Etching machine structure capable of dynamically adjusting horizontal position of coil

A technology of horizontal position and dynamic adjustment, which is applied in the direction of discharge tubes, electrical components, circuits, etc., and can solve problems such as affecting yield, distortion of process parameters, and inability to effectively clean the reaction chamber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

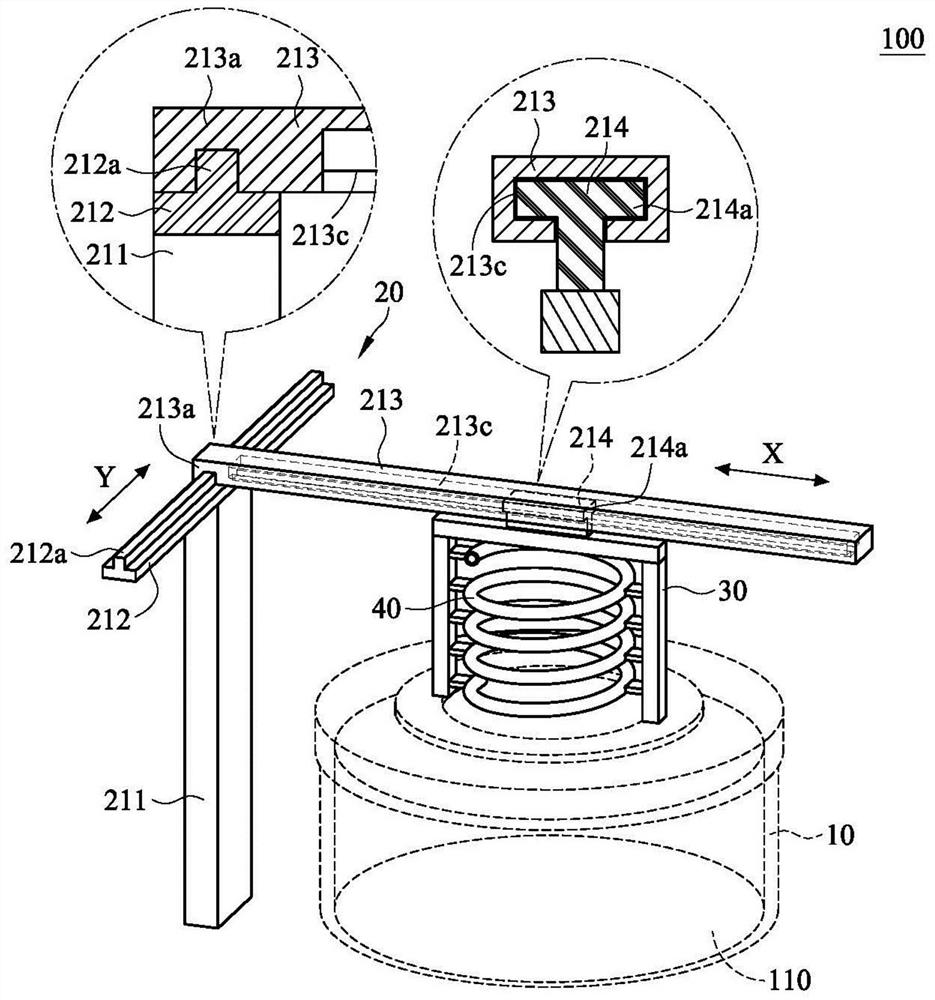

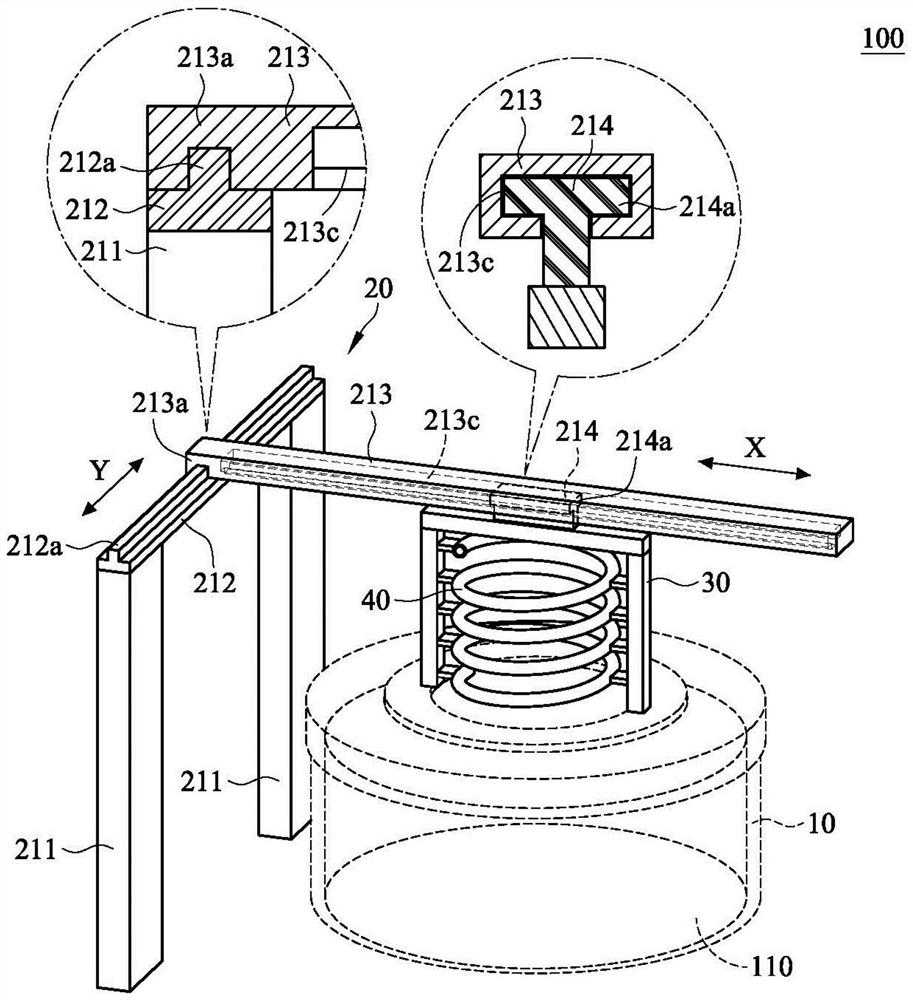

[0046] like figure 2 and image 3 As shown, this embodiment is an etching machine structure 100 with dynamically adjustable coil horizontal position, which includes: a first plasma reaction chamber 10 ; a horizontal sliding module 20 ; a coil support 30 ; and a coil module 40 .

[0047] The first plasma reaction chamber 10 is, for example, a plasma reaction chamber capable of completing semiconductor or photoelectric device etching process, and the first plasma reaction chamber 10 has a first reaction chamber 110 .

[0048] The horizontal slide module 20 has: at least one first height support 211 ; a first horizontal support 212 ; a first slide 213 ; and a second slide 214 .

[0049] The first height support 211 is fixed on the first side of the first plasma reaction chamber 10, and the first height support 211 supports the coil module 40 and makes the coil module 40 span the first plasma reaction chamber 10 The height is so that the coil module 40 will not interfere with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com