Bubble cutting device

A technology of cutting device and bubble generating device, which is applied in the direction of transportation and packaging, dissolution, dissolution method, etc., and can solve problems such as easy to block and difficult to clear, insufficient number of spun mesh layers, insufficient bubble cutting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing of description, the specific embodiment of the present invention is described in detail:

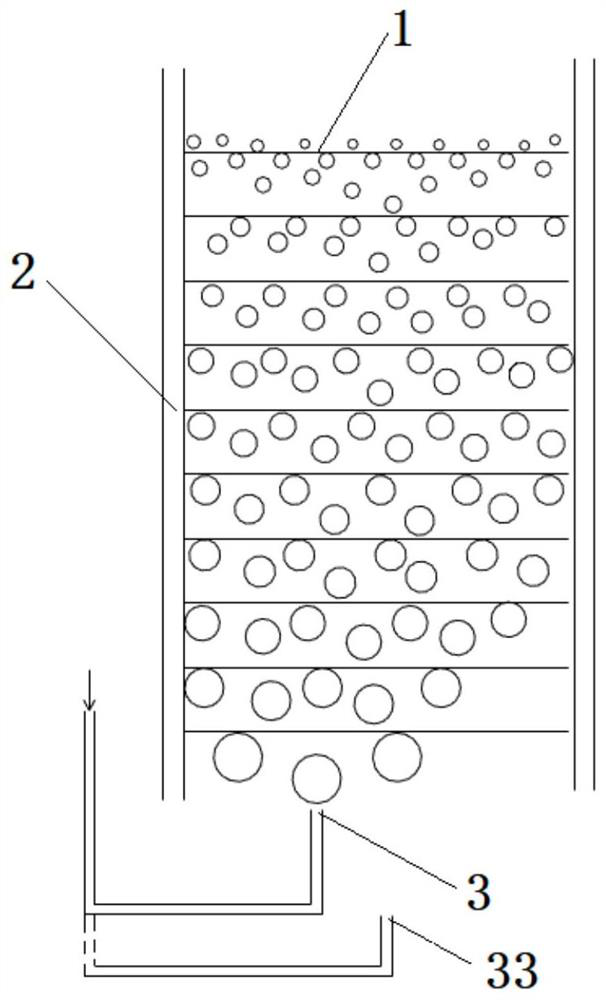

[0027] as attached figure 1 As shown, it includes a multi-layer bubble cutter 1 arranged on a substrate or a pedestal 2, and they are integrally arranged above the bubble outlet 3 of any bubble generating device; the bubble cutter can be a grid of various materials The warp and weft threads can also be monofilaments arranged in parallel, blades with downward cutting edges or other thin sheets; the layer spacing between the cutters of each layer is 1-3 times the grid spacing or wire spacing of the cutters; they It can also be arranged in staggered layers to improve the cutting efficiency; the bubbles emitted by the bubble generating device are continuously cut by the bubble cutter for many times during the floating process, and are broken into more and smaller unstable bubbles to improve the dissolution efficiency .

[0028] Describ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com