A glaze proportioning device for ceramic processing

A technology of proportioning and ceramic processing, applied in mixer accessories, transportation and packaging, mixers, etc., can solve the problems of affecting quality, color flow, error-prone, time-consuming and labor-intensive, etc., to achieve the effect of easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

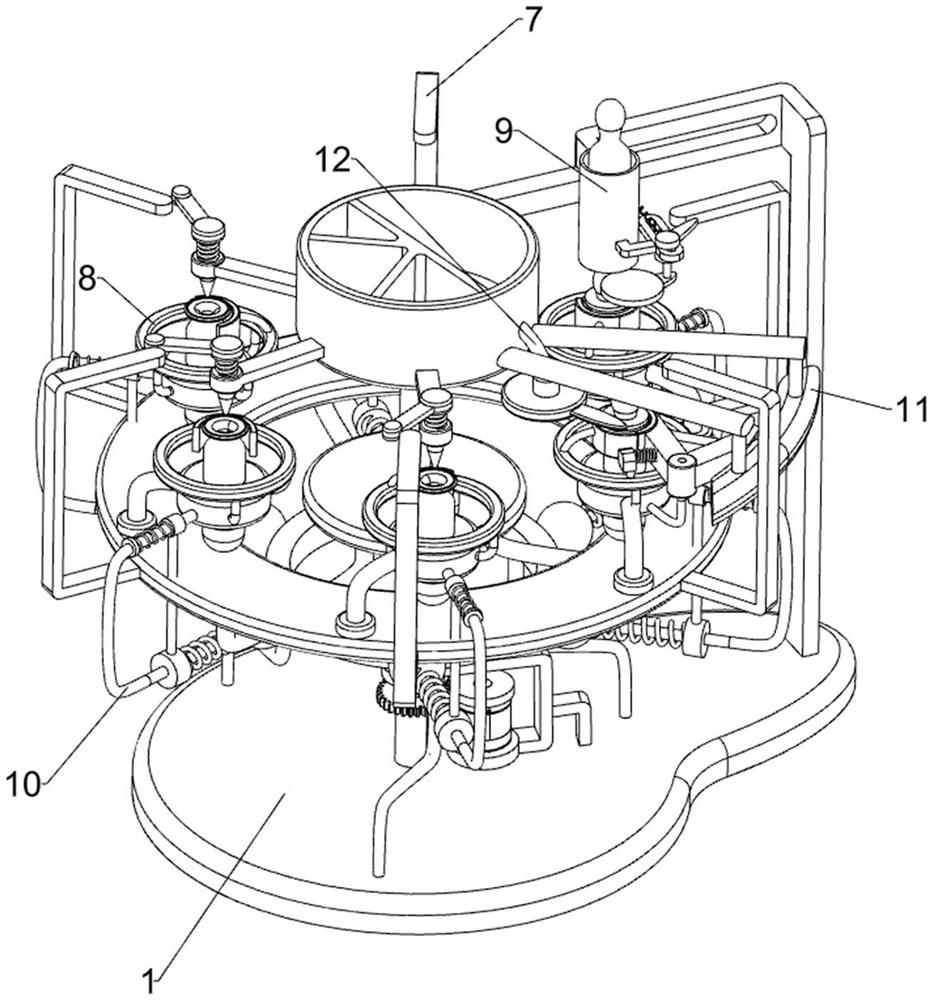

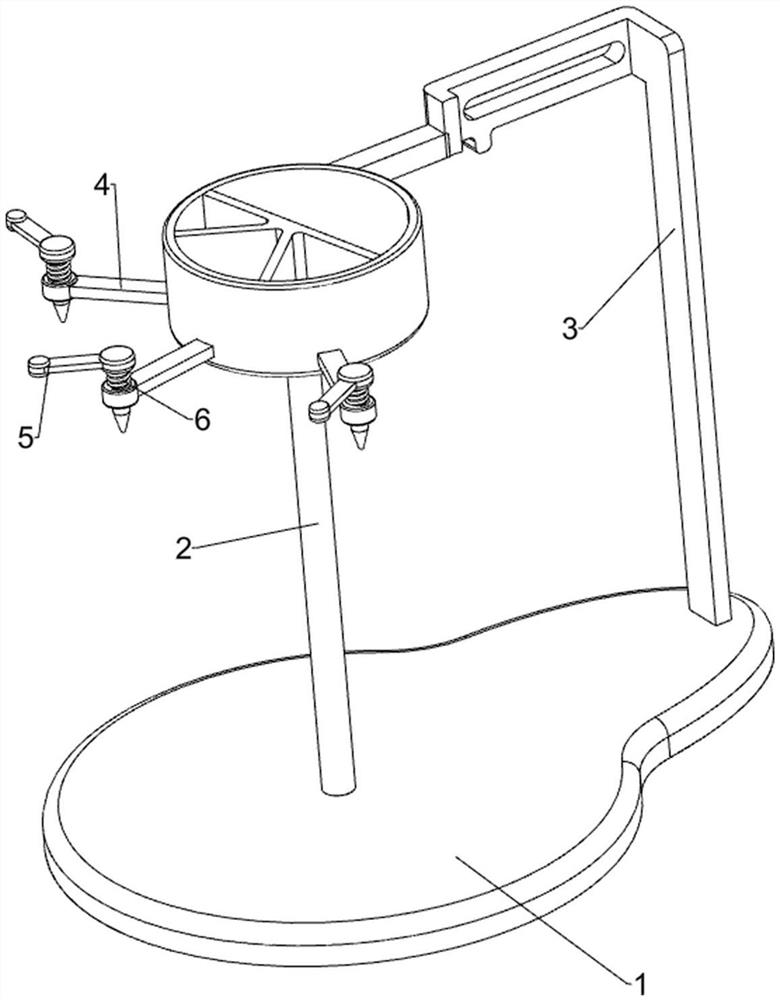

[0046] A glaze proportioning device for ceramic processing, such as figure 1 and figure 2 As shown, it includes a bottom plate 1, a first rotating shaft 2, a first fixing rod 3, a water outlet pipe 4, a switch 5, a first spring 6, a rotating mechanism 7 and a placing mechanism 8, and the top of the bottom plate 1 is rotatably provided with a first rotating shaft 2 , the top right side of the bottom plate 1 is provided with a first fixing rod 3, the upper left side of the first fixing rod 3 is connected with an adjusting frame, the adjusting frame is rotatably connected with the first rotating shaft 2, and the lower part of the adjusting frame is provided with three water outlet pipes 4, A switch 5 is rotatably provided on the outside of the top of the water pipe 4. A first spring 6 is connected between the switch 5 and the top of the water outlet pipe 4, and a rotating mechanism 7 is connected between the lower part of the first rotating shaft 2 and the bottom plate 1. Insti...

Embodiment 2

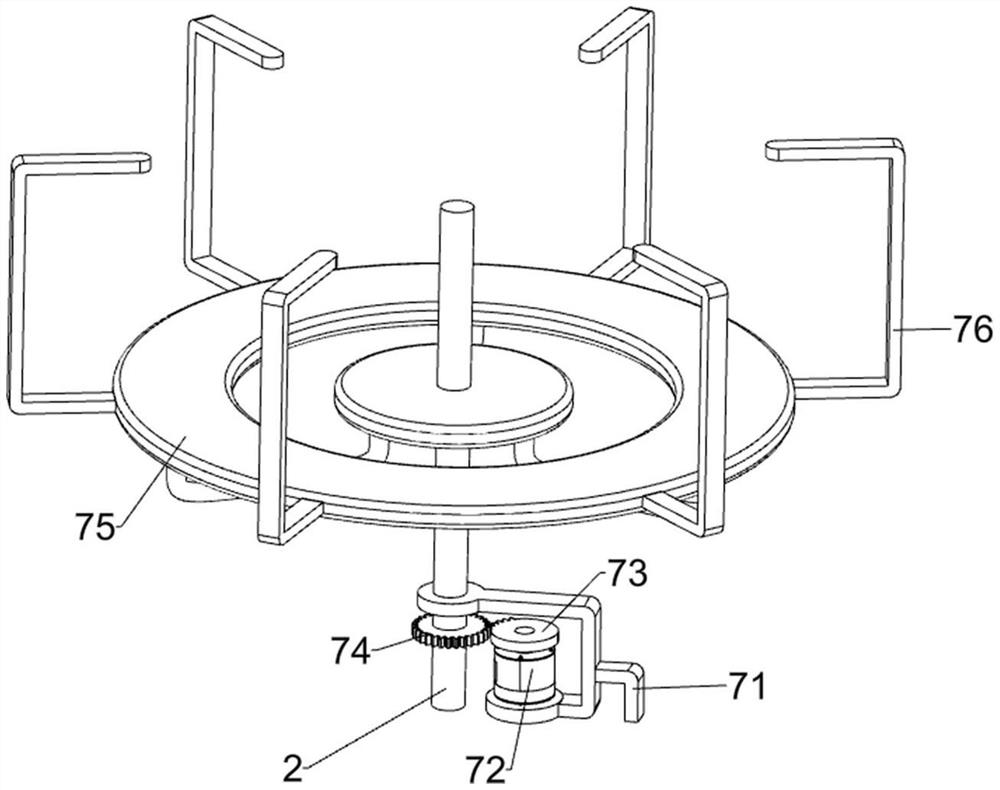

[0049] On the basis of Example 1, as image 3 and Figure 4 As shown, the rotating mechanism 7 includes a second fixed rod 71, a motor 72, a missing gear 73, a spur gear 74, a turret 75 and a touch rod 76. The top of the bottom plate 1 is provided with a second fixed rod 