Fruit kernel removing and cleaning equipment

A technology for cleaning equipment and fruits, applied in fruit de-pitting devices, food science, applications, etc., can solve problems such as arm soreness, time-consuming and laborious, and achieve the effect of avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

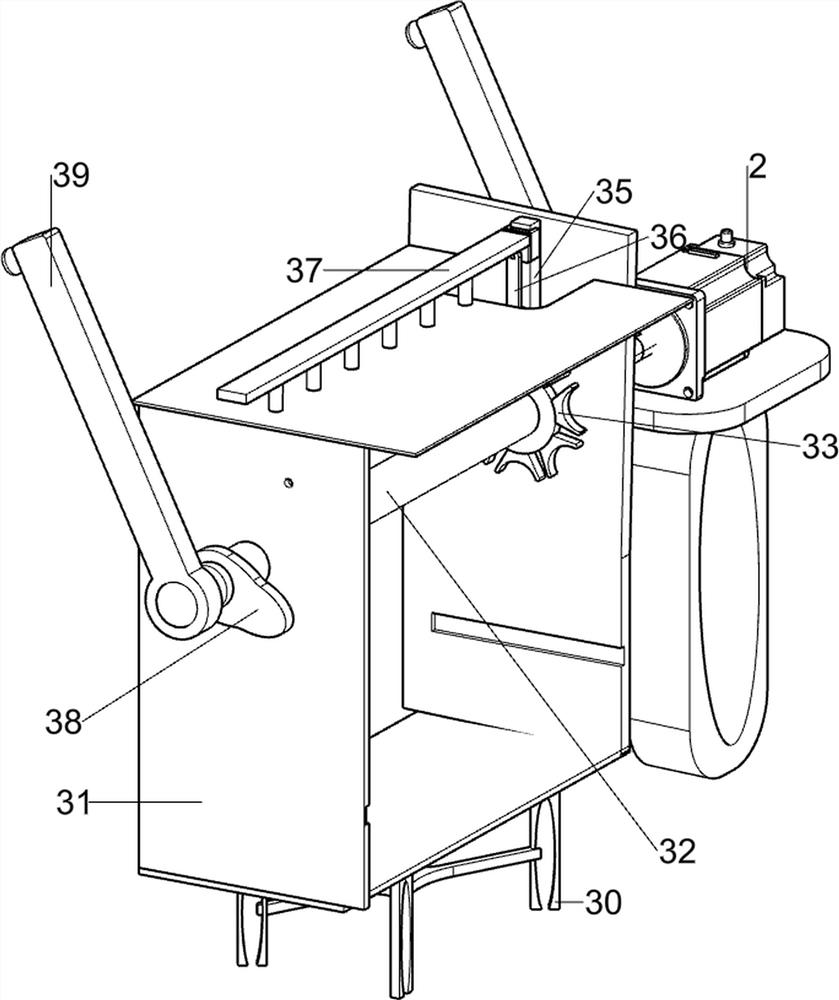

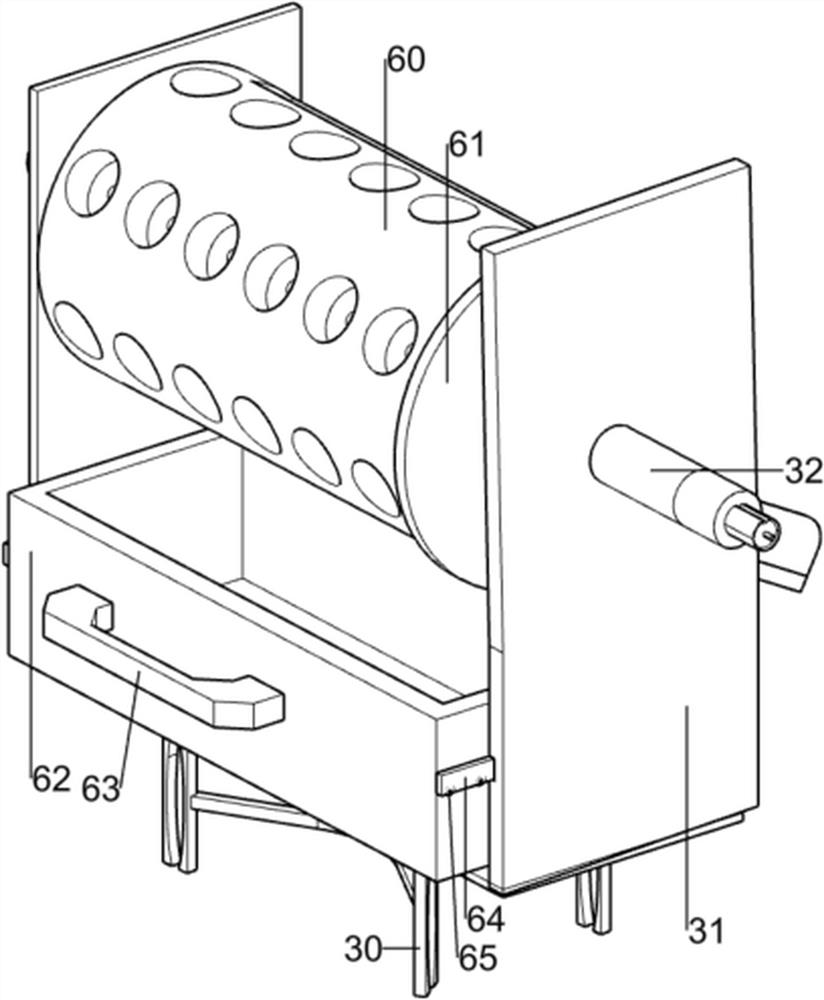

[0070] A kind of fruit pitting cleaning equipment, such as figure 1 , figure 2 , image 3 with Image 6 As shown, it includes a bottom plate 1, a servo motor 2, a coring mechanism 3 and a coring mechanism 6, a servo motor 2 is provided on the left rear side of the bottom plate 1, and a coring mechanism 3 is connected between the output shaft of the servo motor 2 and the bottom plate 1. The denucleating mechanism 3 is connected with a denucleating mechanism 6 .

[0071]The coring mechanism 3 includes a support chassis 30, a first baffle plate 31, a first rotating shaft 32, a Geneva rotating disc 33, a dial 34, a first slide rail 35, a first crank 36, a coring device 37, a second crank 38 and toggle plate 39, base plate 1 rear portion is provided with support chassis 30, and support chassis 30 is provided with first baffle plate 31, and first baffle plate 31 tops are rotationally connected with first rotating shaft 32, and first rotating shaft 32 The left side is connected ...

