Electrode plate, silicon lithium battery monomer with electrode plate and silicon lithium battery

A technology for electrode plates and lithium batteries, applied in lithium batteries, electrode carriers/collectors, non-aqueous electrolyte batteries, etc., can solve the problems of unsuitable recycling, high consumption of metal materials, soil and water pollution, etc., and achieve easy recycling And reuse, reduce heat, reduce the effect of shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The electrode plate of this embodiment includes a positive electrode plate 3 and a negative electrode plate 6 , and a diatomaceous earth mixture is provided on the plate body composed of the positive electrode plate 3 and the negative electrode plate 6 .

[0047] The pole plate body of the electrode plate is provided with a diatomaceous earth mixture, which may be a diatomaceous earth mixture composed of a diatomite filler in the pole plate body formed by the positive pole plate 3 and the negative pole plate 6 . The diatomite filling body can be used as the diaphragm 2 between the positive electrode plate 3 and the negative electrode plate 6, and the diatomite filling body can also be laid on the outside of the diaphragm 2 provided between the positive electrode plate 3 and the negative electrode plate 6 respectively.

[0048] The pole plate body of the electrode plate is provided with a diatomite mixture, and it can also be provided with a diatomite mixture composed of a ...

Embodiment 2

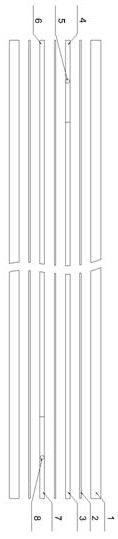

[0050] The electrode plate of this embodiment, refer to Figure 1-Figure 3 , according to the attached figure 1 The sequence in laying diatomite coating 1, a layer of separator 2, a layer of positive electrode plate 3, a layer of separator 2, a layer of negative electrode plate 6, a layer of separator 2, a layer of diatomite coating 1, Compact it, and fold and stack it according to the bending and folding method shown in the figure to make an electrode plate.

[0051] One end of the positive electrode plate 3 is connected with a positive electrode tab 4 through which a positive output line 5 is drawn out, and the opposite end of the negative electrode plate 6 is connected with a negative electrode tab 7 through which a negative output line 8 is drawn out.

[0052] During the implementation of the present invention, the electrode plates can be stacked in multiple layers, that is, one layer of diatomite coating, one layer of diaphragm 2, one layer of positive electrode plate 3,...

Embodiment 3

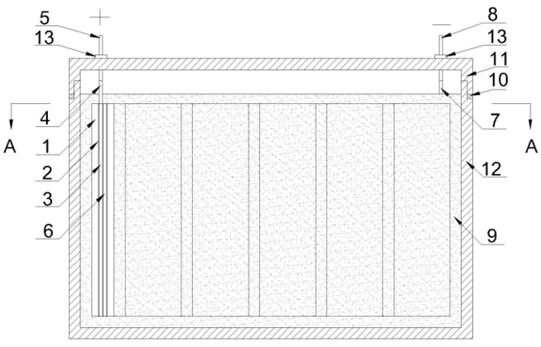

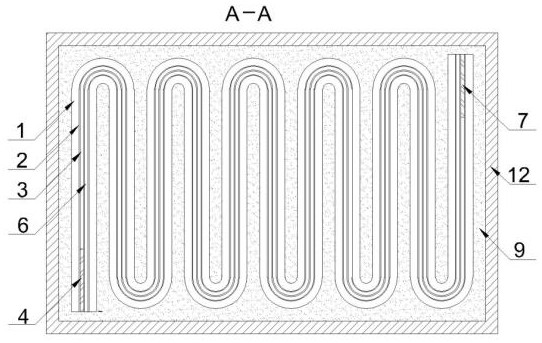

[0054] For the silicon-lithium battery cell of this embodiment, refer to the attached Figure 2-5 , including the electrode plate of Example 1 and the battery inner case 12 for accommodating the electrode plate, a layer of diatomaceous earth filling body 9 is placed at the bottom of the battery inner case 12, and the electrode plate is vertically placed into the filled diatomaceous In the center of the battery inner casing 12 of the earth filling body 9, the positive electrode tab 4 and the negative electrode tab 7 face upward, and the diatomite filling body 9 is filled around the electrode plate and in the gap, and the diatomite filling body 9 is evenly densely packed. Solidly fill the gap between the electrode plate and the battery case, and then spread a layer of diatomaceous earth filler 9 on the electrode plate, exposing the positive electrode tab 4, the negative electrode tab 7, the positive output line 5, and the negative output line 8. The positive output line 5 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com