Butterfly valve with high tightness and using method thereof

A tightness, butterfly valve technology, applied in the direction of lift valve, valve device, engine components, etc., can solve the problems affecting tightness, affecting the quality of valve closing, overflow, etc., and achieve the effect of avoiding fluid overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

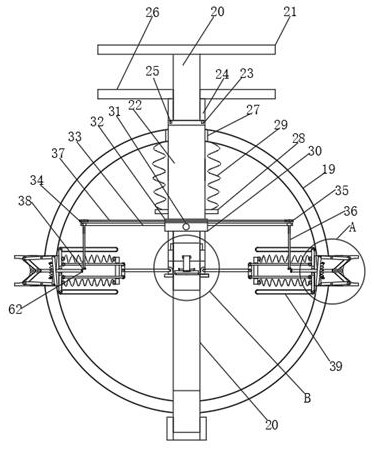

[0026] Such as Figure 1-5 As shown, the present invention provides a butterfly valve with high tightness, which is characterized in that it includes: a valve body 1 and a pipe body 2 communicating with the valve body 1, the bottom of the inner wall of the valve body 1 is fixedly connected with a rotary sleeve, and the rotary sleeve A rotating rod 20 is sleeved inside, and the rotating rod 20 is set with a valve 19. The valve 19 is sleeved in the valve body 1. The top of the rotating rod 20 runs through the top of the inner wall of the valve body 1 and extends above it. The top of the rotating rod 20 There is a turntable 21 fixedly connected, a sliding sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com