Reinforced striking system

The technology of a cover and a rotating rod is applied in the field of beating systems, which can solve the problems of inability to improve the performance of finished medicines, affect batch manufacturing, poor manufacturing performance, etc., and achieve the effects of improving the properties of finished medicines, good ingredient performance and strong compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

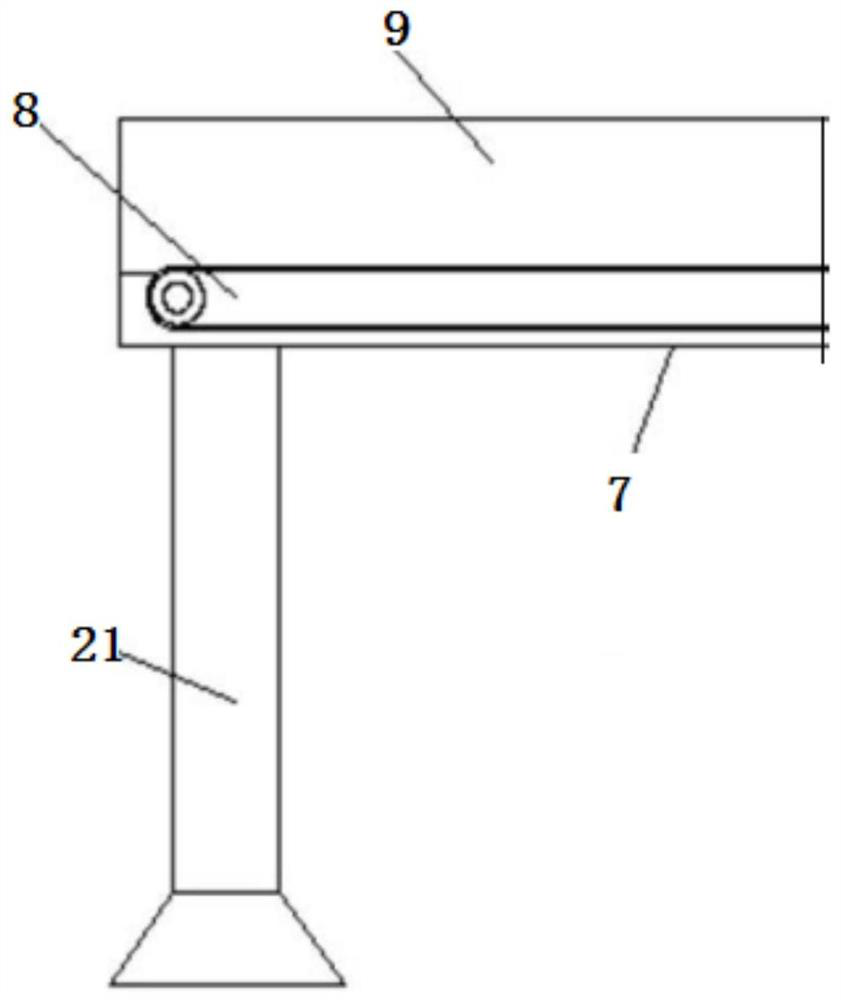

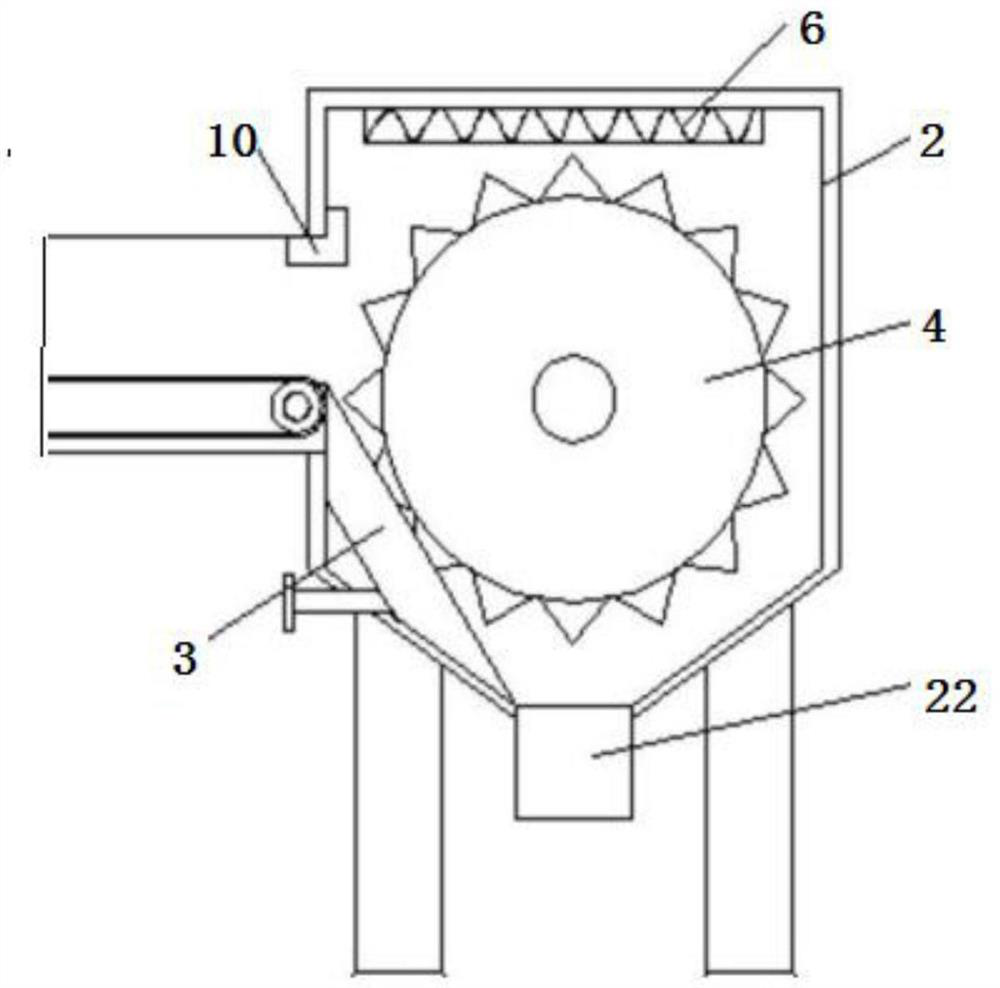

[0020] During the application period, it is required to transfer the pharmaceutical ingredients or intermediate product ingredients to the gold beating system to perform the beating business. However, the current beating system is manually used to feed the ingredients, which is time-consuming and labor-intensive, and has poor manufacturing performance. In addition, when beating, the ingredients are too rigid If it is large, the knocking performance is also poor, and the performance of the finished drug cannot be improved, which affects its large-scale application in batch manufacturing. improved, such as Figure 1-Figure 2 As shown, the reinforced beating system includes a beating cover 2, the inner side of the beating cover 2 is fixedly assembled with a beating rod 4 via a slewing bearing, and the front wall of the beating cover 2 is fixedly fitted with a speed control motor 5.

[0021] In addition, the rotating rod of the speed regulating motor 5 protrudes through the beati...

Embodiment 2

[0028] like Figure 1-Figure 2 As shown, the reinforced beating system includes a beating cover 2, the inner side of the beating cover 2 is fixedly assembled with a beating rod 4 via a slewing bearing, and the front wall of the beating cover 2 is fixedly fitted with a speed control motor 5.

[0029] In addition, the rotating rod of the speed regulating motor 5 protrudes through the beating cover 2 and is firmly connected to the beating rotating rod 4 , and one side of the beating cover 2 is opened and welded to the support table 7 .

[0030] In addition, the upper part of the support table 7 is embedded with a chain plate transmission body 8 , the upper outer wall of the support table 7 is hooped with the blocking shell 9 , and the lower part of the inner side of the beating cover 2 is fixedly assembled with a protruding block 3 . .

[0031] The protruding teeth on the wall surface of the rotating rod 4 for beating protrude into the opening of the wall surface of the protrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com