Double-stage injection type brush handle injection molding equipment

A technology for injection molding equipment and brush handles, which is applied in the field of double-stage glue-injection brush handle injection molding equipment, which can solve problems such as lower product quality, mixed plastic colors, and inability to remove burrs, and achieve the effect of avoiding swinging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

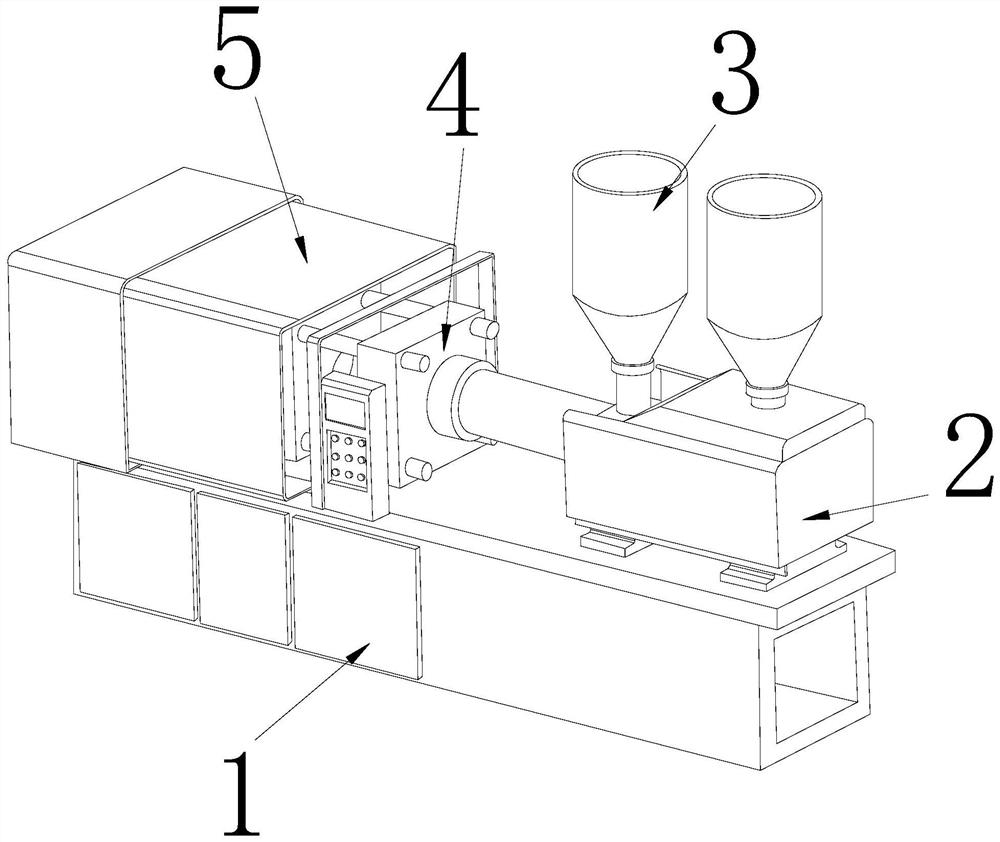

[0028] Such as Figure 1-Figure 6 As shown, the present invention provides a double-stage glue injection type brush handle injection molding equipment, the structure of which includes a machine base 1, a melting bin 2, a feeding bin 3, a pressing block 4, and a molding device 5. The melting bin 2 The bottom bolt is connected to the right side of the upper end of the machine base 1, the bottom end of the feeding bin 3 is embedded and connected to the upper end of the plastic melting bin 2, and the left side of the pressing block 4 is snapped and connected to the right side of the molding device 5 , the bottom end of the molding device 5 is fitted and connected to the upper left surface of the machine base 1 .

