A method for producing wool fabric with high whiteness and low strength loss

A high whiteness, fabric technology, used in textiles and papermaking, etc., can solve the problems of high strength damage and easy yellowing of wool, and achieve the effect of improving whiteness, improving fabric whiteness and reducing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

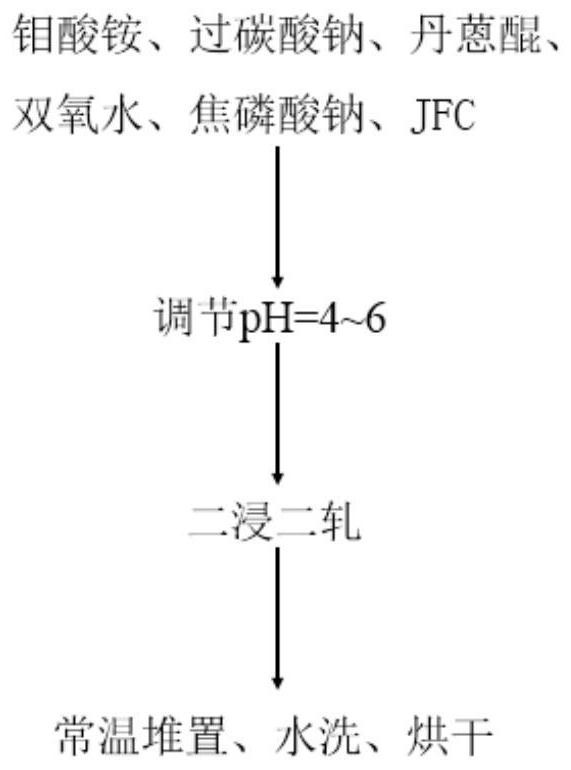

Embodiment 1

[0036] Hydrogen peroxide treatment is used to produce wool fabrics with high whiteness and low strength loss. The method of cold stacking, combined with ammonium molybdate, sodium percarbonate and danthraquinone, makes the wool fabric react slowly under mild treatment conditions, and improves the whiteness of the fabric. At the same time, it also avoids the damage of high temperature and high pH to wool fabric. The isoelectric point of wool is around 4.8, acid-resistant but not alkali-resistant, and the pH value near the isoelectric point can reduce the damage to wool. If the pH value is too high or too low, it will cause damage to wool to a certain extent, and will affect the wool. Therefore, it is necessary to explore the effect of the pH value of the bleaching solution on the bleaching effect of wool.

[0037] Bleach solution composition: 30% hydrogen peroxide 200mL / L, ammonium molybdate 0.05g / L, sodium percarbonate 2.5g / L, danthraquinone 10g / L, sodium pyrophosphate 2g / L, J...

Embodiment 2

[0043] Hydrogen peroxide is difficult to bleach under low temperature and low pH conditions, and usually needs to be bleached under higher temperature (>60°C) and alkaline (pH>10) conditions. The addition of low-temperature activator-ammonium molybdate, by activating hydrogen peroxide, generates a peroxyacid with stronger oxidation ability than hydrogen peroxide, which can achieve better bleaching effect, so different amounts of ammonium molybdate were explored Influence on wool bleaching performance.

[0044] Bleach solution composition: 30% hydrogen peroxide 200ml / L, ammonium molybdate 0.01-0.2g / L, sodium percarbonate 2.5g / L, danthraquinone 10g / L, sodium pyrophosphate 2g / L, JFC 2g / L, The pH is 5.5. Concrete operation process is with embodiment 1.

[0045] According to GB / T 8424.2-1997 "Instrumental Evaluation Method for Relative Whiteness of Textiles" and ASTM D5035-2006 (2008) e1 "Tensile Properties of Textile Fabrics: Determination of Breaking Strength and Elongation at ...

Embodiment 3

[0049] The synergistic agent—the reaction of sodium percarbonate and hydrogen peroxide can also generate a peroxyacid, which has stronger oxidizing properties than hydrogen peroxide and can achieve better bleaching effect. Therefore, different processes have been explored. The effect of the dosage of sodium carbonate on the effect of wool bleaching.

[0050] Bleach solution composition: 30% hydrogen peroxide 200ml / L, ammonium molybdate 0.05g / L, sodium percarbonate 0-10g / L, danthraquinone 10g / L, sodium pyrophosphate 2g / L, JFC 2g / L, pH The value is 5.5. Concrete operation process is with embodiment 1.

[0051] According to GB / T 8424.2-1997 "Instrumental Evaluation Method for Relative Whiteness of Textiles" and ASTM D5035-2006 (2008) e1 "Tensile Properties of Textile Fabrics: Determination of Breaking Strength and Elongation at Breaking by Strip Method", the treated The bleaching effect of wool fabric is shown in Table 3. It can be seen that the bleaching effect of wool fabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com