Warehouse safety monitoring and checking method and system based on robot

A robot and warehouse technology, applied in the field of intelligent equipment, can solve the problems of inconvenient inventory and blockage, and achieve the effect of avoiding wrong inspection, saving human resources, and facilitating on-site inspection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

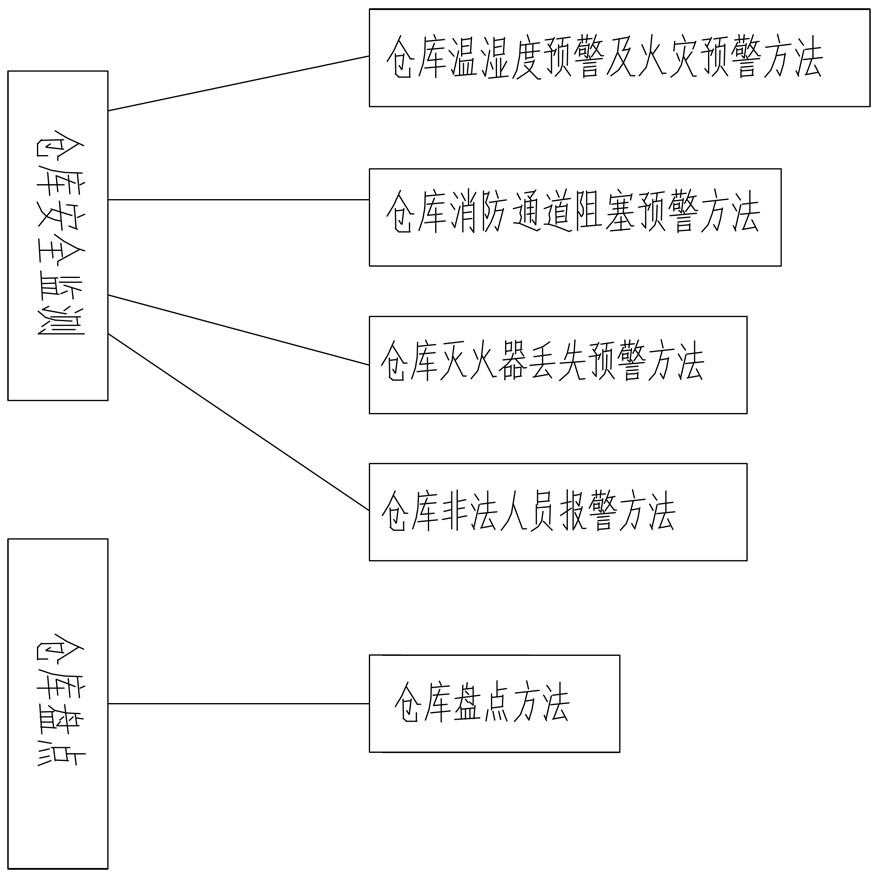

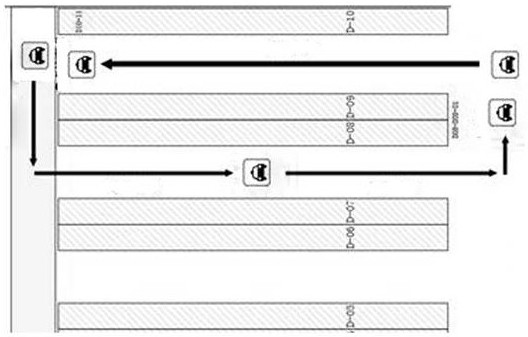

[0063] like figure 1 As shown, the first aspect of the embodiment of the present invention proposes a method for early warning of blockage of warehouse fire exits, including:

[0064] Step 1: Divide the warehouse into multiple areas through the fire exits, and move the robot to drive the visible light camera to take photos of the unblocked fire exits in the warehouse, and each fire exit needs to take the unblocked photos separately;

[0065] Place commonly used packing boxes, pallets and other materials in the warehouse on the fire exit, simulate the blockage of the fire exit and take pictures of the blockage, where each fire exit needs to take a separate photo of the blockage;

[0066] Step 2: combining the unblocked photos and blocked photos to generate a picture sample set, and training the image recognition neural network through the picture sample set;

[0067] Step 3: Set up a tracking car and a track in the warehouse, and the tracking car performs cyclic inspections ac...

