High-swelling-degree AFL, preparation method and high-swelling-degree AFL ceramic diaphragm

A technology of ceramic diaphragm and swelling degree, which is applied in the direction of electrical components, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of poor contact, affecting the service life of batteries, and small particle size, so as to reduce the change of size and avoid poor interface contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

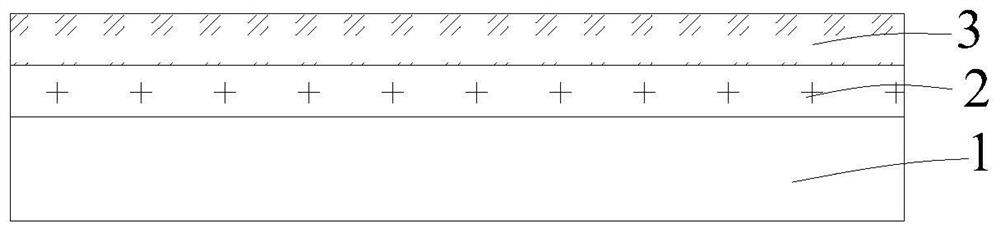

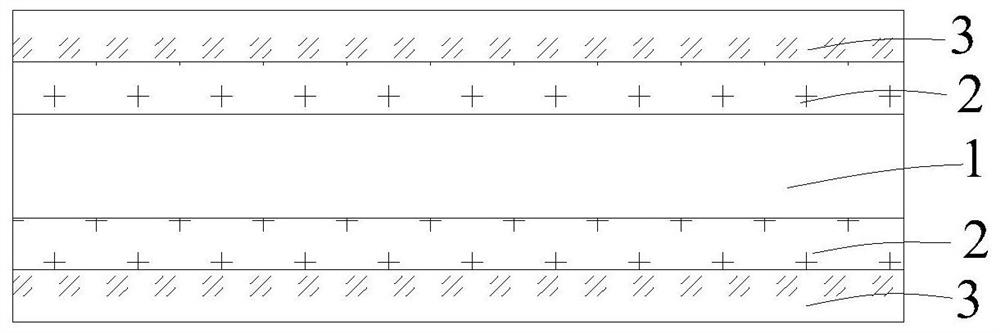

Image

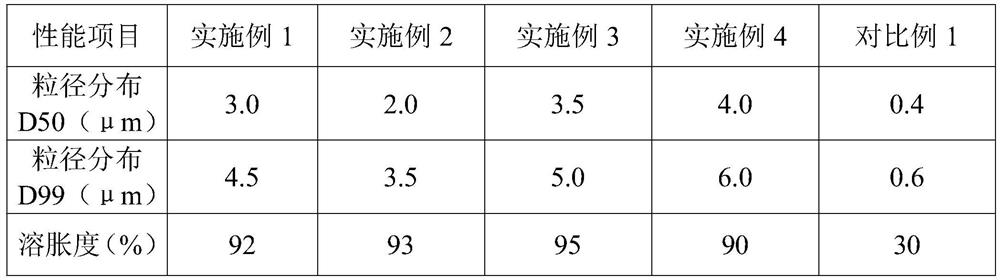

Examples

preparation example Construction

[0025] Further, the present invention also provides a method for preparing AFL with high swelling degree, comprising the following steps: putting PMMA into electrolyte solution for soaking to obtain swollen PMMA; putting swollen PMMA into PAN solution for stirring to obtain PAN-coated PMMA; After drying the PAN-coated PMMA, AFL with high swelling degree was obtained.

[0026] Wherein, optionally, the PMMA may be, but not limited to, spherical PMMA with a molecular weight of 50,000-200,000.

[0027] Optionally, the temperature for soaking the PMMA in the electrolyte solution may be, but not limited to, 40-50° C., and the time may be, but not limited to, 24-72 hours, so as to fully swell the PMMA.

[0028] Optionally, the electrolyte solution may be but not limited to propylene carbonate (PC), ethylene carbonate (EC), diethyl carbonate (DEC) or dimethyl carbonate (DMC).

[0029] Optionally, the drying temperature of the PAN-coated PMMA may be, but not limited to, 40-50° C., so ...

Embodiment 1

[0043] Put 20kg of spherical PMMA with a molecular weight of 100,000 into diethyl carbonate and soak for 48h at 50°C to obtain swollen PMMA; put the swollen PMMA into 10kg of PAN solution with a solid content of 40% and stir to obtain a PAN package. Coated PMMA; After drying the PAN-coated PMMA at 45 °C, AFL with high swelling degree was obtained.

Embodiment 2

[0045]20kg of spherical PMMA with a molecular weight of 50,000 is put into diethyl carbonate and soaked for 72h at 45°C to obtain swollen PMMA; the swelled PMMA is put into 5kg of PAN solution with a solid content of 40% and stirred to obtain a PAN package. Coated PMMA; After drying the PAN-coated PMMA at 40 °C, AFL with high swelling degree was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com