Wearing method of clamping buckle sponge gasket

A buckle and sponge technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low wearing pass rate, low artificial wearing efficiency, and high labor intensity of artificial wearing sponge gaskets, so as to improve wearing efficiency, Reduce manual labor intensity and avoid hand injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

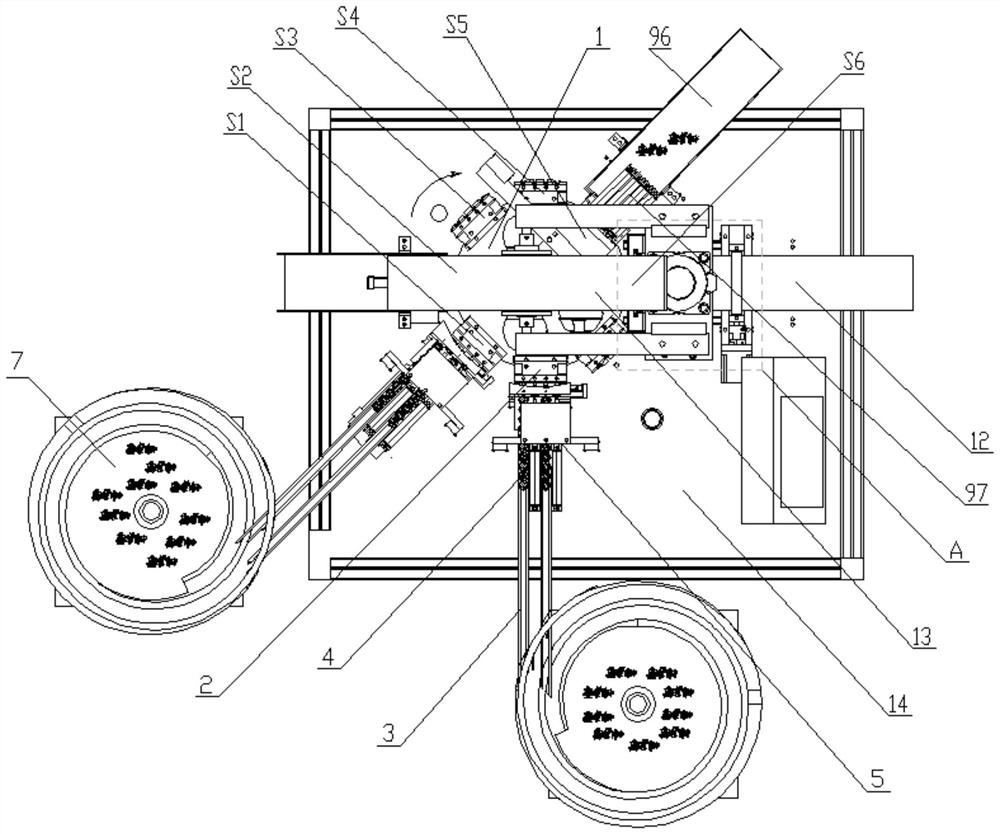

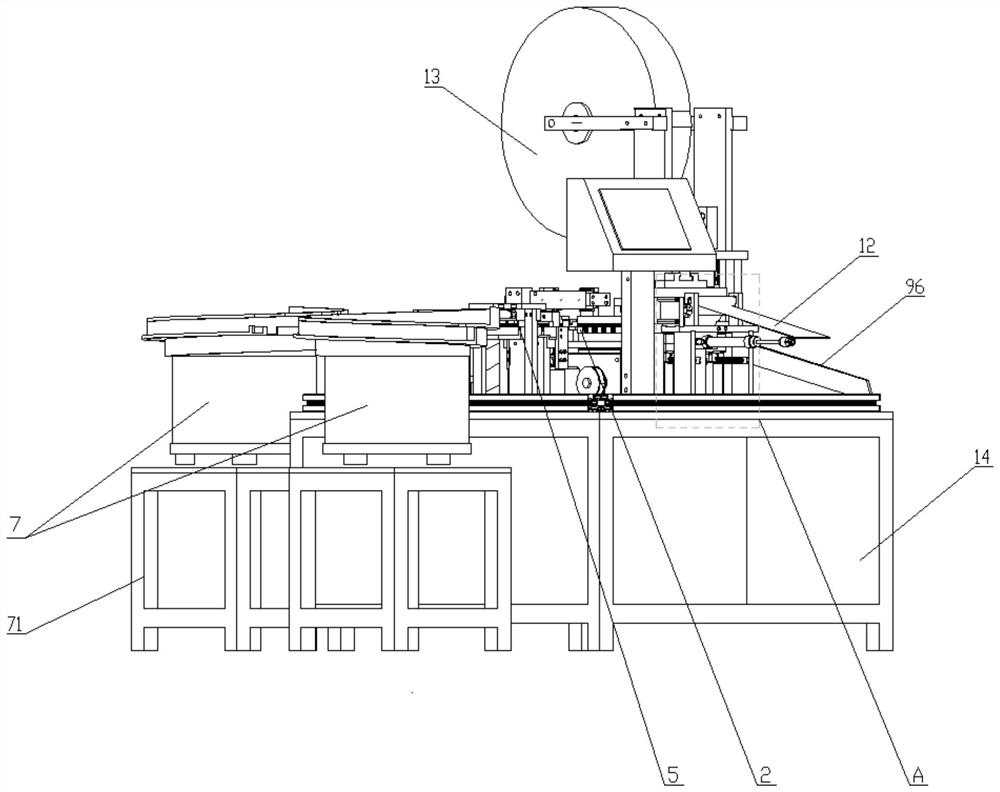

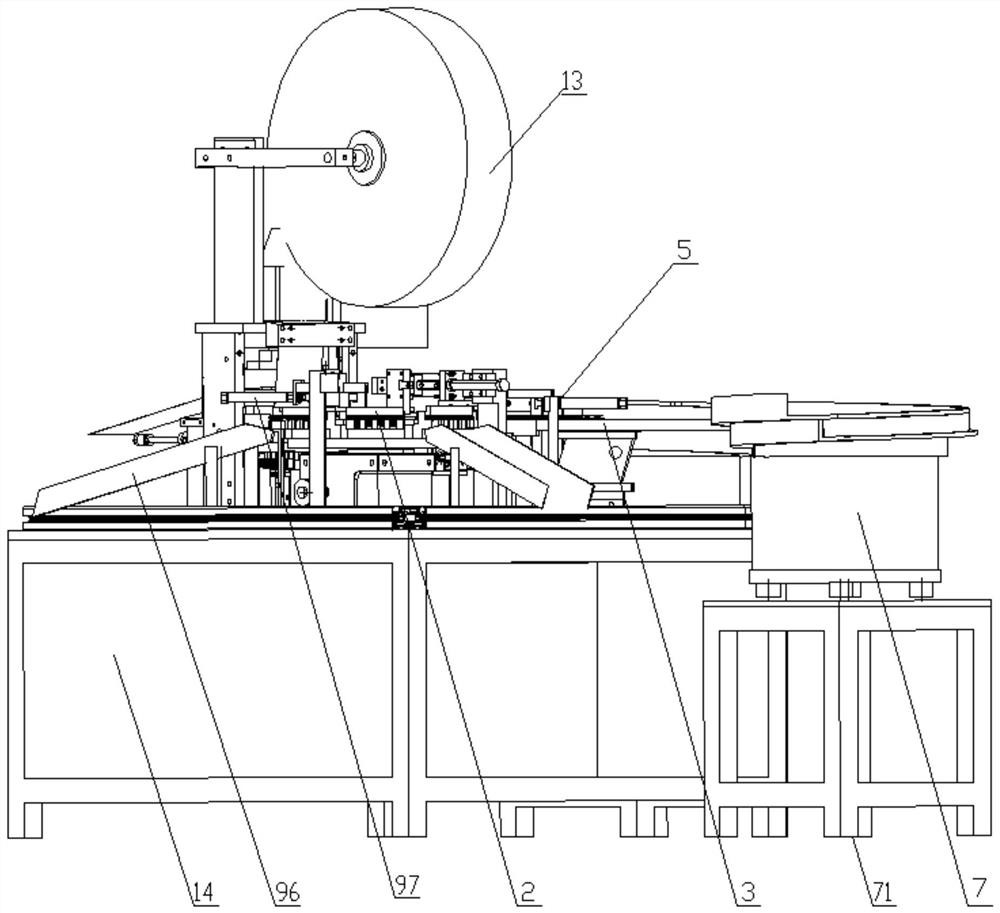

[0037] This embodiment focuses on the detailed introduction of the equipment used in the wearing method of the buckle sponge washer of the present invention.

[0038] see Figure 1 to Figure 13 , a snap-on sponge pad wearable device, the wearable device is set on the control cabinet 14, including: a turntable 1, a power system 58 for driving the turntable 1 to rotate, arranged on the edge of the turntable 1 and capable of rotating with the turntable (the Disk rotation refers to the buckle carrying part 2 which rotates synchronously with the turntable); the feeding mechanism, when the buckle carrying part 2 rotates with the disk to the end of the feeding track 3 of the feeding mechanism, the buckle is sent to the buckle carrying part 2 On; the punching mechanism for punching the sponge gasket 70; the wearing mechanism, when the buckle carrying part 2 rotates with the disk to the top of the top material part one 88 of the wearing mechanism, the punched sponge gasket will be punc...

Embodiment 2

[0060] This embodiment focuses on the introduction of the wearing method of the buckle sponge washer of the present invention.

[0061] A kind of wearing method of buckle sponge washer, see Figure 1 to Figure 13 , using the buckle sponge pad wearing device in Example 1, the steps are as follows,

