Composition and manufacturing method of special epoxy acrylic resin for ldi photoresist

A technology of epoxy acrylic and composition, which is applied in the field of circuit board production, can solve the problems of slow curing speed, insufficient photolithographic resolution, unfavorable rapid manufacturing, etc., and achieve the effect of convenient heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Such as figure 1 Shown, a kind of composition of epoxy acrylic resin special for LDI photoresist, the composition of this special epoxy acrylic resin of LDI photoresist is made up of the composition of following parts by weight: Dicyclopentadienyloxyethyl acrylate 38 -48 parts, 15-25 parts of polyurethane modified epoxy acrylic resin, 0.5-0.7 parts of triaryl silicone ether, 0.01-0.05 parts of active sensitizer, 0.03-0.05 parts of benzoyl peroxide, acid diffusion inhibitor 0.02-0.05, 2-7 parts of acrylic free radical reactive diluent, 8-13 parts of propylene glycol ether.

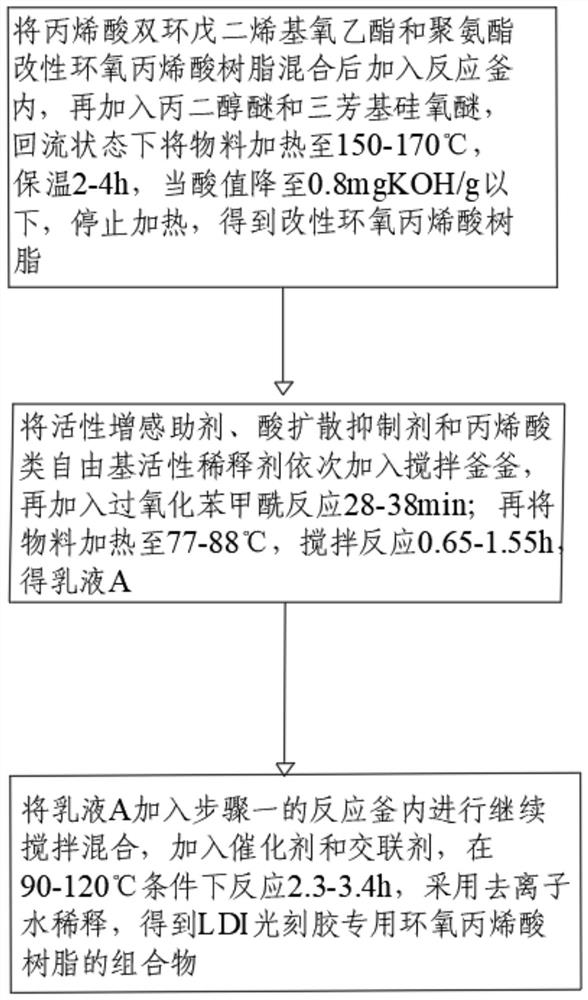

[0045] A kind of manufacture method of the composition of epoxy acrylic resin special for LDI photoresist, manufacture method step is as follows:

[0046] Step 1: Mix dicyclopentadienyloxyethyl acrylate and polyurethane modified epoxy acrylic resin and add them to the reaction kettle, then add propylene glycol ether and triaryl siloxane, and heat the materials to 150-170°C under reflux , keep warm ...

Embodiment 2

[0051] Embodiment 2 is a further improvement to Embodiment 1.