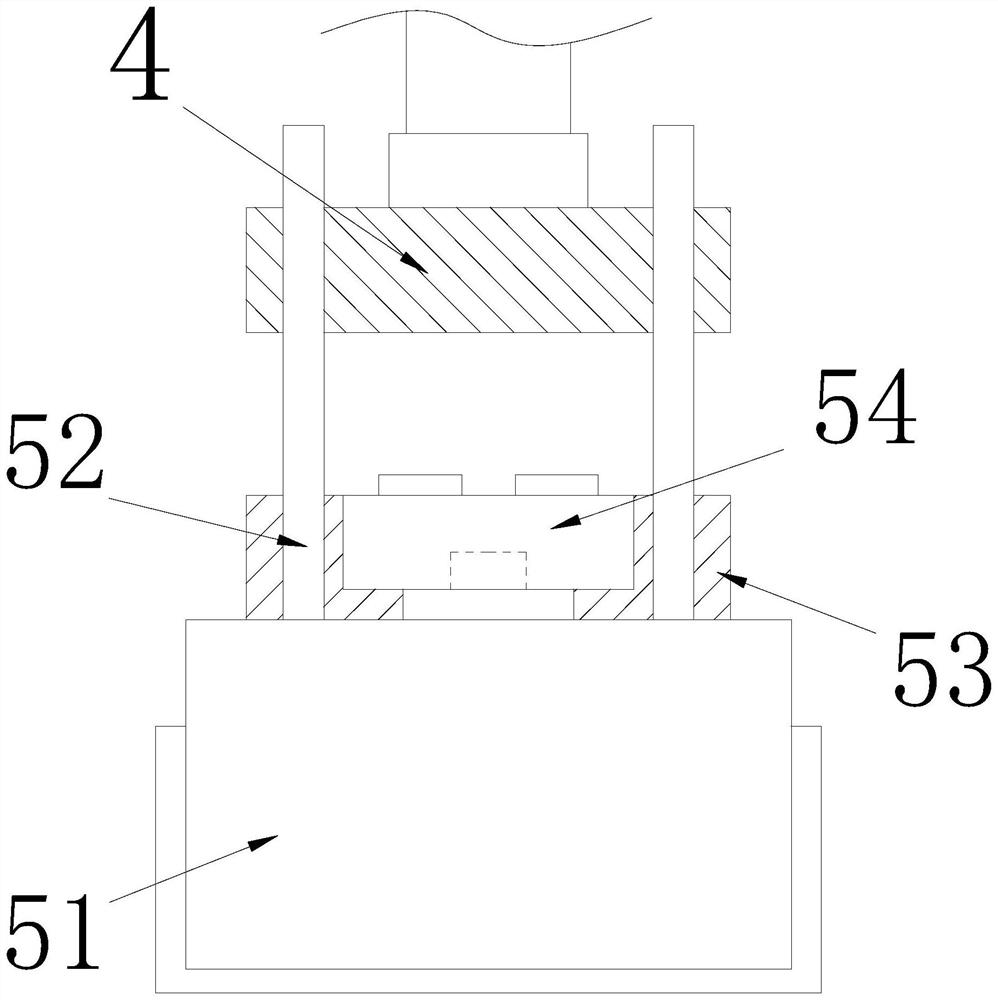

[0029] The molding device 5 includes a hydraulic seat 51, a lifting rod 52, a fixed seat 53, and a forming device 54. The outer periphery of the lower end of the lifting rod 52 is transitionally fitted inside the hydraulic seat 51, and the inner wall of the outer edge of...

Embodiment 2

[0037] Such as Figure 7-Figure 8 Shown:

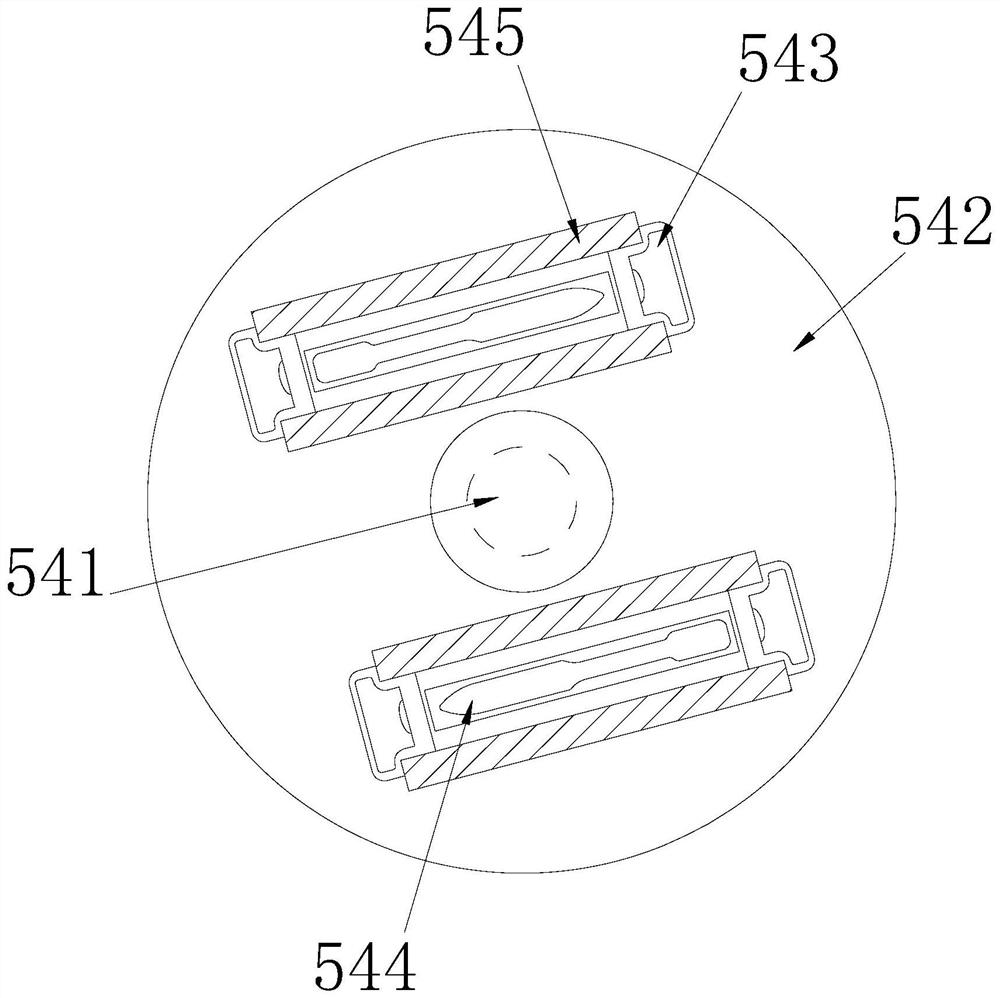

[0038] Wherein, the clamping block a54 includes a fitting piece b1, a block body b2, an elastic piece b3, and a breaking mechanism b4. On both sides of the upper surface of the body b2, the lower end of the breaking mechanism b4 is embedded and connected to the upper surface of the shrapnel b3. The shrapnel b3 is a semi-hollow arc-shaped sheet structure, which makes the two sides of the upper end break after being pressed. Mechanism b4 can be squeezed inward correctly.

[0039] Wherein, the breaking mechanism b4 includes a fixed column b41, a connecting block b42, a contact b43, a connecting shaft b44, and a cut-off piece b45. Connected to the center of the upper end of the connecting block b42, the connecting shaft b44 is fitted and connected to the inner edge of the side edge of the connecting block b42, the cut-off piece b45 is movably connected to the center of the front end of the connecting shaft b44, and the cut-off piece b45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com