A liquid metal temperature control vacuum induction melting device and temperature control method

A vacuum induction smelting and liquid metal technology, which is applied to furnaces, furnace types, lighting and heating equipment, etc., can solve problems such as inaccurate temperature control, and achieve the effects of reasonable structural design and low replacement and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

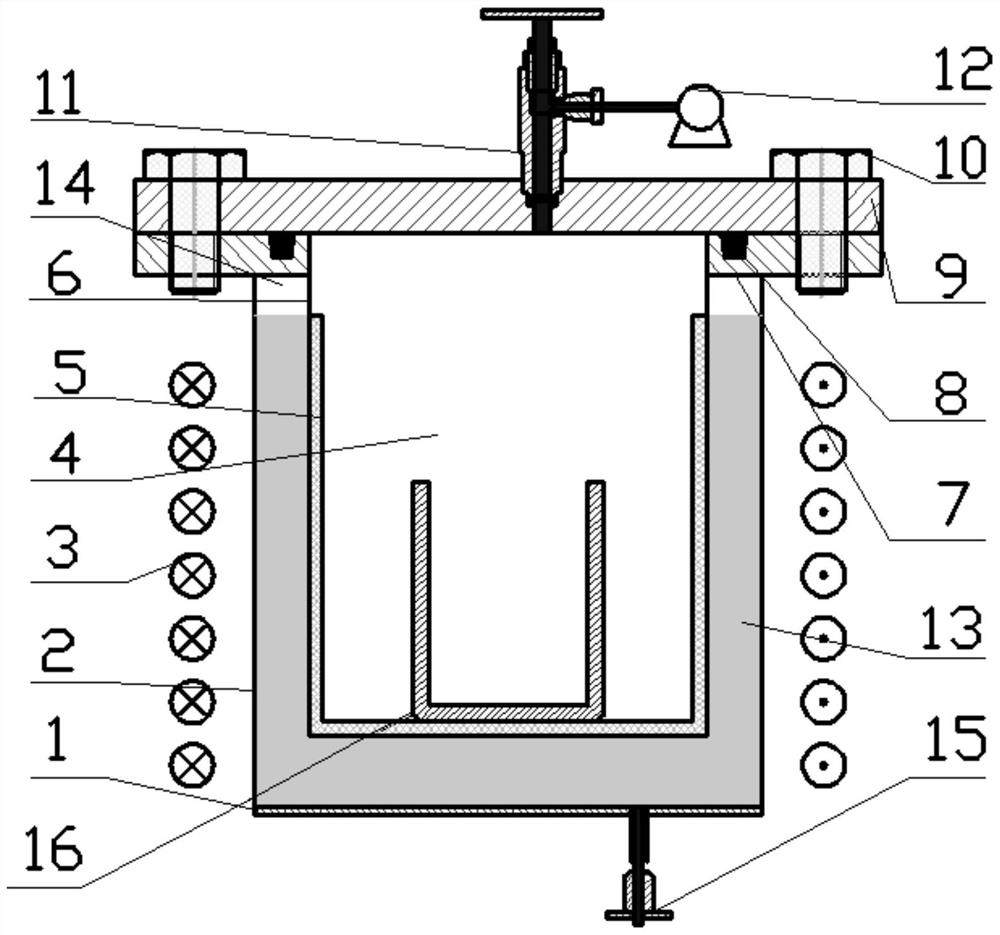

[0033] Embodiment 1: as figure 1 As shown, a liquid metal temperature-controlled vacuum induction smelting device includes a smelting box 2 and a smelting container 16, the smelting container 16 is arranged in the center of the heat preservation chamber 4 of the smelting box 2, and the inner wall of the smelting box 2 is provided with a liquid The metal chamber 6, the liquid metal chamber 6 is filled with liquid metal 13, the outer wall of the smelting box 2 is covered with an induction coil 3, the bottom of the smelting box 2 is provided with a temperature sensor 15, the probe of the temperature sensor 15 is connected to the liquid metal The liquid metal 13 in the metal cavity 6 is in contact, the temperature sensor 15 is externally connected to a temperature controller, and the temperature controller is connected to the induction coil 3;

[0034] The inner wall of the thermal insulation cavity 4 is provided with an thermal insulation layer 5 bonded to the liquid metal cavity...

Embodiment 2

[0052] Embodiment 2: The temperature-controlled vacuum induction smelting device for liquid metal in this embodiment is basically the same as the temperature-controlled vacuum induction smelting device for liquid metal in Embodiment 1, except that the ceramic sealing gasket is silicon nitride sealing gasket or boronized Zirconium sealing gasket, the insulation layer is asbestos net, and the flange is fixedly connected with the cover plate through bolts 14.

Embodiment 3

[0053] Embodiment 3: In this embodiment, the liquid metal temperature-controlled vacuum induction melting device of Embodiment 2 is used to melt magnesium and aluminum alloys. The specific steps are as follows:

[0054] (1) The raw materials Mg, Al, Zn and Mn are respectively weighed according to the mass percentage content of Mg 88%, Al 10%, Zn 1.5% and Mn 0.5%, and then placed in a melting vessel (quartz crucible), and the melting vessel (quartz crucible) is placed in the center of the heat preservation cavity, and the quartz cover plate is connected with the quartz melting box through a flange connection, and the silicon nitride sealing gasket seals the device; the air inside the heat preservation cavity is extracted by a vacuum pump, so that The insulation cavity reaches a vacuum state;

[0055] The temperature controller controls the induction coil to heat the outer wall of the smelting box, and the outer wall of the smelting box conducts heat to the liquid metal Ga in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com