Symmetrical two-dimensional force sensor and tractor

A force sensor, two-dimensional technology, applied in the field of symmetrical two-dimensional force sensors and tractors, can solve the problem that the sensitivity of the two-dimensional force sensor cannot meet some special requirements, and achieves improved sensitivity, large current output range, and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

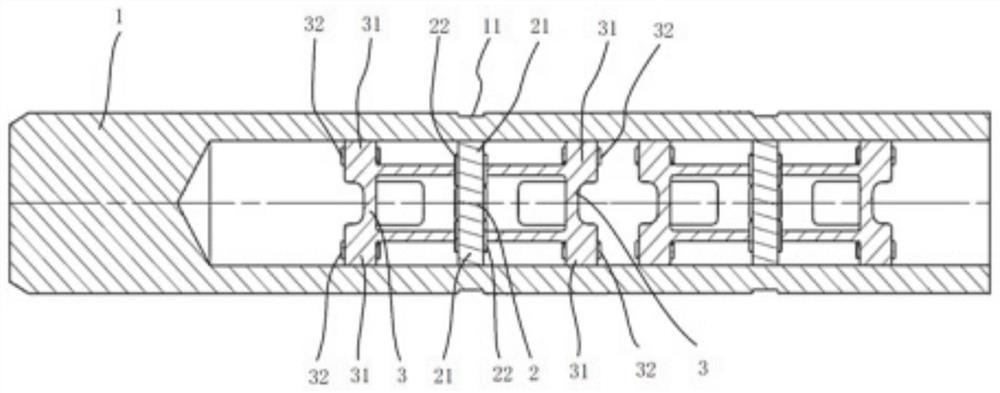

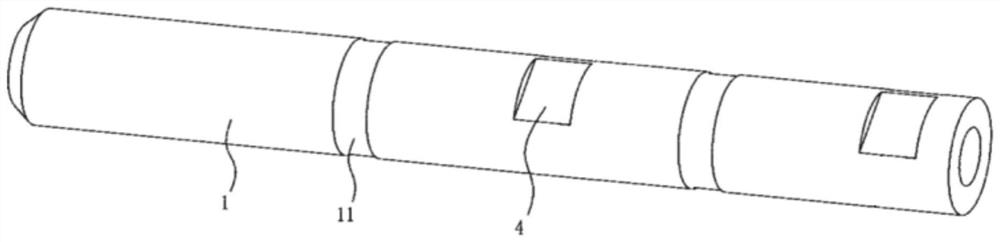

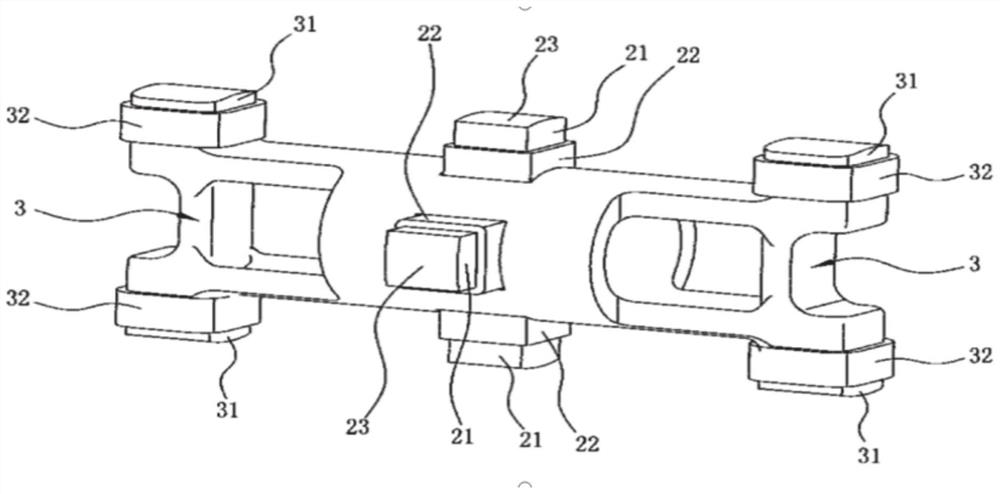

[0025] This embodiment provides a symmetrical two-dimensional force sensor.

[0026] like Figure 1-4 As shown, a symmetrical two-dimensional force sensor includes a bearing cylinder, a first two-dimensional force sensing structure and a second two-dimensional force sensing structure; the first two-dimensional force sensor has the same structure as the second two-dimensional force sensor , and set symmetrically. The load-bearing cylinder 1 in this embodiment can be processed from a circular tube, or can be formed by drilling a pin shaft, and a step or a slot structure 4 can be added on the outer peripheral surface for positioning and installation.

[0027] Since the structure of the first two-dimensional force sensing structure is the same as that of the second two-dimensional force sensing structure, only the specific structure of the first two-dimensional force sensing structure will be described here.

[0028] The first two-dimensional force sensing structure includes an ...

Embodiment 2

[0037] This embodiment provides a tractor.

[0038] A tractor, including a tractor body, adopts the symmetrical two-dimensional force sensor described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com