Embodiment 2

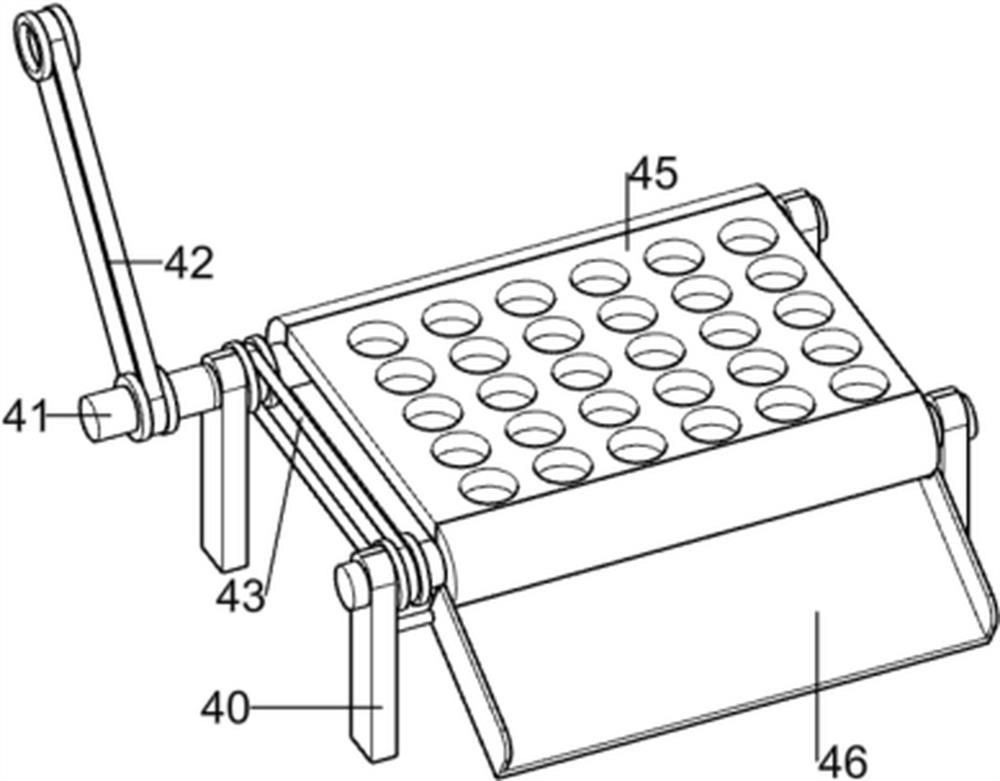

[0075] On the basis of Example 1, such as Figure 4 , Figure 5 , Figure 7 , Figure 8 with Figure 9 As shown, the transmission mechanism 4 includes a first support plate 40, a second rotating shaft 41, a first rotation assembly 42, a second transmission assembly 43, a conveyor belt 45 and a slide plate 46, and four first support plates 40 are arranged on the front of the base plate 1. , the first support plates 40 on the same side in the horizontal direction are connected to the second rotating shaft 41 in a rotational manner, and the first rotating assembly 42 is connected between the left side of the second rotating shaft 41 on the rear side and the first rotating shaft 32, and the second rotating shaft 41 A second transmission assembly 43 is connected between the left sides, a conveyor belt 45 is connected between the second rotating shafts 41 , and a slide plate 46 is connected between the first support plates 40 on the front side.

[0076] The fruit after being pit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com