A dynamic measurement system and method for blade tip clearance based on microwave phase difference ranging

A technology of blade tip clearance and dynamic measurement, which is applied in the direction of measuring devices, using wave/particle radiation, instruments, etc., to achieve the effect of high-precision extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

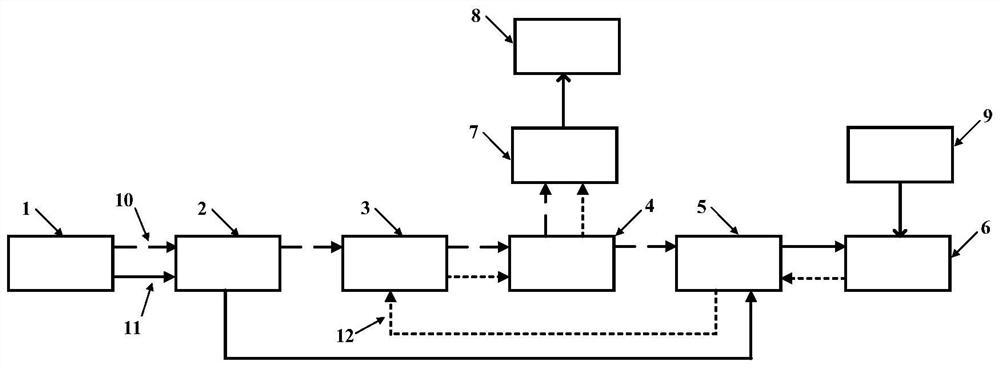

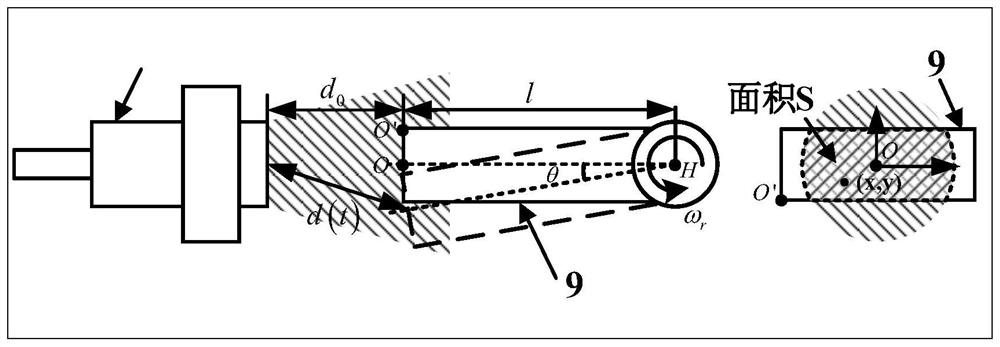

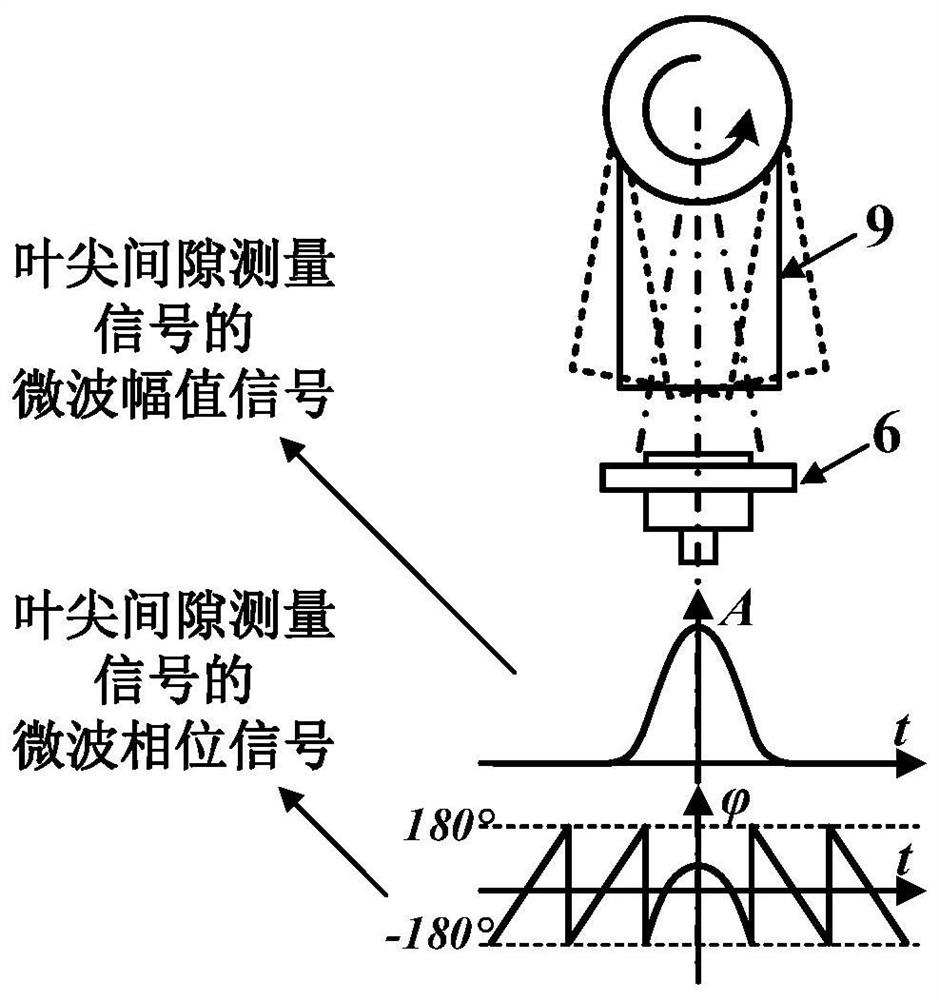

[0037] See figure 1 The present invention provides a tip clearance dynamic measurement system based on microwave phase difference ranging, including a microwave signal generation module 1, a signal power amplification module 2, a signal receiving and mixing module 3, a signal conditioning module 4, a circulator 5, and a microwave sensor 6. Signal acquisition module 7 and computer 8, wherein microwave signal generation module 1 provides radio frequency reference signal 10 and emission signal 11 with the same frequency; blade 9 to be measured reflects emission signal 11 to form reflection signal 12; signal power amplification module 2 uses It is used to amplify the power of the referen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com