Load-bearing frame based on non-profile structure, main stand columns and layer plates

A technology for load-bearing racks and main columns, applied to structural parts, electrical components, battery pack parts, etc., can solve the problem that the rack does not have overall size flexibility, the air duct cannot be adjusted in a targeted manner, and the product delivery period is long and other issues, to achieve the effect of shortening the delivery period, easy adjustment and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical problems solved by the present invention, the technical solutions adopted and the technical effects achieved clearer, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0034] Refer below Figure 1-Figure 10 The specific structure of the load-bearing frame based on the non-profile structure according to the embodiment of the present invention is described.

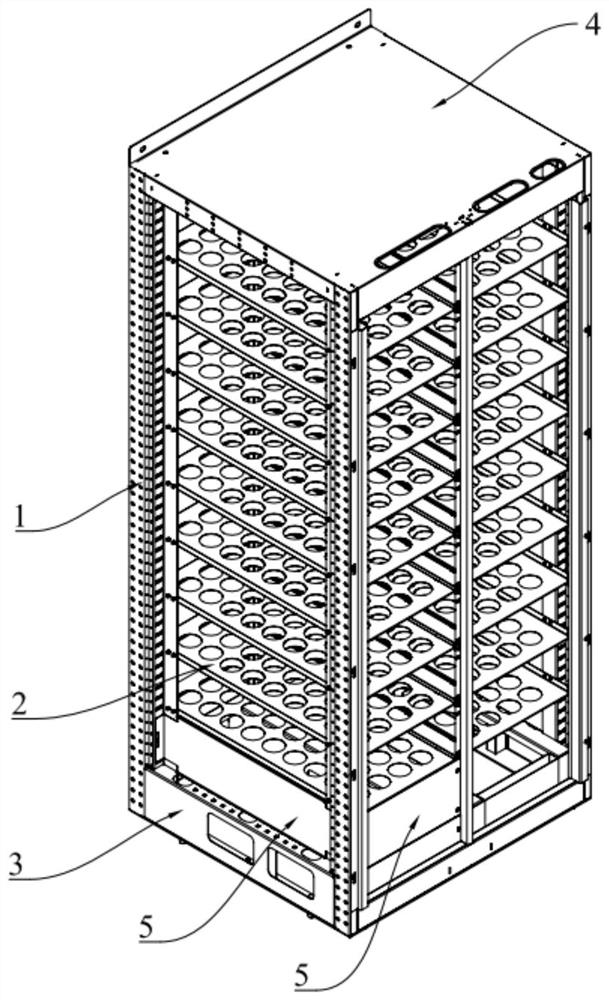

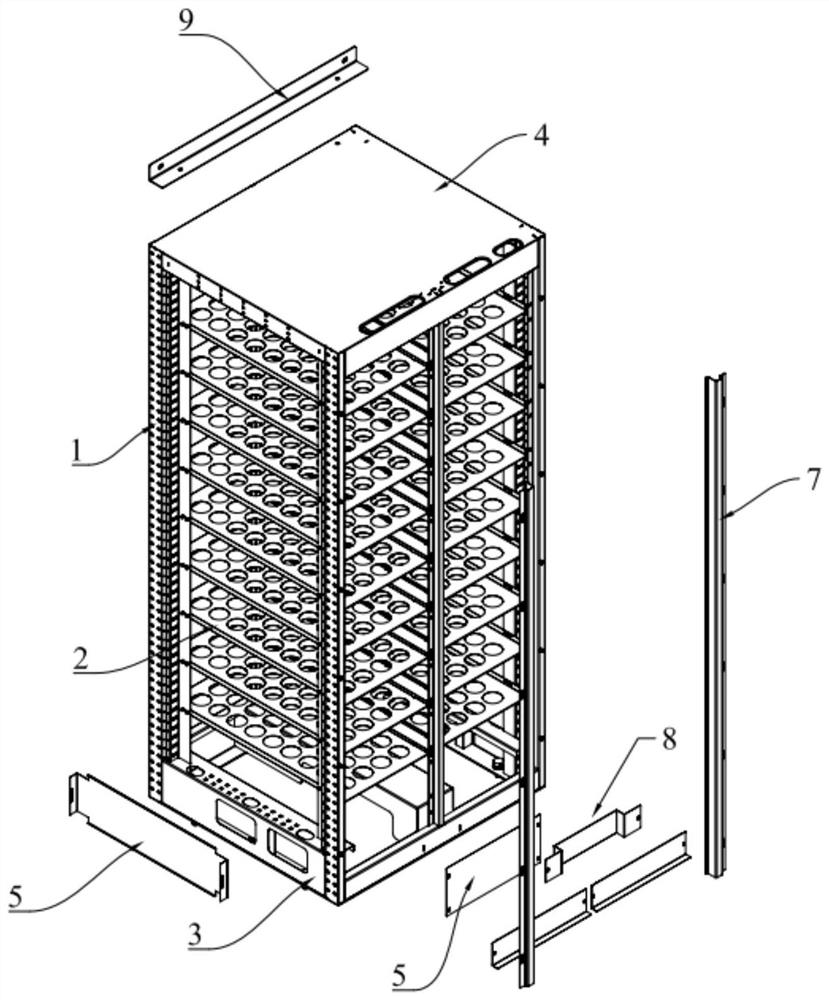

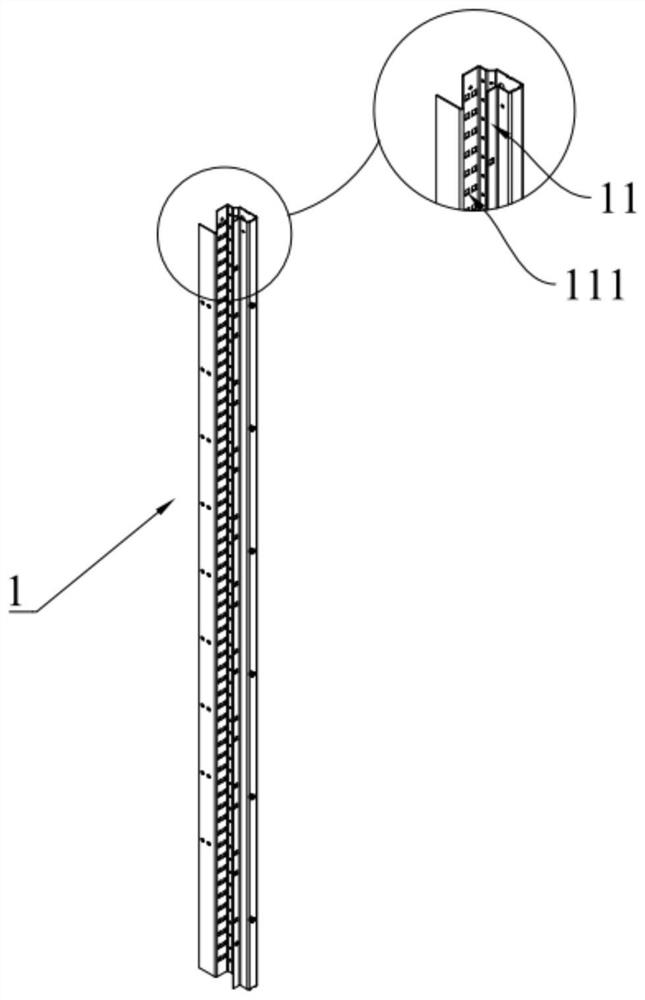

[0035] Such as Figure 1 to Figure 3 As shown, the present embodiment provides a load-bearing frame based on a non-profile structure, including a main column 1, a laminate 2, a base, a top plate 4, and a wind panel 5. There are multiple main columns 1, and multiple main columns 1 along the The vertical direction is arranged in parallel at intervals, the main column 1 is a multi-folded 11 structure, and there are multiple laminates 2, and the plurality of laminates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com