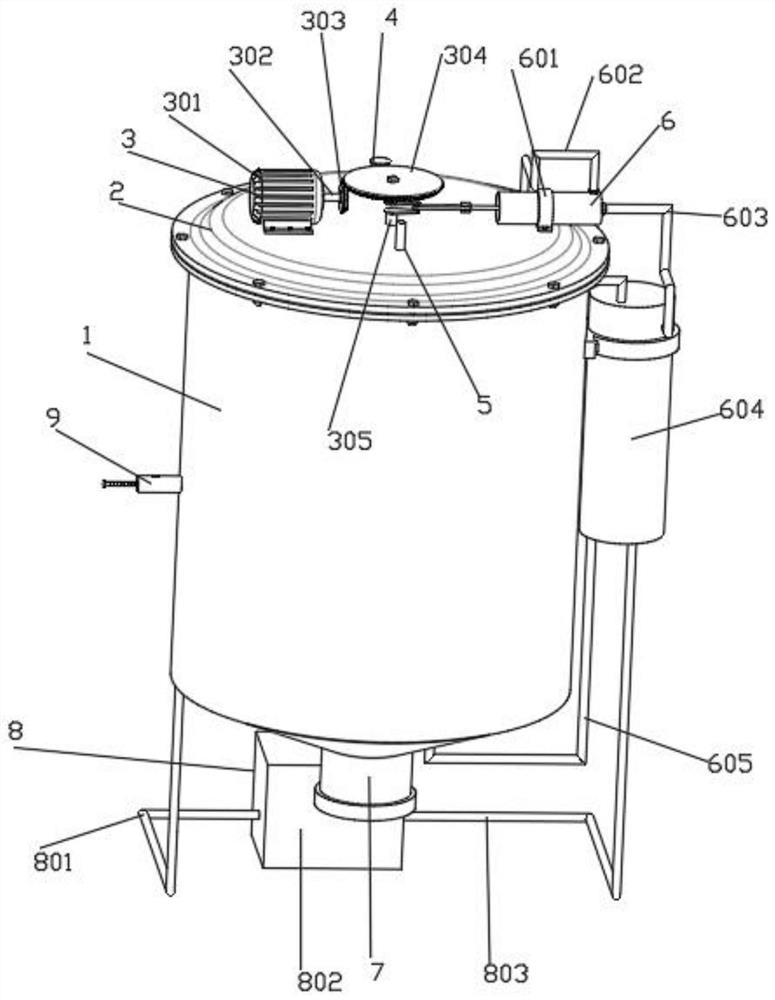

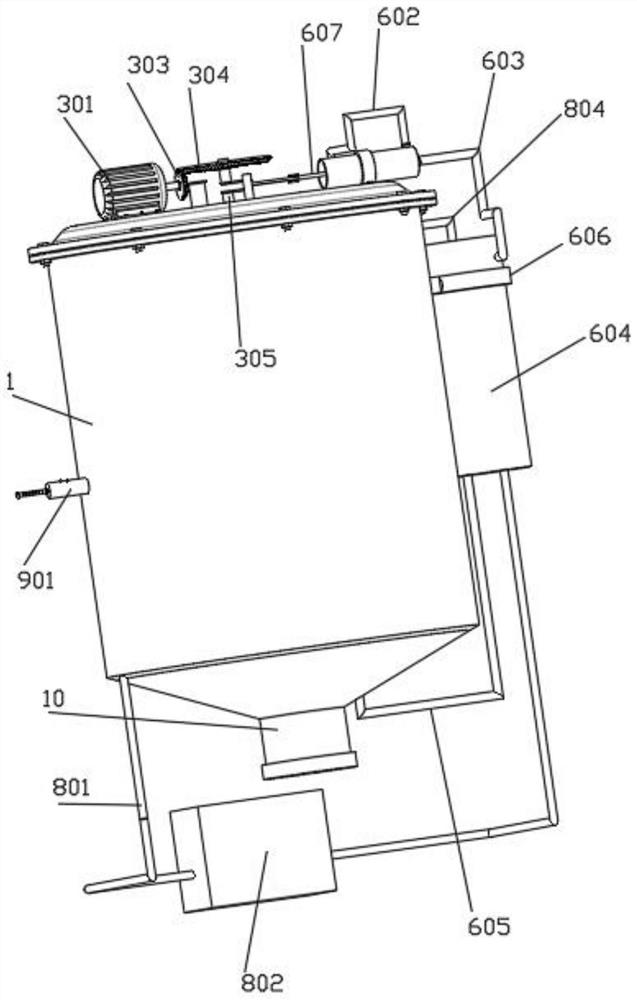

[0052] Such as figure 2 , 3 , 4, 5, 6, 7, 8, 11 shows a kind of manufacturing device of the composition of LDI photoresist special-purpose epoxy acrylic resin, comprises reaction kettle 1, cover plate 2, feed pipe 4, dropper 5 And the third discharge pipe 7, the bottom of the reactor 1 is fixedly connected with the third discharge pipe 7, the top of the reactor 1 is fixedly connected with the cover plate 2, and the top of the cover plate 2 is connected with the stirring structure 3 and the feed pipe 4 And dropper 5, dropper 5 adds emulsion A in the reaction kettle 1, the top of feeding pipe 4 and the bottom of the third discharge pipe 7 are all screwed with caps, stirring structure 3 includes drive motor 301, rotating shaft 302, the first A bevel gear 303, a second bevel gear 304, a crankshaft 305, a stirring plate 306 and a scraper 307, the driving motor 301 is fixedly mounted on the top of the cover plate 2, ...

Embodiment 3

[0056] Embodiment 3 is a further improvement to Embodiment 1.

[0057] Such as figure 2 , 7, 8, 10 The side wall of the reactor 1 is connected with a sampling structure 9, and the sampling structure 9 includes a sampling cylinder 901, a threaded rod 902, a nut 903, a threaded sleeve 904, a sampling hole 905, a connecting bearing 906, a horizontal hole 907, and a sample groove 908, movable column 909, chute 910 and limit slider 911, horizontal hole 907 is fixedly installed on the side wall of reaction kettle 1, and sampling cylinder 901 is fixedly connected in horizontal hole 907, and the top middle end of sampling cylinder 901 is fixedly connected There is a sampling hole 905, the left end of the sampling cylinder 901 is fixedly connected with a threaded sleeve 904, the threaded sleeve 904 is threadedly connected with a threaded rod 902, the left end of the threaded rod 902 is fixedly connected with a nut 903, and the inner end of the threaded rod 902 is fixedly connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com