Breeding feed premixing equipment

A pre-mixing and feed technology, applied in the field of cattle and sheep breeding, can solve the problems of inconvenient feeding, complex structure, high space layout requirements, etc., and achieve the effect of simple structure, convenient centralized management, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are readily understood, and the invention is further illustrated in conjunction with the accompanying drawings and examples.

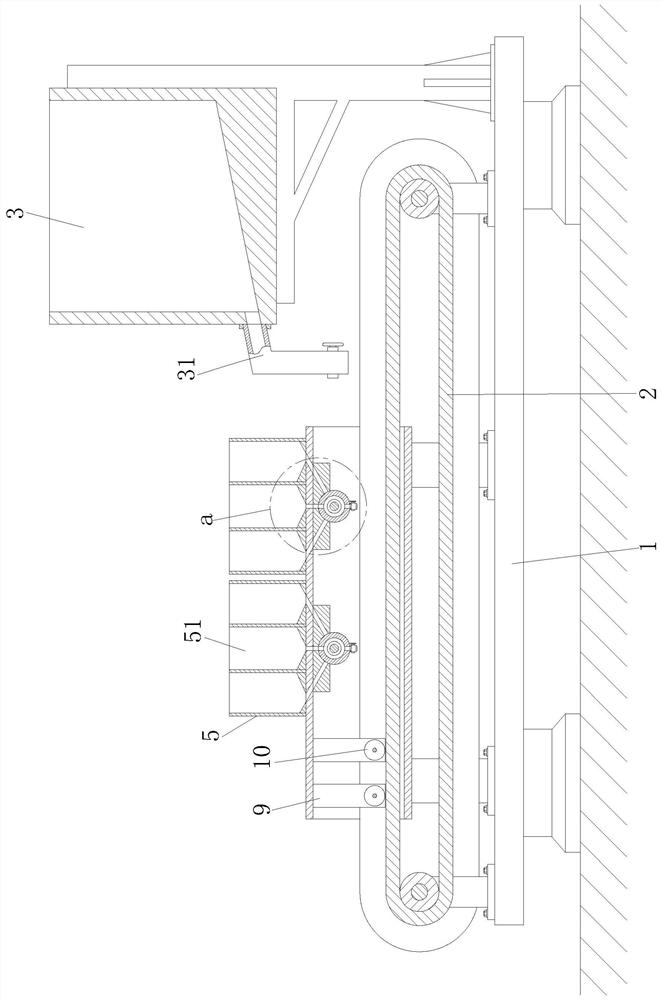

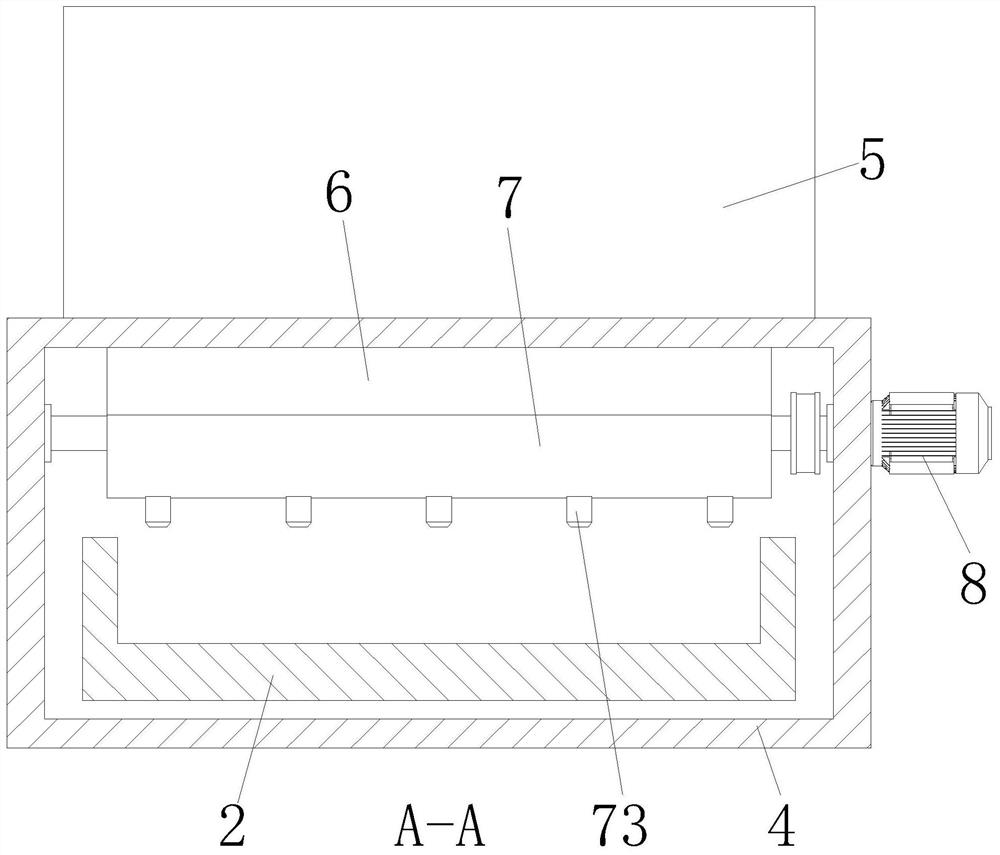

[0022] Such as Figure 1 to 5 As shown, a cultured feed premixing device includes a chassis platform, further comprising a base feed mechanism, a nutrient feed mechanism, a micro-element feeding mechanism, a multi-mixing mechanism, a nutrient feed mechanism, a micro-element feed mechanism, a premixing mechanism The chassis platform is also provided in the left-right direction and sequentially receives the binder, nutrients, trace elements from the right direction, and is fully premixed by the pre-mixing mechanism.

[0023] As a further improvement of the present invention, the base feed mechanism includes a base box 3 disposed on the chassis platform 1, and a base discharge opening 31 with a control valve is provided on the lower left side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com