Pole pit excavation device for electric power engineering

A technology of electric power engineering and input rods, which is applied in the direction of earth movers/shovels, construction, etc., can solve the problems of inability to dig thick or deep rod pits, and inapplicability, so as to improve excavation efficiency and service life , the effect of strong output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

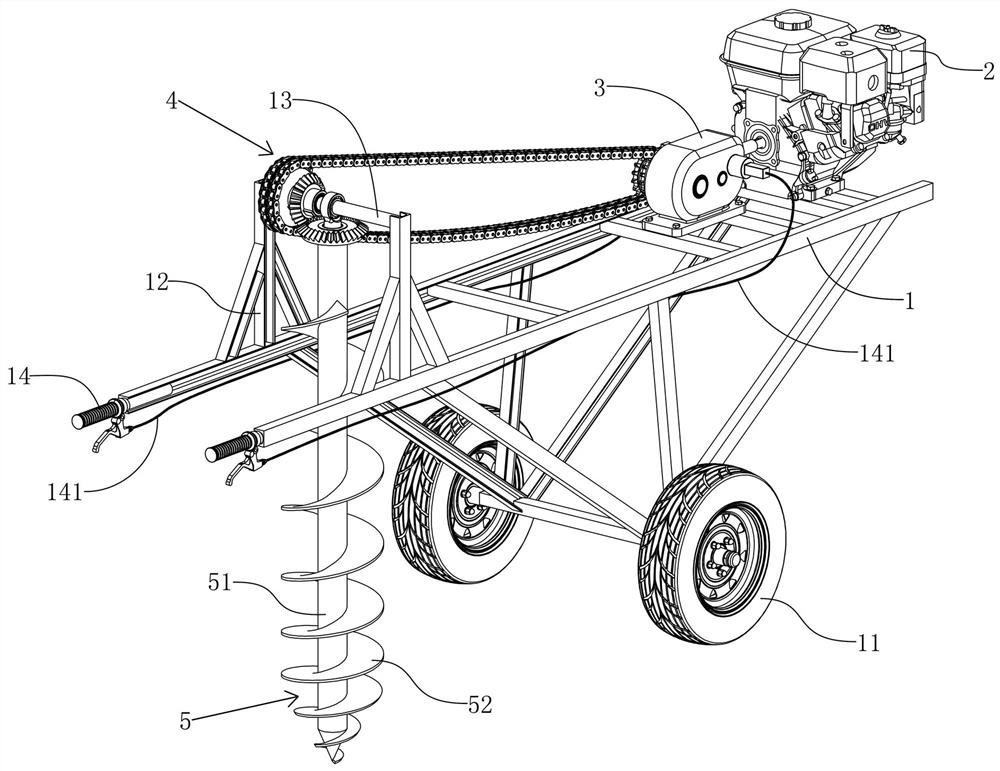

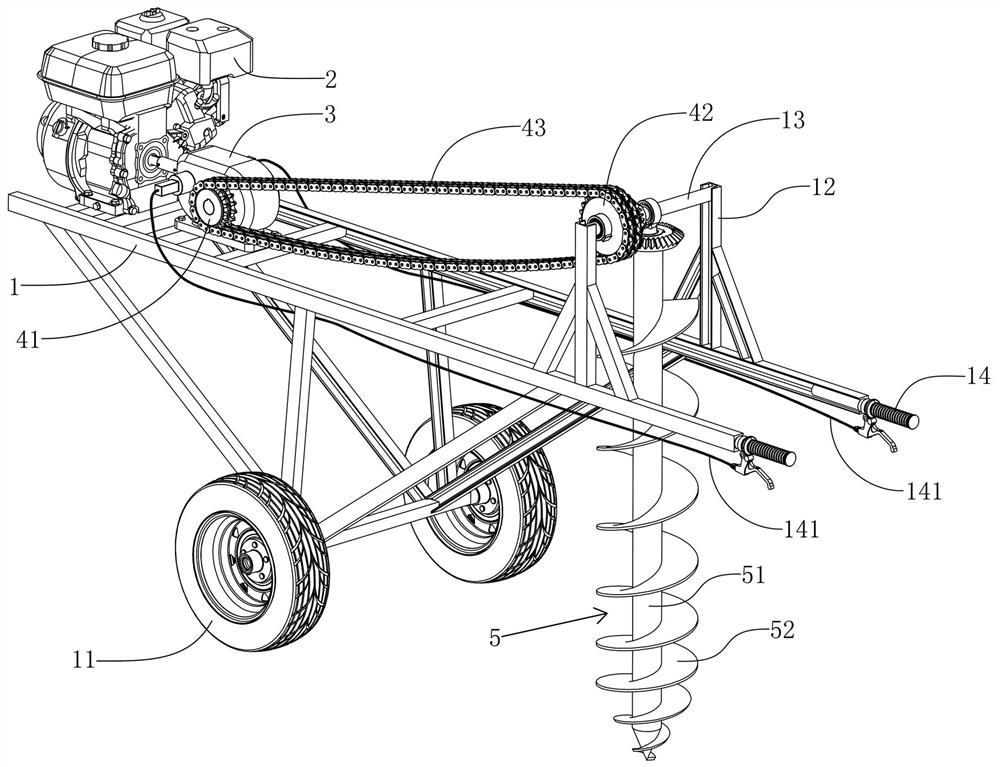

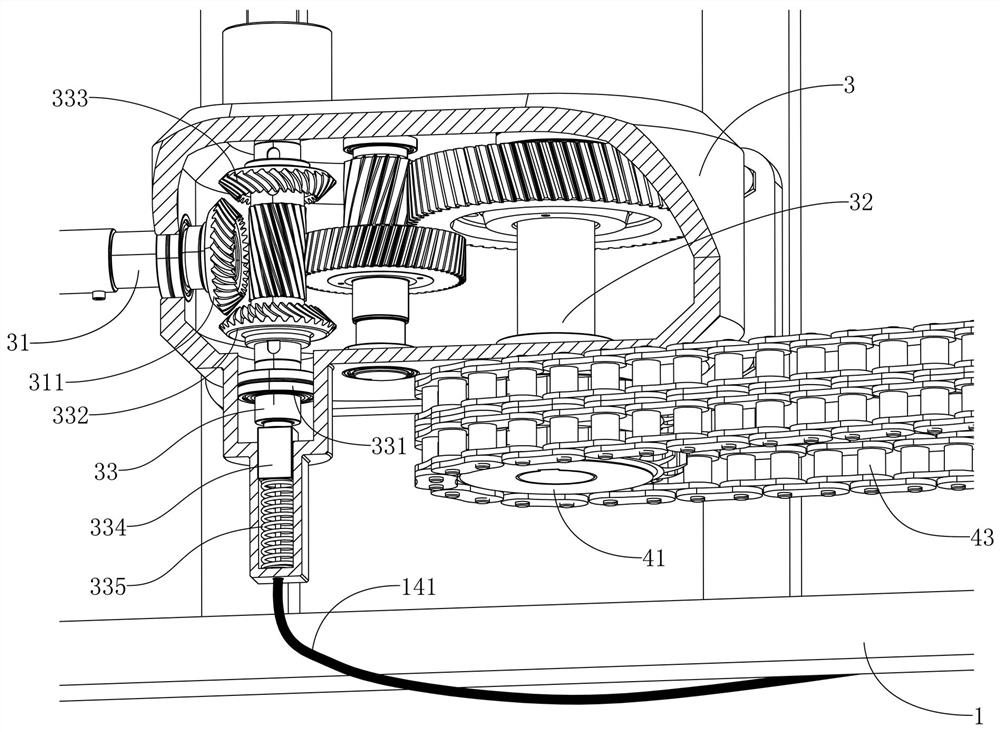

[0046] refer to Figure 1-Figure 4 , The rod pit excavation device for power engineering provided in this embodiment includes a vehicle frame 1 , a driving mechanism 2 , a deceleration mechanism 3 , a transmission mechanism 4 and an excavating mechanism 5 .

[0047] The vehicle frame 1 adopts a steel frame structure, the lower part is an inverted triangular support structure, and a wheel 11 is respectively arranged on both sides of the lower part; vertical support rods 12 are vertically fixed on both sides of the upper part of the front end of the vehicle frame 1, and two vertical support rods A horizontal connecting rod 13 is fixedly connected to the top of the rod 12, and the horizontal connecting rod 13 is a cylindrical rod. The vehicle frame 1 of this embodiment is welded by channel steel, of course, it can also be welded by other profiles such as square steel and angle steel in actual implementation.

[0048] The driving structure 2 is fixedly arranged on the upper part ...

