Industrial spraying robot

A spraying robot and industrial technology, which is applied in the direction of manipulators, spraying devices, manufacturing tools, etc., can solve the problems of reduced spraying efficiency, sticking nozzles, uneven spraying paint, etc., to achieve accurate and uniform spraying positions and increase spraying volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to achieve the technical means of the present invention, the creation characteristics, the achievement of the purpose and the function is readily understood, and the specific embodiments are combined.

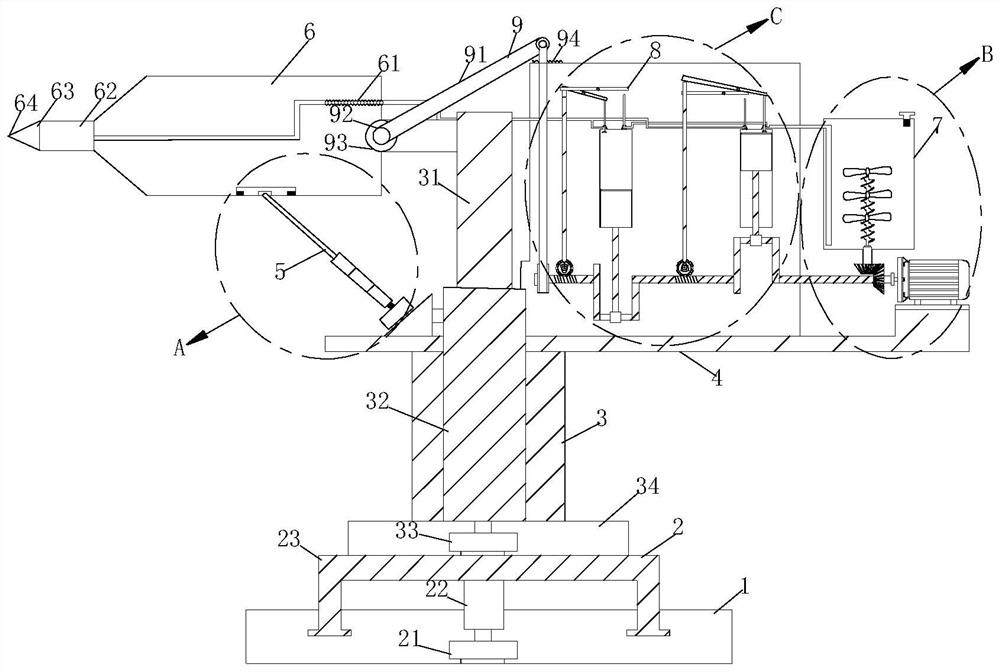

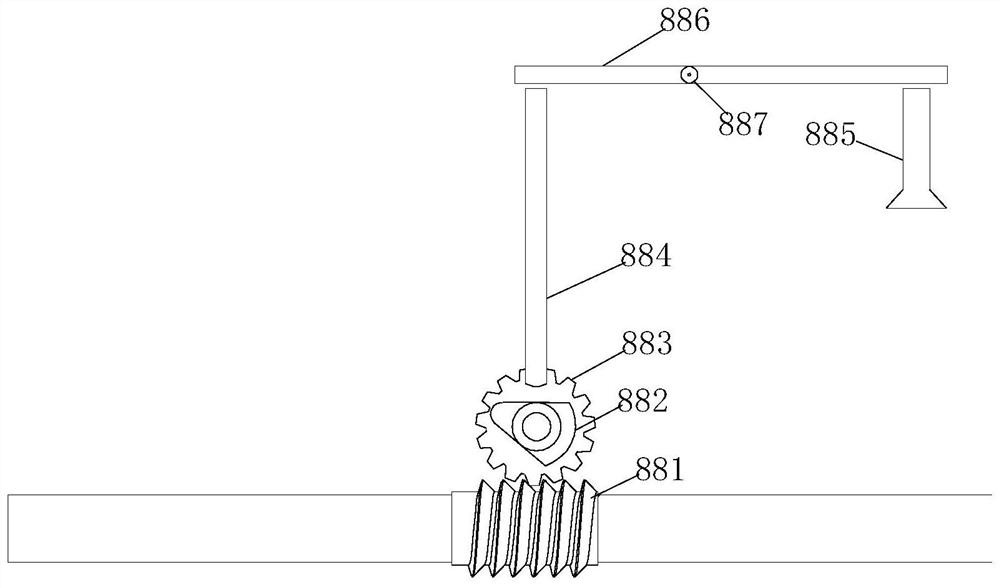

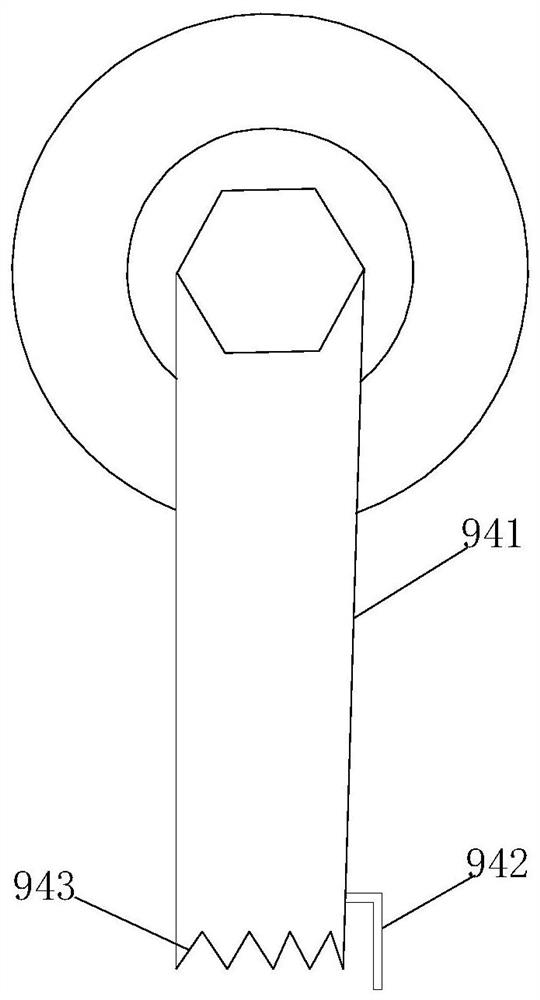

[0026] Such as Figure 1 - Figure 7 As shown, a industrial spray robot of the present invention includes a base 1, a rotating mechanism 2 is provided on the base 1, and the elongation mechanism 3 is located above the rotating mechanism 2, and the elongated mechanism 3 is fixed, respectively, respectively. The support frame 4 is fixed above the left end of the support frame 4, and the support frame 4 is respectively provided with the right end of the support frame 4, and the storage mechanism 7 and the pressurizing mechanism 8 are passed through a feed tube. 71 Connection, the hydraulic limit mechanism 5 slides over the upper side of the spray gun 6, and the spray gun 6 is connected to the right side. The operator can install the spray robot in a suitable position, ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com