A prefabricated prefabricated house for a construction site

A prefabricated house and construction site technology, applied in construction, building components, residential construction, etc., can solve problems such as large manpower consumption, house water seepage, and roof collapse, so as to reduce labor intensity, low cost, and guarantee The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

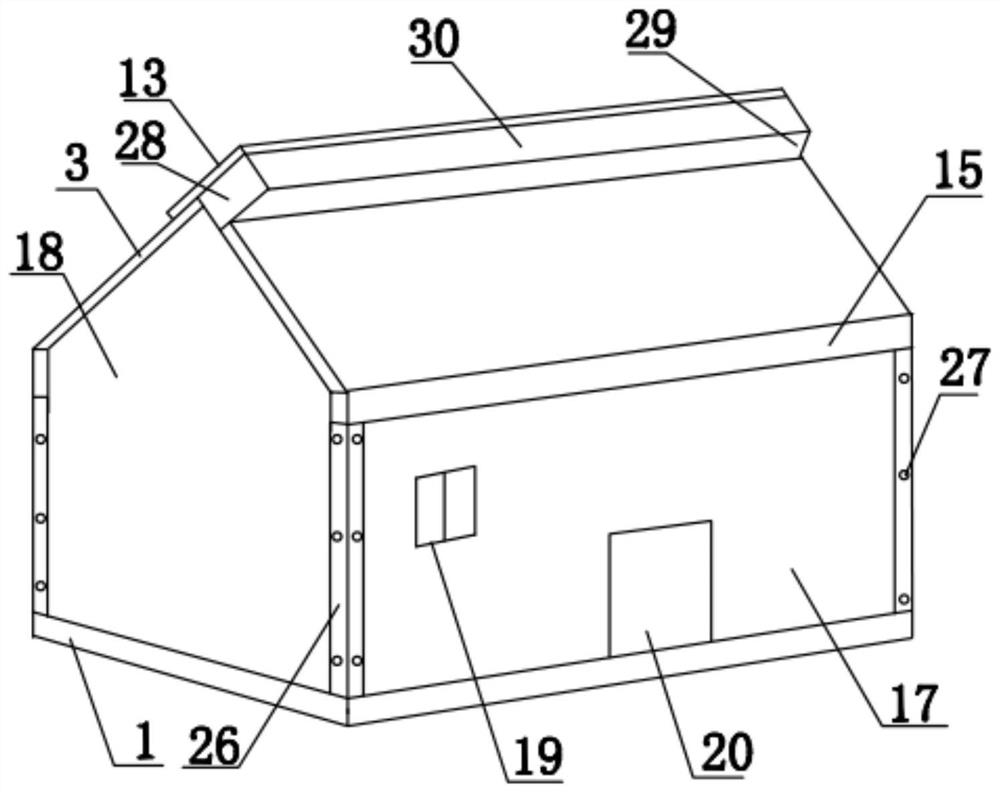

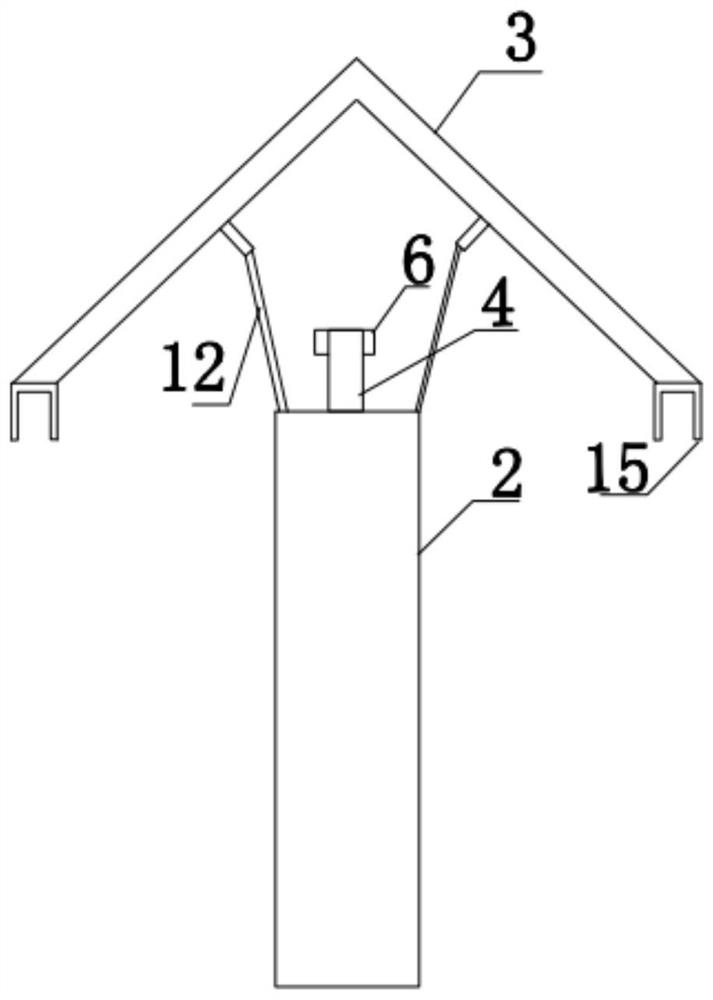

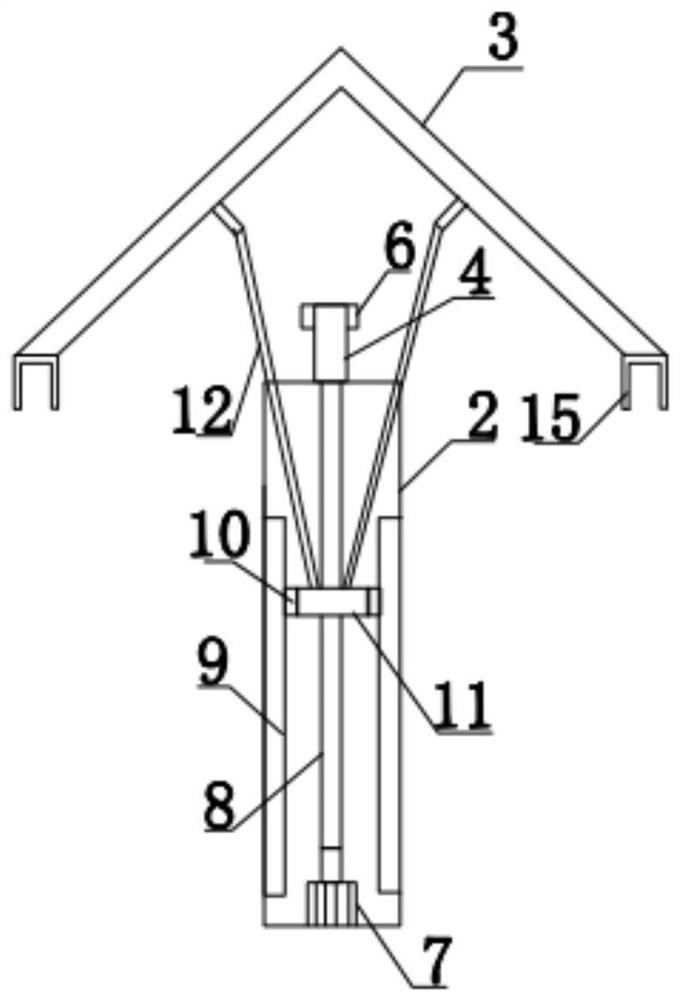

[0026] An assembled prefab house for a construction site, comprising a bottom plate 1, and a square cavity 2 is arranged at the center of the bottom plate 1. In order to improve the convenience of turnover transportation, a fixed cavity that is inserted into the square cavity can be set at the center of the bottom plate. , During the turnover transportation, the two can be separated for easy transportation. Above the square cavity 2, there is a roof composed of two hinged plates 3. The two plates can be connected by hinges. A driving mechanism for driving the two plate bodies 3 to extend or contract, the driving mechanism includes two vertical plates 4 correspondingly arranged on the top of the square cavity 2, and a horizontal plate 5 arranged between the two vertical plates 4 for connecting the two , a first bearing 6 is arranged on the horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com