71. The second fixed rod 71 It is rotatably connected with the first rotating shaft 2, the second fixing rod 71 is provided with a motor 72, the output shaft of the motor 72 is provided with a missing gear 73, the lower part of the first rotating shaft 2 is connected with a spur gear 74, the spur gear 74 and the missing gear 73 In cooperation, a turret 75 is arranged in the middle of the first rotating shaft 2 , and six touch rods 76 are evenly arranged on the outer side of the turret 75 .

[0050] The placing mechanism 8 includes a third fixing rod 81, a fixing ring 82, a first fixing block 83 and a placing bottle 84. The top of the turret 75 is evenly provided with six third fixing rods 81, and the interior...

Embodiment 3

[0053] On the basis of Example 2, as Figure 5 to Figure 8 As shown, it also includes a feeding mechanism 9. The feeding mechanism 9 includes a feeding barrel 91, a guide rod 92, a stop ring 93, a telescopic block 94 and a second spring 95. The upper left side of the first fixing rod 3 is provided with a lower A guide rod 92 is provided on the front side of the lower part of the material barrel 91, the guide rod 92 is slidably provided with a blocking ring 93, the upper right side of the blocking ring 93 is provided with a telescopic block 94, and the telescopic block 94 cooperates with the touch rod 76 , a second spring 95 is connected between the upper part of the blocking ring 93 and the first fixing rod 3 .

[0054] The staff can place the placing bottle 84 in the unloading bucket 91. In the initial state, the blocking ring 93 blocks the unloading bucket 91, and the placing bottle 84 will not fall out. The block 94 is rotated forward to drive the blocking ring 93 to move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com