Simple and convenient brake disc manufacturing and forming device

A molding device and brake disc technology, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, can solve the problems of potential safety hazards, time-consuming and labor-intensive problems, and achieve the effect of shortening the contact distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

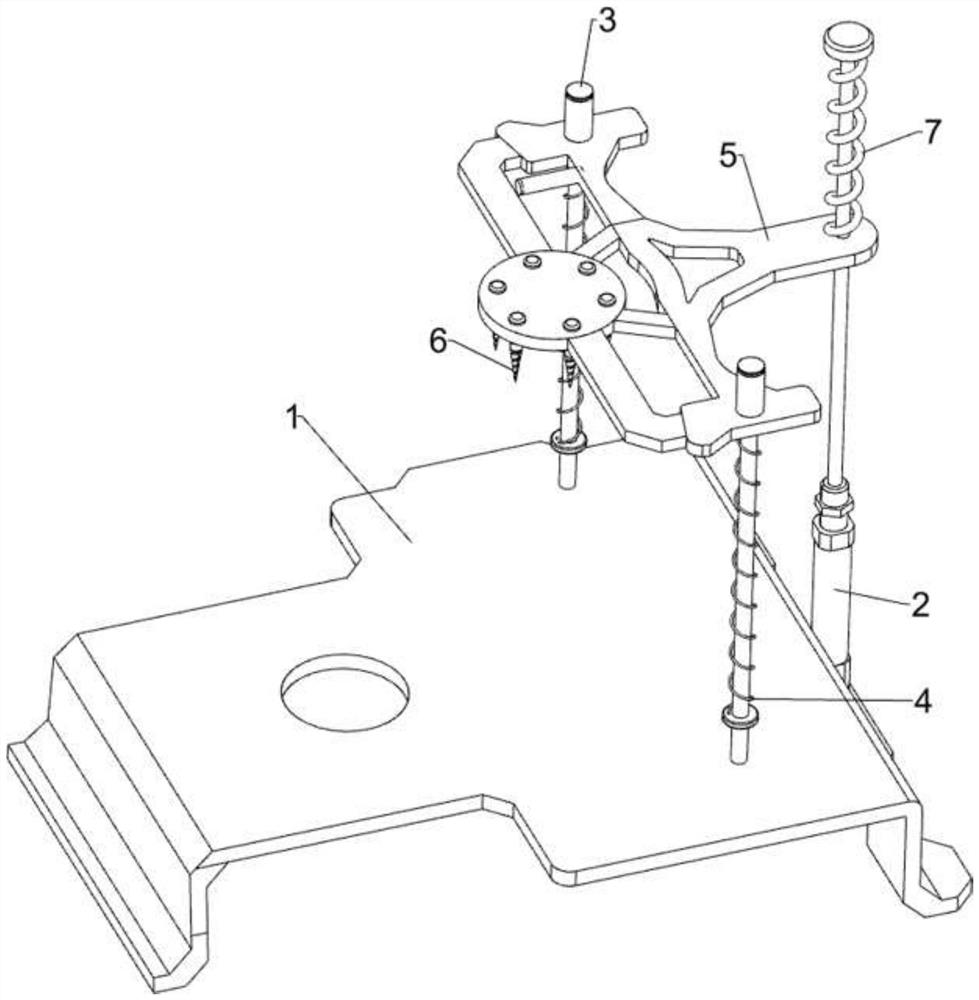

[0045] A simple brake disc manufacturing molding device, such as figure 1 and figure 2 As shown, it includes a bottom plate 1, a cylinder 2, a first fixed rod 3, a first spring 4, a pressure plate 5, a drilling machine 6, a second spring 7, a pushing mechanism 8 and a feeding mechanism 9, and the top right side of the bottom plate 1 A cylinder 2 is provided, first fixed rods 3 are provided on the front and rear sides of the top of the bottom plate 1, and a pressing plate 5 is slidably arranged between the first fixed rods 3, and the pressing plate 5 is slidably connected to the telescopic rod of the cylinder 2 and is connected to its top. The second spring 7 is connected, the first spring 4 is connected between the bottom of the pressing plate 5 and the first fixed rod 3, the drilling machine 6 is arranged on the left side of the pressing plate 5, and the pushing mechanism 8 is arranged on the top of the bottom plate 1, and the pushing mechanism 8 The left part is connected ...

Embodiment 2

[0048] On the basis of Example 1, such as image 3 and Figure 4 As shown, the pushing mechanism 8 includes a first pressing bar 81, a wheel bar 82, a material pushing frame 83, a rope 84, a third spring 85 and a push plate 86, and the right side of the bottom plate 1 is symmetrically provided with a wheel bar 82, and the wheel bar 82 tops are provided with wheels, and the telescopic end of cylinder 2 is connected with the first depression bar 81, and base plate 1 top is provided with pusher frame 83, and push plate 86 is provided with sliding type on the pusher frame 83, and the right side of push plate 86 all walks around Two ropes 84 are connected between the wheel and the first depression bar 81 , and two third springs 85 are connected between the right side of the push plate 86 and the push frame 83 .

[0049] The blanking mechanism 9 includes a first fixed block 91, a blanking frame 92, a push block 93, a baffle plate 94 and a fourth spring 95, and the front and rear si...

Embodiment 3

[0052] On the basis of Example 2, such as Figure 5 to Figure 8 As shown, a clamping mechanism 10 is also included. The clamping mechanism 10 includes a guide rod 101, an inclined block 102, a fifth spring 103, a lifting frame 104, a sixth spring 105 and a clamping disc 106. The top of the bottom plate 1 is provided with 3 A guide bar 101, between the guide bars 101 is slidingly provided with an inclined block 102, the fifth spring 103 is connected between the inclined block 102 and the right part of the guide bar 101, the top of the base plate 1 is symmetrically provided with a lifting frame 104, the lifting frame 104 The telescopic end sleeve is provided with a sixth spring 105, and a clamping disc 106 is connected between the tops of the elevating frame 104, and the clamping disc 106 is slidably connected with the right part of the pushing frame 83.

[0053] The telescopic rod of cylinder 2 shortens and extrudes the inclined block 102 to move to the left under the guidance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com