[0062] Step 1: Use the vibrating material tray 7 to continuously buckle the feeding track 3, and make the buckles 4 on the feeding track 3 close to each other in a row, and realize the forward movement of the buckles 4 through the extrusion force of the adjacent buckles 4;

[0063] Step 2: Use the pushing mechanism 5 to push the buckle 4 at the end of the feeding track 3 to the buckle carrying part 2 on the edge of the turntable 1, and make the buckle 42 hang in the limit gap 21 of the buckle carrying part 2;

[0064] Step 3: Rotate the turntable 1, so that the buckle carrying part 2 and the buckle 42 carried by it rotate with the disk to directly above the top material part 1 88 of ...

Embodiment 3

[0071] A kind of wearing method of buckle sponge washer, see Figure 1 to Figure 13 , using the buckle sponge pad wearing device in Example 1, the steps are as follows,

[0072] Step 1: Use the vibrating material tray 7 to continuously buckle the feeding track 3, and make the buckles 4 on the feeding track 3 close to each other in a row, and realize the forward movement of the buckles 4 through the extrusion force of the adjacent buckles 4;

[0073] Step 2: Use the pushing mechanism 5 to push the buckle 4 at the end of the feeding track 3 to the buckle carrying part 2 on the edge of the turntable 1, and make the buckle 42 hang in the limit gap 21 of the buckle carrying part 2;

[0074] Step 3: Rotate the turntable 1, so that the buckle carrying part 2 and the buckle 42 carried by it rotate with the disk to directly above the top material part 1 88 of the sponge washer wearing mechanism;

[0075] Step 4: Start the wearing mechanism of the sponge washer, and set the sponge wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com