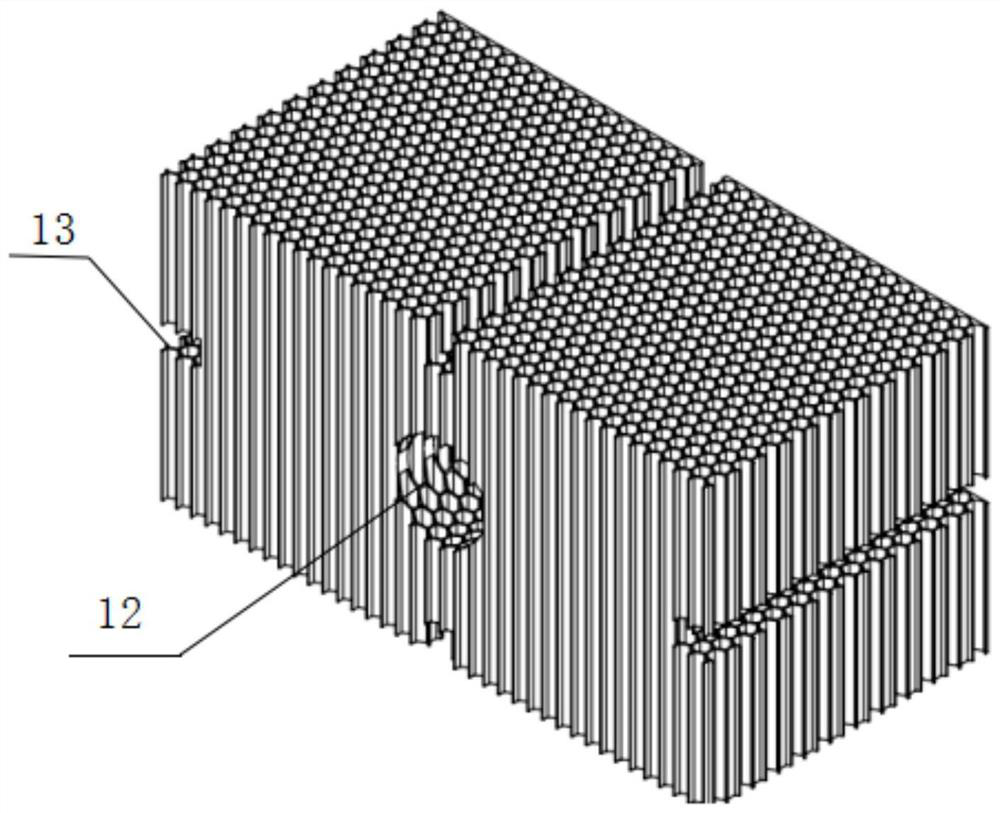

[0032] Such as Figure 1-Figure 6 As shown, a ship anti-shock protection structure based on aluminum honeycomb optimization, including hull outer plate 1, hull inner plate 2, hull girder 3, hull solid floor plate 7 and inner protective structure, said hull outer plate 1 , hull inner plate 2, hull girder 3 and hull solid floor 7 encircle a plurality of small cabins, and the described inner protection structure is filled in a plurality of small cabins;

[0033] A number of hull longitudinal stiffeners 6 are evenly arranged on the outer hull plate 1, a number of hull longitudinal stiffeners 5 are uniformly arranged on the hull inner plating 2, and hull girder reinforcements are arranged on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com