An agricultural cotton dehulling machine

A shelling machine and cotton technology, applied in agricultural machinery, shelling, application, etc., can solve the problems of increased cotton volume, low production cost, and difficult discharge, so as to improve the crushing capacity and ensure normal work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

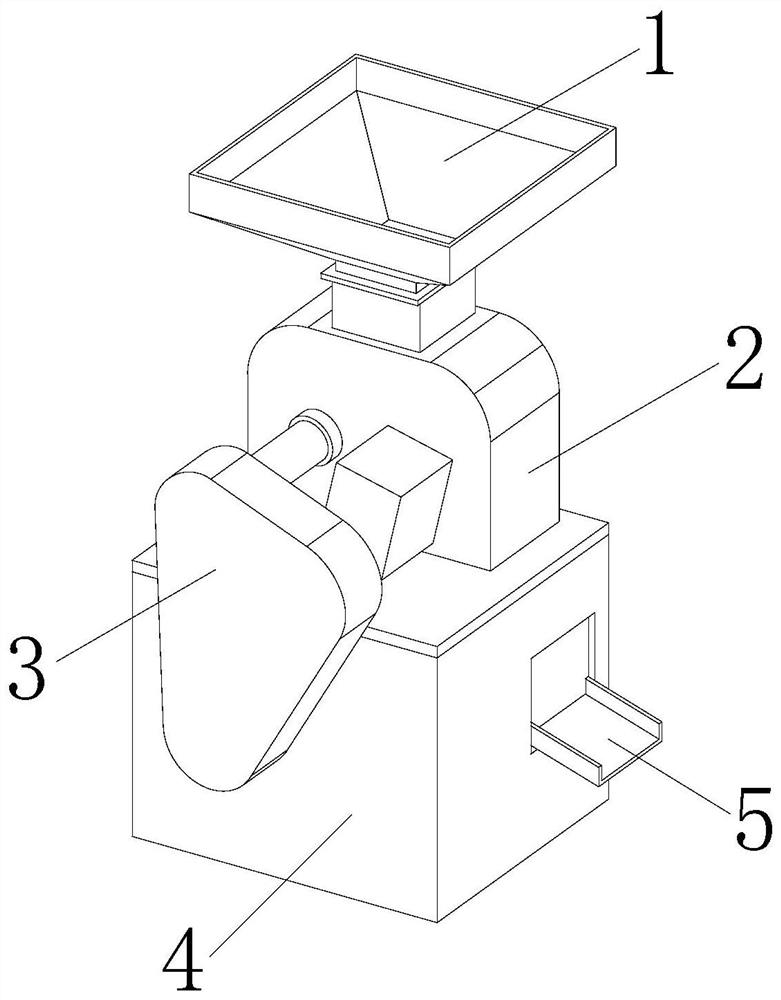

[0024] as attached figure 1 to the attached Figure 5 shown:

