Fault processing method and system for centralized exhaust type range hood

A fault handling method and collection-discharging technology, applied in transmission systems, digital transmission systems, heating methods, etc., can solve problems such as potential safety hazards, communication failures, and impacts on customer use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

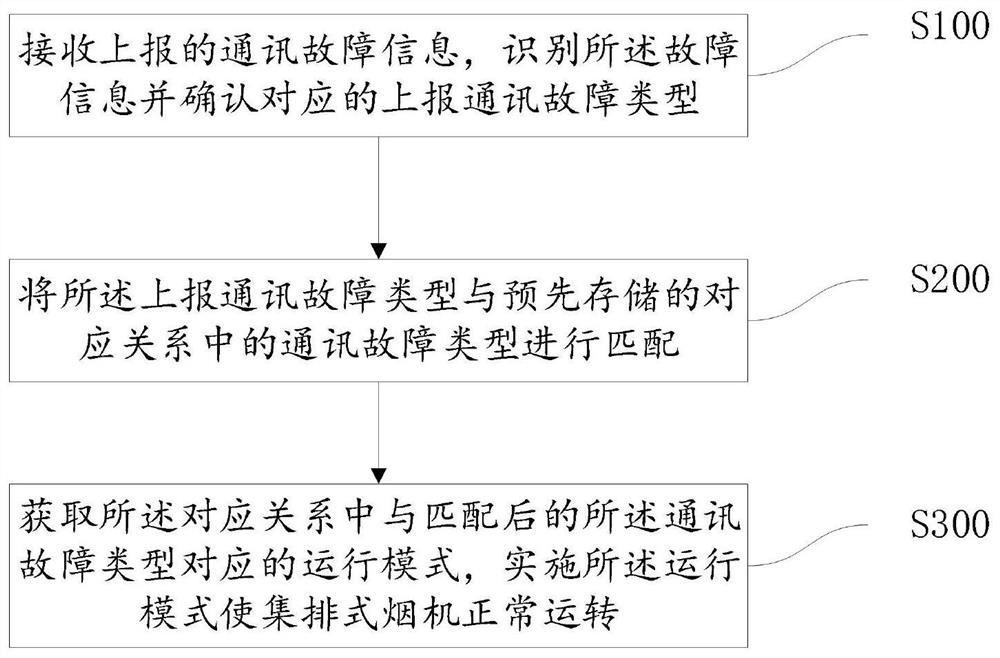

[0050] This embodiment of the present application provides a fault handling method for exhaust smoke machines that can apply different operating modes under faults according to different types of communication faults, such as figure 1 As shown, its method steps include:

[0051] S100. Receive the reported communication failure information, identify the failure information and confirm the corresponding reported communication failure type. In the collection and exhaust smoke machine system, the main controller will regularly report various information to the cloud for inspection. If the inspection is abnormal, it means that there is a communication failure between the main controller and the cloud; in addition, when the system is operating normally, if the main controller When the starting signal of the terminal smoke machine is not received, that is, the starting rate is 0%, the detected pressure of the public flue also does not reach the starting pressure. When the detected st...

Embodiment 2

[0072] This embodiment of the present application provides a system applying the fault handling method of the collection and discharge hood of the present application, such as Figure 5 As shown, it includes a fault processing unit 1 and a collection and exhaust hood unit 2;

[0073] The fault processing unit 1 is configured to receive the communication fault information reported by the collection and discharge hood unit 2, identify the fault information and confirm the corresponding reported communication fault type, and compare the reported communication fault type with the pre-stored matching the communication failure types in the corresponding relationship, and obtaining the operation mode corresponding to the matched communication failure type in the corresponding relationship;

[0074] The collection and exhaust type hood unit 2 is used to implement the acquired operating mode to make the collection and exhaust type hood unit operate normally.

[0075] Such as Image 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com