inkjet printing system

An inkjet and ink technology, which is applied in the direction of printing and printing devices, can solve the problems of reducing the smoothness of ink circulation and affecting the volume of the inner cavity of the inkjet nozzle, and achieve the effect of improving the smoothness of ink circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

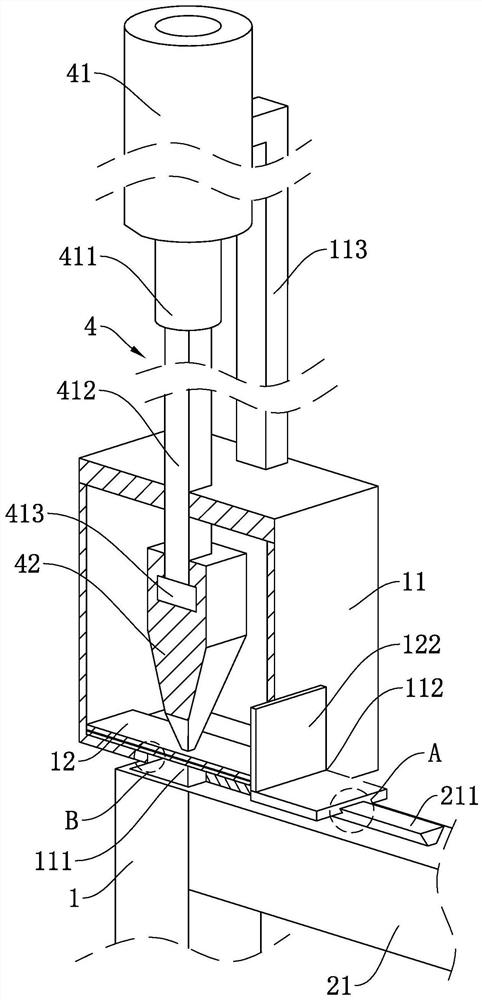

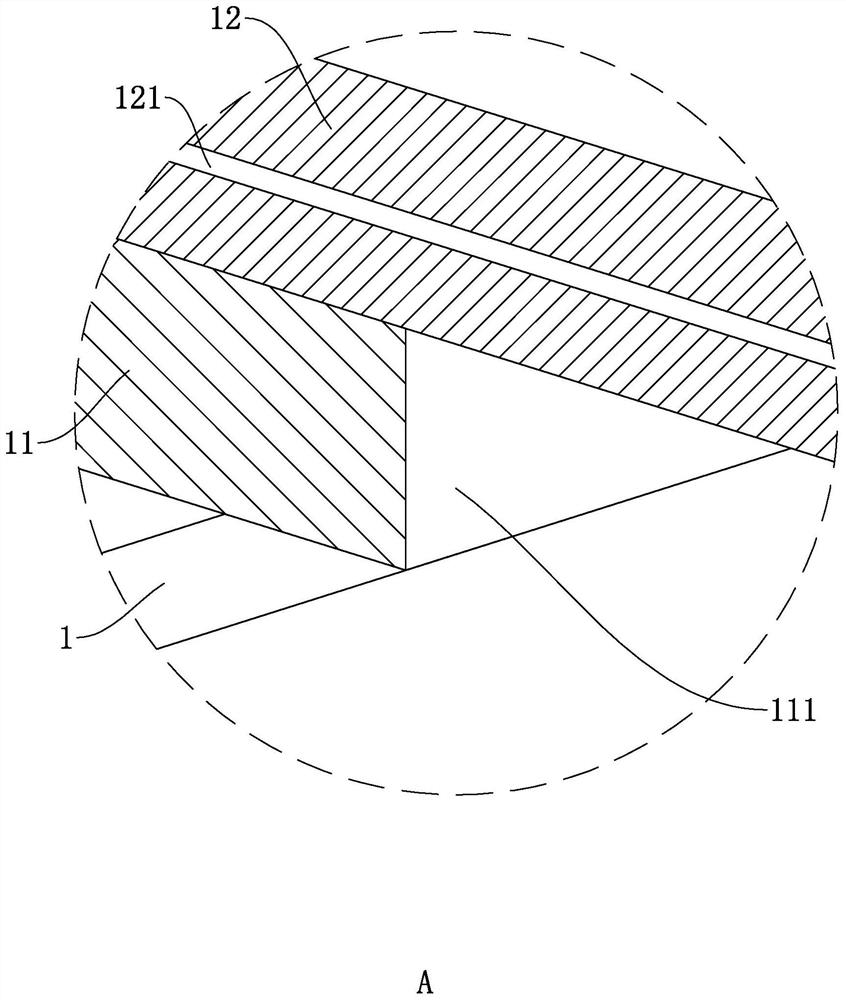

[0038] Contraction below Figure 1-6 Further detailed description of the present application.

[0039] The present application discloses an ink inkjet system.

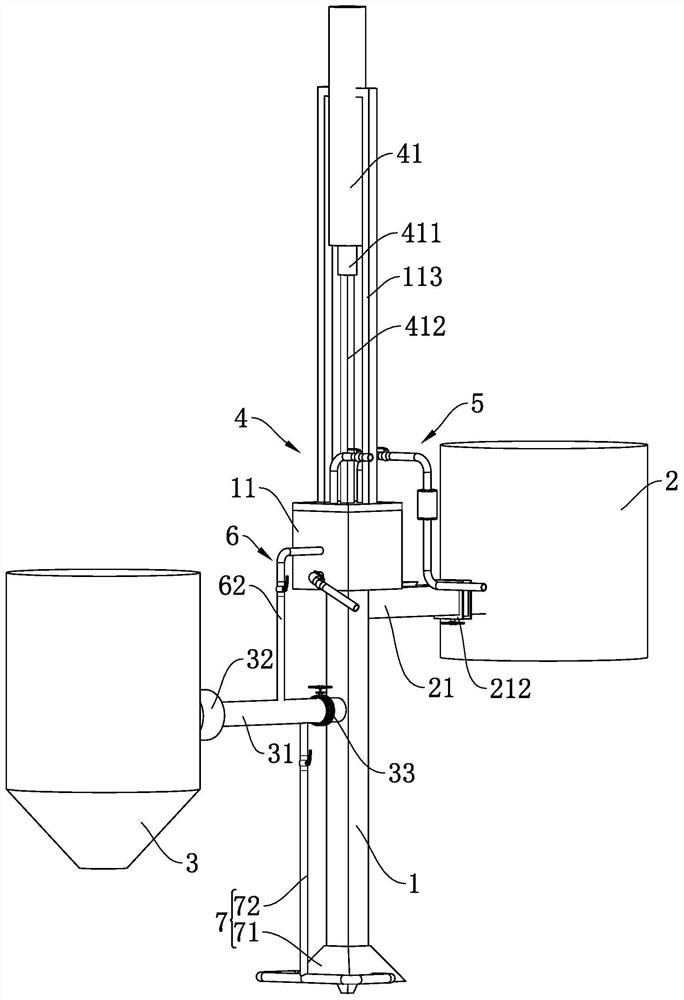

[0040] Refer figure 1 , Ink ink, inkjet system, including the inkjet head 1, the sidewall fixing communication with the inkjet barrel 2 and the dust collecting bucket 3, and the printing head 1 is provided with cleaning assembly 4 and a suction assembly 7; when the inkjet head 1 When in the working state, the ink barrel 2 supplies the ink to the inkjet head 1, and the suction assembly 7 absorbs the irritating gas exiting the inkjet end of the inkjet head 1; when the inkjet head 1 is in an idle state, the dust drum 3 The light impurities in the inkjet head 1 are taken, and the cleaning assembly 4 cleans the impurities bonded in the inner wall of the inkjet head 1, thereby reducing the clogging of the inkjet head 1.

[0041] Refer figure 1, Inkjet head 1 disposed vertically, and has an inkjet head 2 and the fixed communicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com