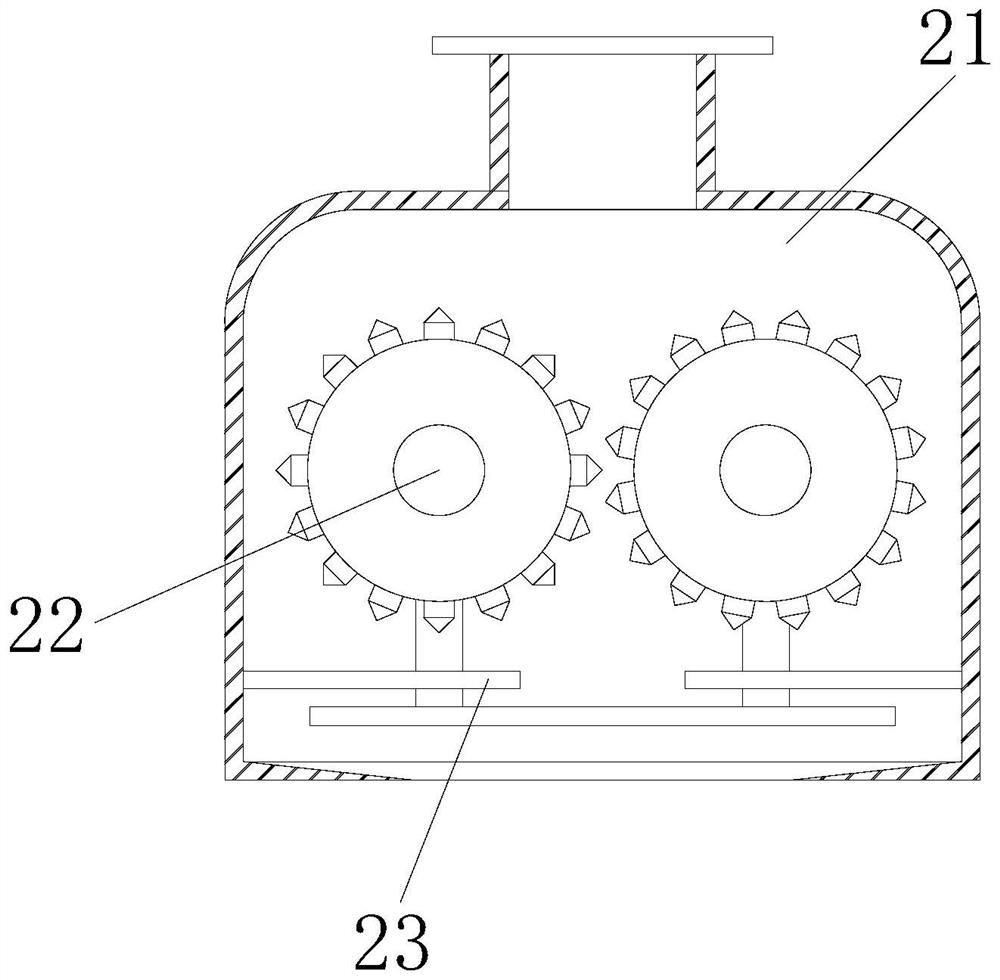

[0025] The present invention is an agricultural cotton hulling machine. Its structure includes a feeding hopper 1, a hulling device 2, a transmission box 3, a feeding box 4, and a discharge plate 5. The feeding hopper 1 is embedded in the hulling device 2. The top is connected with each other, the front end surface of the shelling device 2 is provided with a transmission box 3 and is connected by transmission, the shelling device 2 is fixedly installed on the top of the discharge box 4 and communicated, and the right end of the discharge box 4 is provided with There is a discharge plate 5, and the shelling device 2 includes a separation box 21, a shelling roller 22, and a pushing mechanism 23. The top of the separation box 21 is provided with a feeding hopper 1 and communicates with each other. The shelling roller 22, and the shelling roller 22 is drivingly connected with the transmission box 3, the shelling roll...

Embodiment 2

[0032] as attached Image 6 to the attached Figure 8 shown:

[0033] The pushing mechanism 23 includes a cam 231, a pressing rod 232, a reciprocating mechanism 233, a dispersing mechanism 234, and a connecting frame 235. The cam 231 is arranged inside the middle end of the roller body 221 and rotates synchronously. The lower end of the cam 231 is connected to the pressing The upper end of the rod 232 is in contact with each other, and the pressing rod 232 is fixedly installed on the top of the reciprocating mechanism 233, the outer end of the reciprocating mechanism 233 is welded with the inner wall of the separation box 21, and the lower end of the reciprocating mechanism 233 is welded with the upper surface of the dispersing mechanism 234, so The outer end of the dispersing mechanism 234 is arranged inside the connecting frame 235, the cam 231, the pressing rod 232, the reciprocating mechanism 233 and the dispersing mechanism 234 are all provided with two. The two cams 231...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com