Use method of toilet cleaner for water-tank-free toilet

A technology of toilet cleaning liquid and no water tank, applied in the field of bathroom, can solve problems such as inability to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

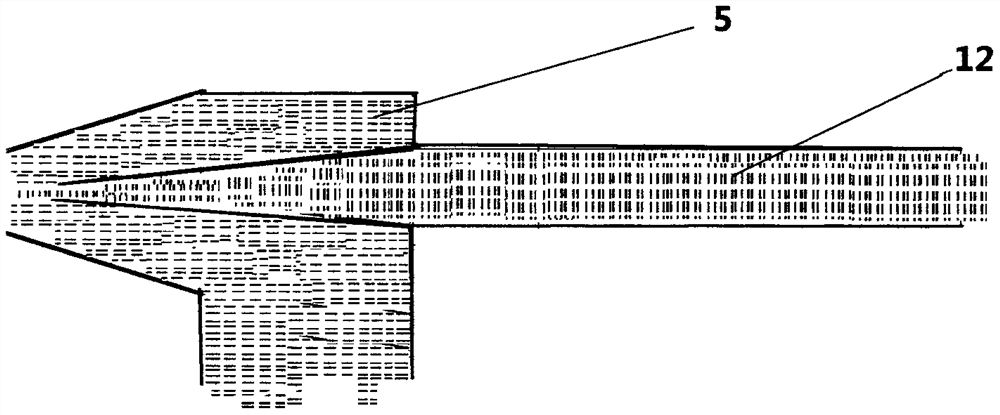

Embodiment 1

[0022] Depend on image 3 Shown: in the second section of the toilet flushing, the down flushing solenoid valve 15 is opened, and the down flushing water pipe 16 flushes to the sewer with the dirt on the bottom of the toilet sinking in the water 7, and the tap water in the down flushing water pipe 16 passes through the three-way The replenishing water pipe 14, replenishes water in the liquid toilet liquid bottle 19 by the flow regulating valve 11, dilutes and concentrates the liquid cleansing the toilet liquid 17, regulates the flow regulating valve 11 on the water replenishing pipe 14 and can control the amount of water replenishment, so that the liquid toilet liquid 20 after dilution The toilet liquid level 8 rises to the required height; after the second stage of flushing, close the downflush solenoid valve 15, and open the upflush solenoid valve 18 in the third stage. Under the action of the water flow with a large flow rate at the outlet of the upper flushing water pipe 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com