Shipment sorting system

A sorting system and sorting table technology, applied in sorting and other directions, can solve the problems of reduced cost and efficiency, low efficiency of pure manual express sorting, unrealistic, etc., to achieve error rate control, compact structure, and space saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

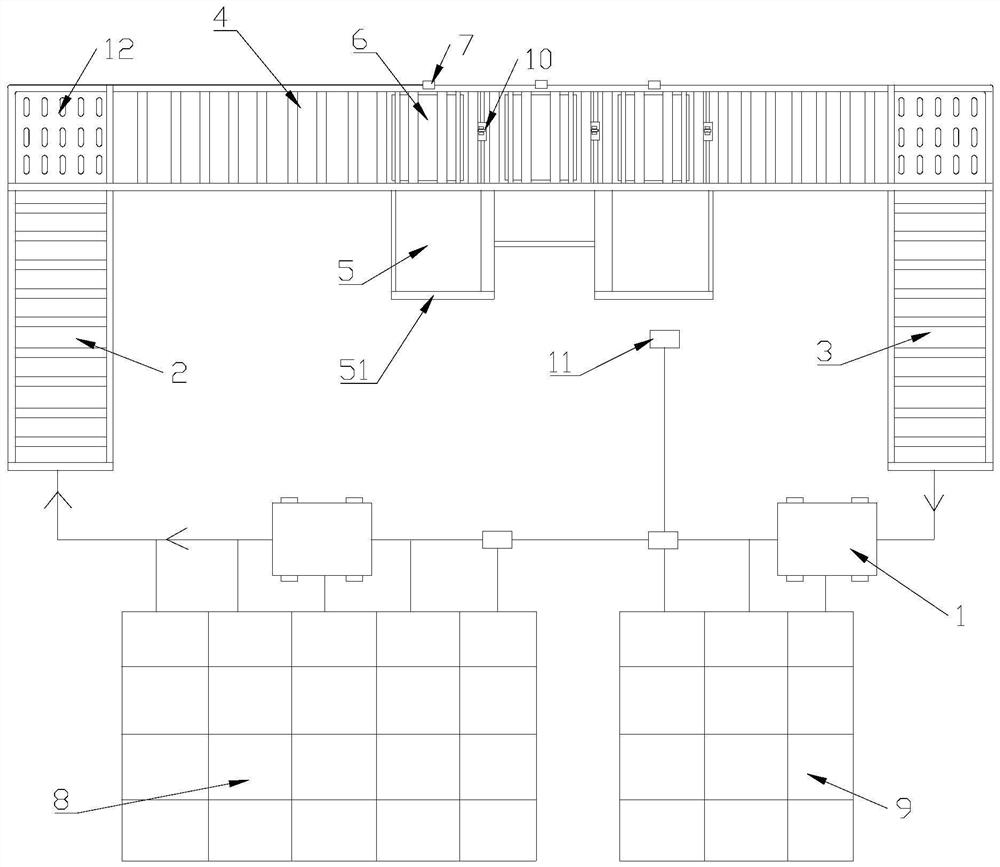

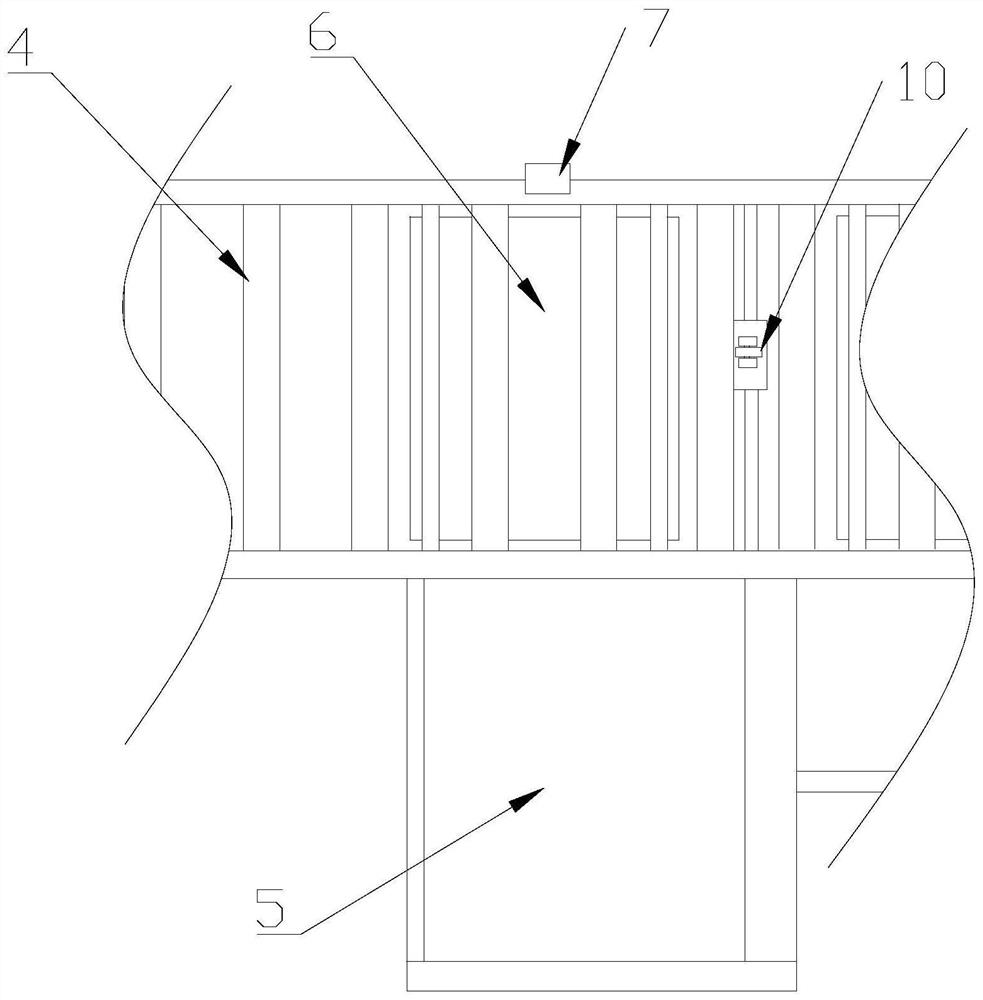

[0017] See attached Figure 1-2 As shown, a delivery sorting system of the present invention includes a cargo storage rack, a picking and conveying mechanism, and a transport trolley for transporting the cargo back and forth between the cargo storage rack and the picking mechanism. The picking conveying mechanism is located on one side of the cargo storage rack, and the picking conveying mechanism includes mutually parallel feeding conveying lines, unloading conveying lines and a picking conveying line between them, and the feeding conveying lines and unloading conveying lines Parallel to each other, the picking conveying line and the feeding conveying line are vertically arranged and located on the side away from the goods storage rack. The feeding conveying line, the unloading conveying line and the sorting conveying line are roller conveying lines, and the connection between the sorting conveying line and the feeding conveying line and the unloading conveying line is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com