Embodiment 2

[0058] refer to Figure 5 Compared with Embodiment 1, the excavating mechanism 5 of the pole pit excavation device for electric power engineering provided by this embodiment has been improved as follows: the bottom of the spiral piece 52 is provided with bucket teeth 55, and the bottom end of the central rod 51 is provided with an auger bit 56 .

[0059] The bucket teeth 55 are fixed on the bottom edge of the helical blade 52 and are shovel-shaped and made of wear-resistant alloy; the auger bit 56 is fixed on the bottom of the central rod 51 and is a conical auger bit.

[0060] The auger bit 56 of the excavating mechanism 5 in this embodiment can play a positioning role, and at the same time, it can loosen the soil layer after excavation, so that the bucket teeth 55 and the spiral blades 52 can excavate the soil layer. The bucket teeth 55 are made of wear-resistant materials, which can not only improve the excavation efficiency, but also protect the spiral blade 52 .

[0061...

Embodiment 3

[0063] Compared with Embodiment 2, the rod pit excavation device for electric power engineering provided by this embodiment has the following improvements: the excavating mechanism 5 can be used in combination with multiple sections.

[0064] When the multi-section excavating mechanism 5 is used in combination, the excavation depth of the pole pit can be improved, and it is suitable for some higher electric poles to be used for planting poles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com