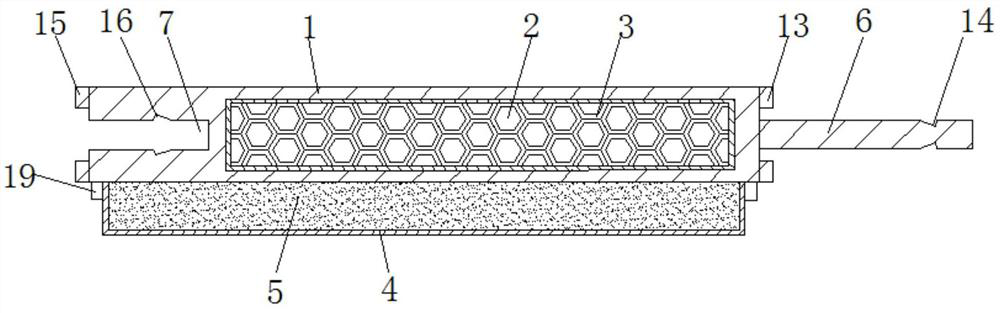

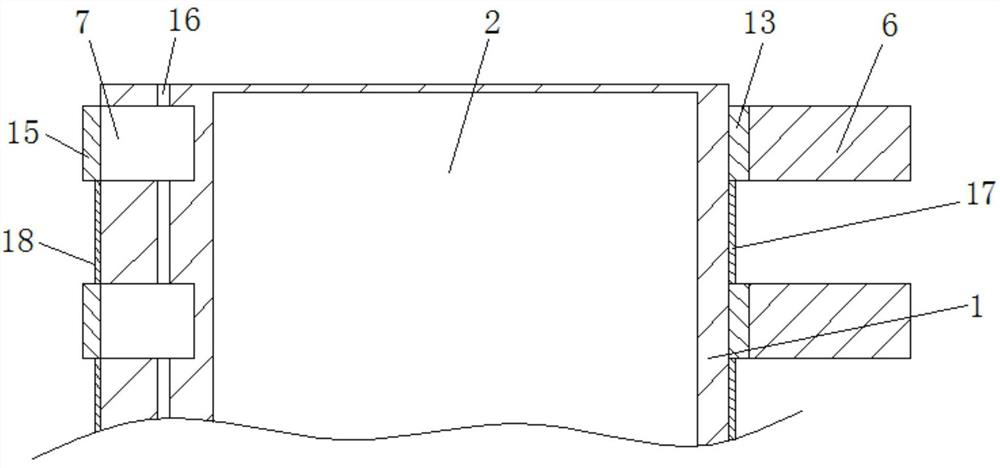

Assembly type integrated thermal insulation wallboard

A thermal insulation wall panel and assembly technology, applied in walls, buildings, building components, etc., can solve the problems of difficult to ensure the aesthetics of the wall, the ventilation and heat preservation of the wall panel and the strength defect, and increase the weight of the wall, so as to achieve a simple structure Reliable, improved strength and aesthetics, and reduced operational difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

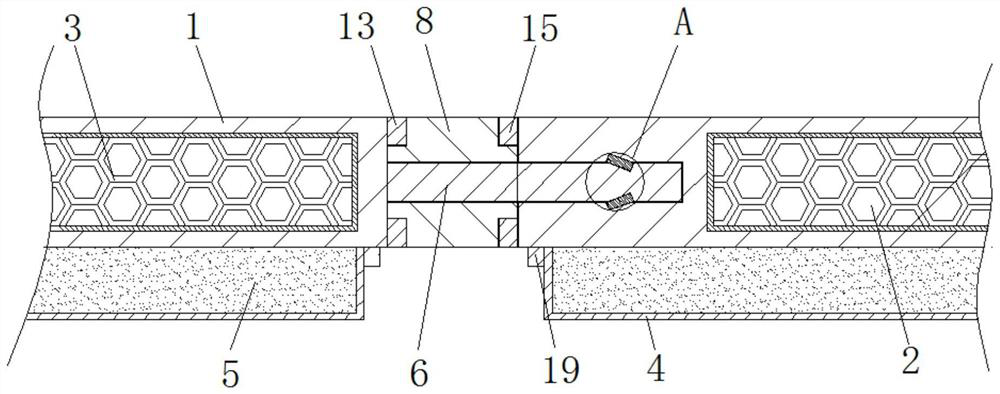

[0036] In actual application, the user selects an appropriate number of main wall 1 and connectors 8 and assembles them in a suitable place. First, the first connector 8 is placed, and then the connecting rod on one side of the main wall 1 6 Align the corresponding connecting through holes 10 and pass them through until the first clamping bar 13 enters the first clamping groove 11, and then align one end of the connecting groove 7 of the adjacent main wall 1 with the connecting rod 6, And push to make the connecting rod 6 enter the connecting groove 7 to complete the connection installation, and finally the limit rod 9 is inserted into the inside through the top of the second limit groove 16, and the limit rod 9 is inserted through a plurality of connecting grooves 7 in turn, and finally all pass through the second limit groove 16. The positioning and installation of the first limiting groove 14 and the second limiting groove 16 are completed, that is, the two main walls 1 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com