A wireless control system for deep penetration arc welding machine

A wireless control and arc welding machine technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as difficult linkage operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

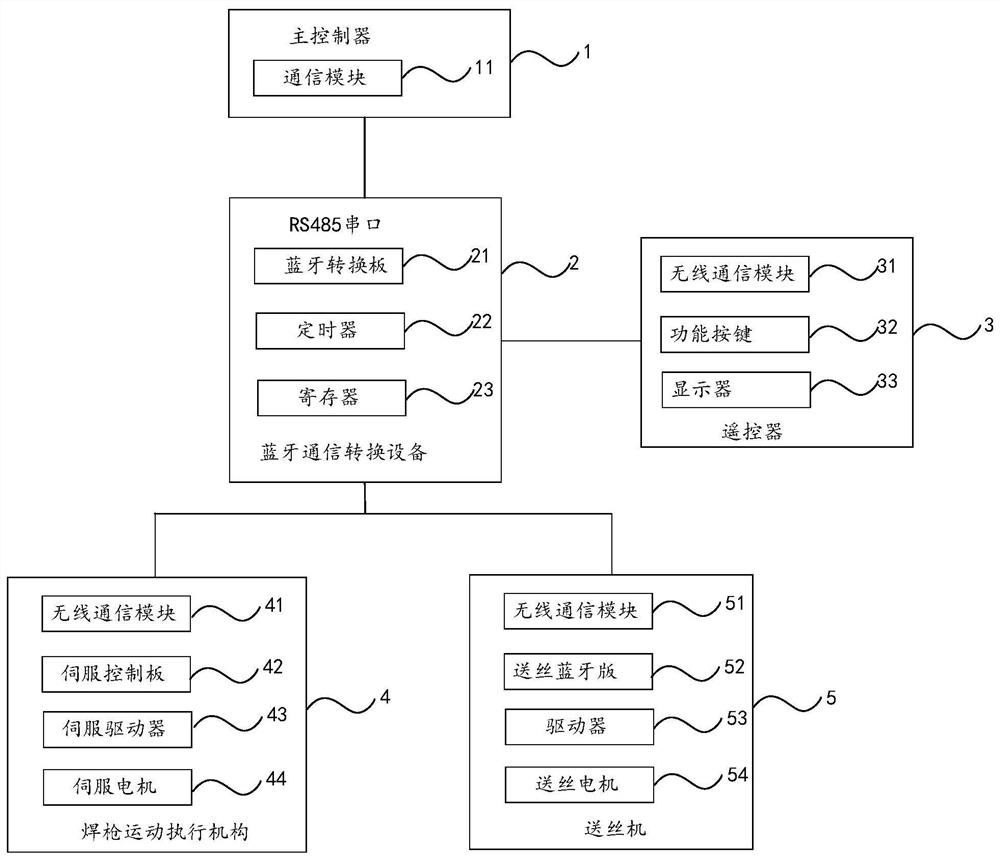

[0059] See figure 1 , shows a structural block diagram of a deep penetration arc welding machine wireless control system, the system includes: a main controller 1, a wireless communication conversion device 2, a remote control 3 and the required The operating equipment includes a welding torch motion actuator 4 and a wire feeder 5; the main controller is provided with a communication module 11, and the remote controller 3, welding torch motion actuator 4 and wire feeder 5 are all A wireless communication module 31 / 41 / 51 is provided; the wireless communication conversion device is connected to the communication module 11 and the wireless communication module 31 / 41 / 51 respectively, and is used to execute the movement of the remote control 3 and the welding torch. The data reported by the mechanism 4 and the wire feeder 5 are processed, and are also used to distribute the control commands sent by the main controller 1 to the remote controller 3 , the welding torch motion actuator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com