Online high-temperature dust removal equipment based on biomass micron fuel garbage hydrogen production furnace

A high-temperature dedusting and biomass technology, applied in the field of dedusting equipment, can solve the problems of shortening the service life of the pipeline, difficult to clean the dust, high temperature of the pipeline, etc., and achieve the effect of prolonging the service life and increasing the pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

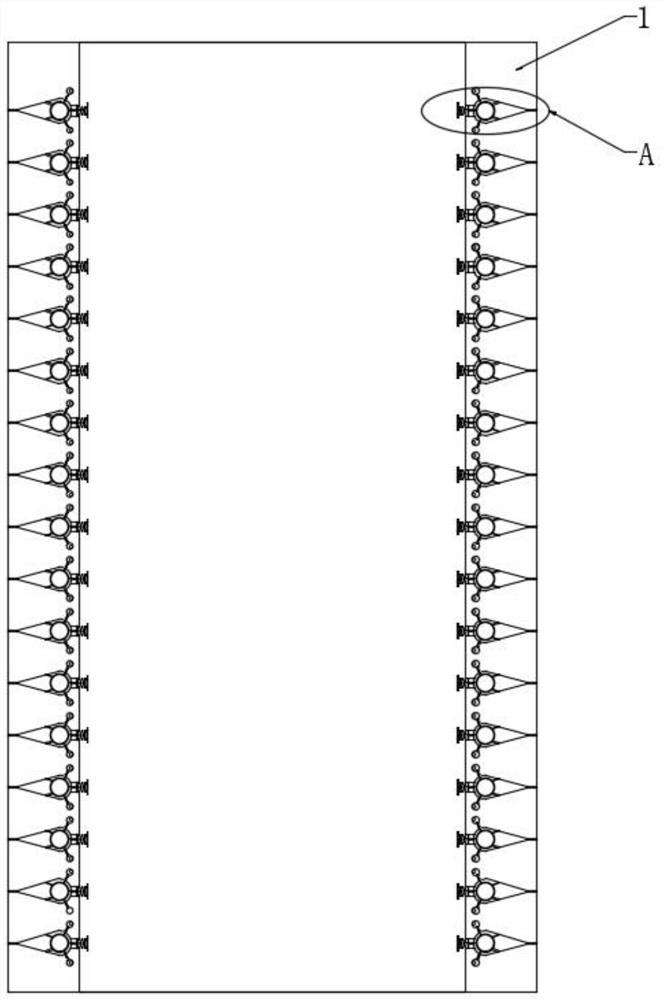

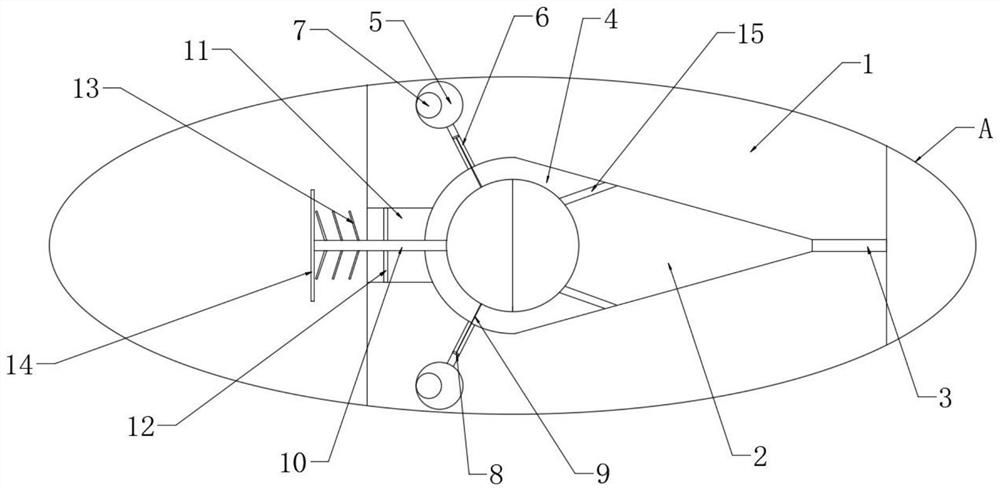

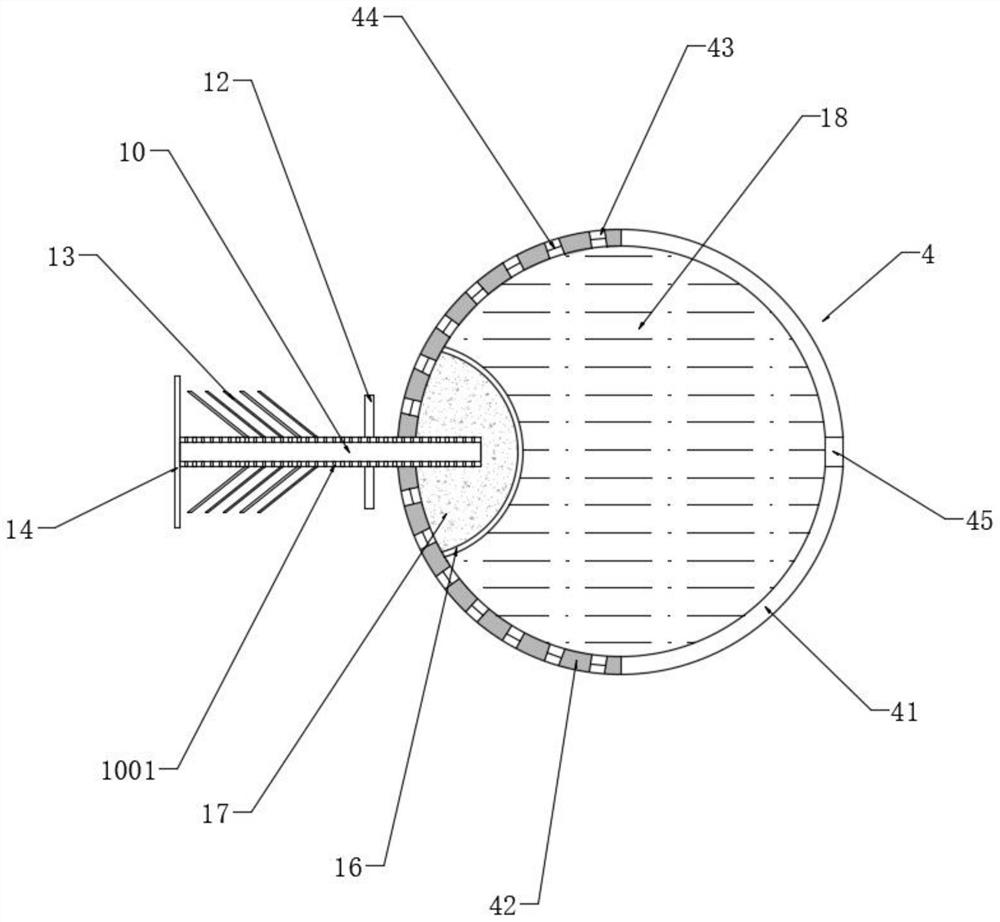

[0043] See figure 1 An online high-temperature dust removing device based on biomass microfuel wasteworm, including smoke pipe 1, and a plurality of uniformly distributed storage cavities 2 on the smoke pipe 1, and the smoke pipe 1 is located in multiple deposit fluids. The upper right end of the cavity 2 has a suction aqueous hole 3 in which the inner portion of the storage chamber 2 is opened. The inner portion of the suction water hole 3 is attached, and the smoke pipe 1 is located on both sides of the storage liquid cavity 2. The vent cavity 5 is opened between the flow chamber 2, and the interior of the two extravasive cavity 5 is mounted, and the inside of the lumen 6 is slidably connected to the piston 8, the piston 8 away from the expansion airbag 7 end The fixing rod 9 is fixedly connected, and the other end of the push rod 9 is fixed to the storage mechanism 4.

[0044] See Figure 2-3 The deposit mechanism 4 includes a first cushion 41 and a second cushion 42 that is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com