Embodiment 2

[0074] The difference between the embodiments of the present invention and the above-mentioned embodiments is that the second aspect of the embodiments of the present invention proposes a robot-based warehouse inventory method, including;

[0075] Step 1: Calculate the quantity and location of the materials that need to be counted in the warehouse, and number the materials;

[0076] Set the UHF RFID tag on the material, and write the material number, position and other information into the UHF RFID tag through the RFID read-write device;

[0077] Put the material into the packaging box, and paste the corresponding UHF RFID label on the surface of the material packaging box, and ensure that each UHF RFID label is within the visible range;

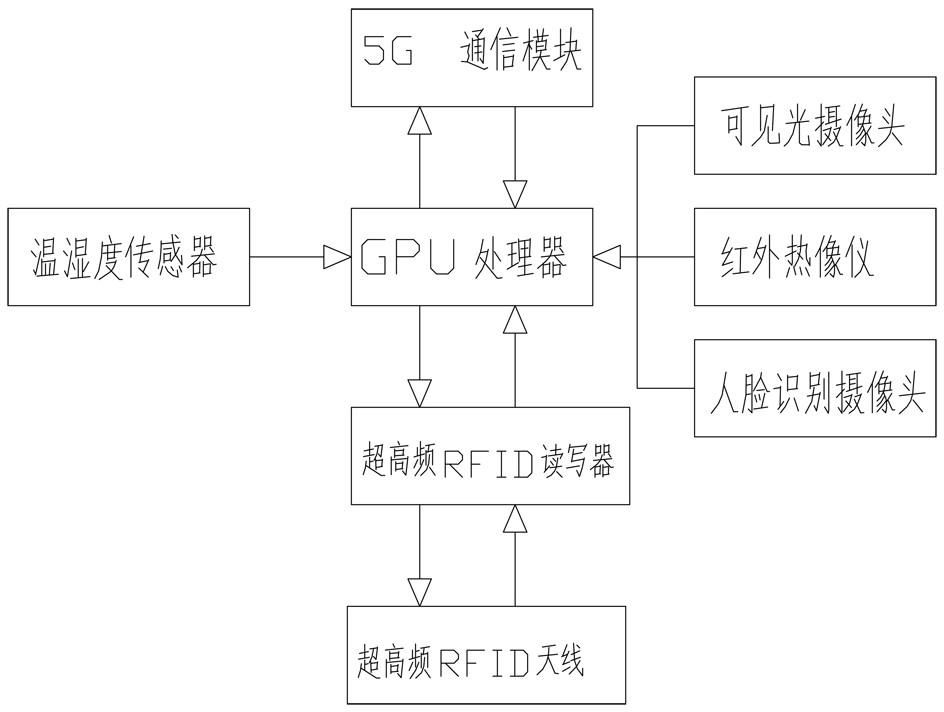

[0078] Step 2: The robot is equipped with a UHF RFID reader and four UHF RFID antennas;

[0079] The UHF RFID antenna includes a first RFID antenna on two sides and a second RFID antenna on two sides, the first RFID antenna and the second R...

Embodiment 3

[0088] The difference between the embodiment of the present invention and the above-mentioned embodiment is that the third aspect of the embodiment of the present invention proposes a robot-based warehouse temperature and humidity early warning and fire early warning method, including:

[0089] Step 1: The robot shoots thermal imaging video in real time through the infrared camera module and detects the surface temperature of the object in the video;

[0090] Step 2: Set fire warning threshold, humidity warning threshold and temperature warning threshold;

[0091] A tracking car and a track are set in the warehouse, and the tracking car moves according to the track, and the infrared thermal imager module captures the surface temperature of the object in the warehouse in real time, and judges whether the surface temperature of the object is greater than the fire warning threshold;

[0092] If it is greater than that, an automatic fire warning will be carried out, thermal imagin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com