Drum brake

A technology of drum brakes and brake drums, which is applied in the direction of mechanically driven drum brakes, brake types, brake components, etc., which can solve the problems of easy falling off of screws, large heat generation, poor heat dissipation, etc., and achieve heat dissipation Fast, prevent overheating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

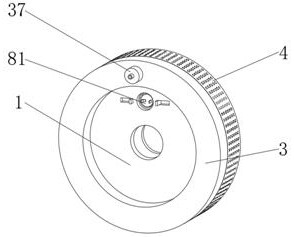

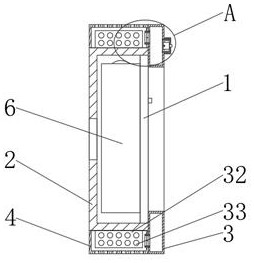

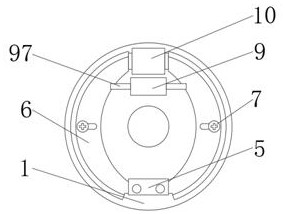

[0025] A drum brake, comprising a bottom plate 1, a brake drum 2, a water tank 3, a protective cover 4, a hinged frame 5, a brake shoe 6, a limit screw 7, an inner ring gear 8, an adjustment cylinder 9 and a short shaft 95, the The outer side of the bottom plate 1 is rotatably connected with a brake drum 2, the outer side of the bottom plate 1 is fixedly connected with a water tank 3, the water tank 3 is in contact with the brake drum 2, and the water tank 3 is fixedly connected with a protective cover 4. The protective cover 4 is rotatably connected with the brake drum 2, the outer side of the bottom plate 1 is fixedly connected with a hinged frame 5, and the inner side of the hinged frame 5 is hinged with two symmetrically distributed brake shoes 6, the brake shoes 6 and A torsion spring is connected between the hinged frames 5, and a driver 10 is fixedly connected to the outside of the bottom plate 1, and the driver 10 is in contact with the brake shoe 6, and the brake shoe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com