Multi-end-face self-regulation starting steam turbine shaft end sealing method

A shaft end seal, steam turbine technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve problems such as leakage and seal failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

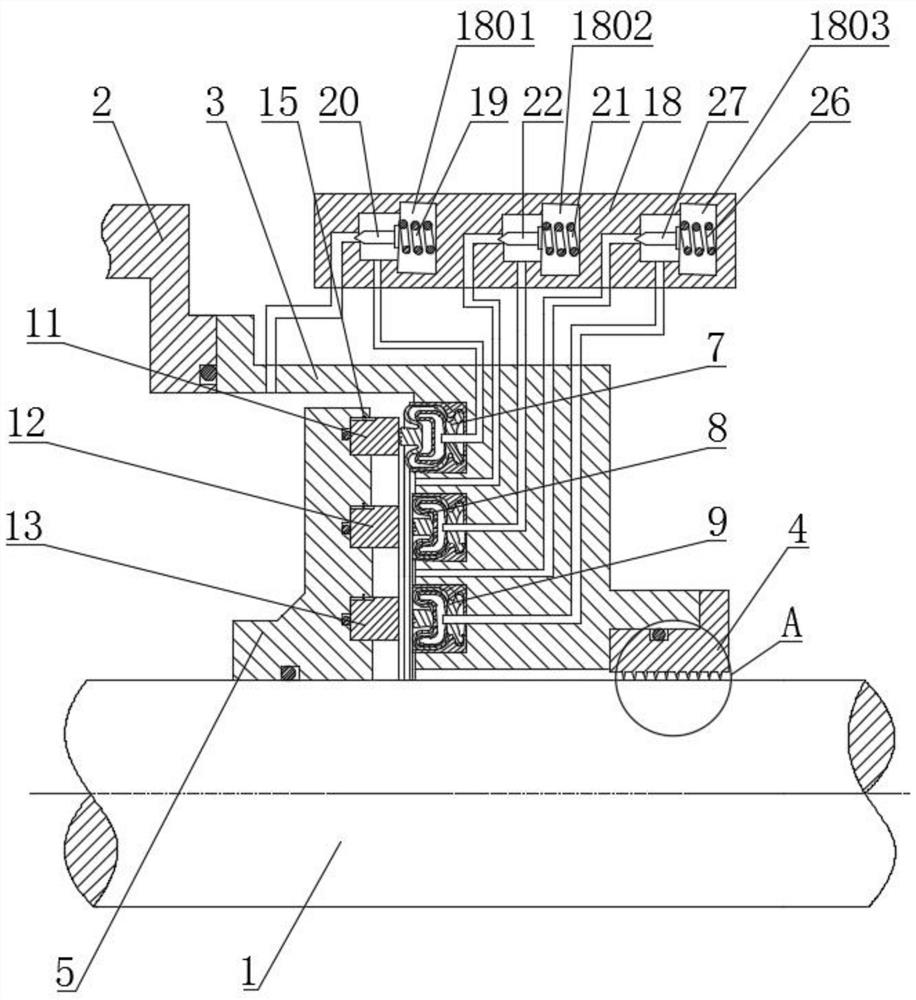

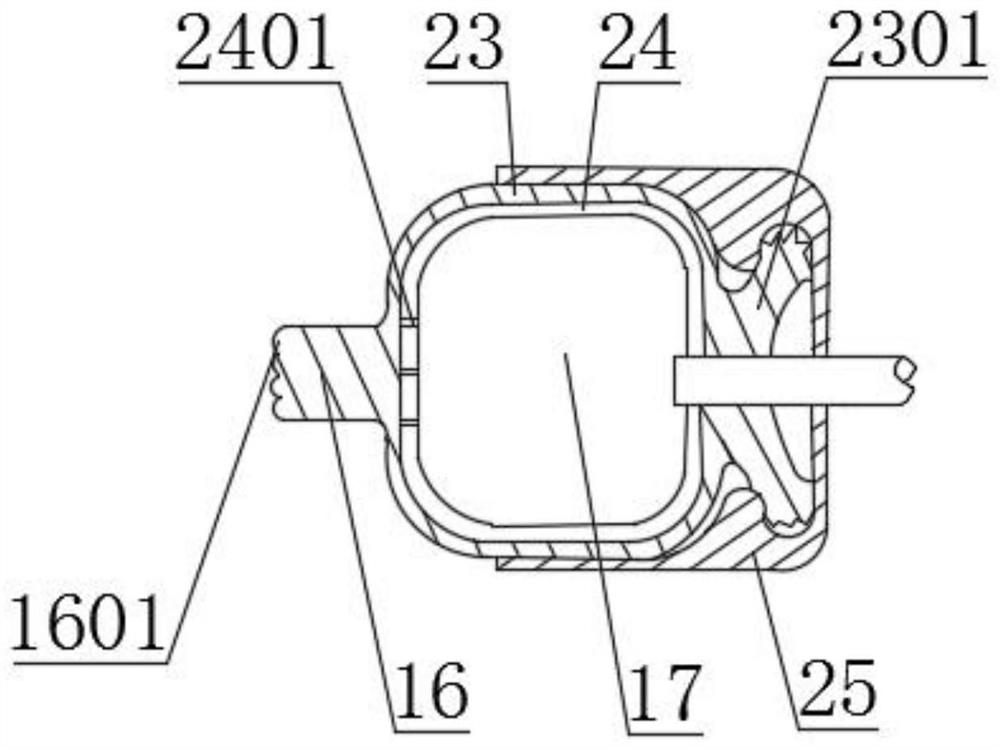

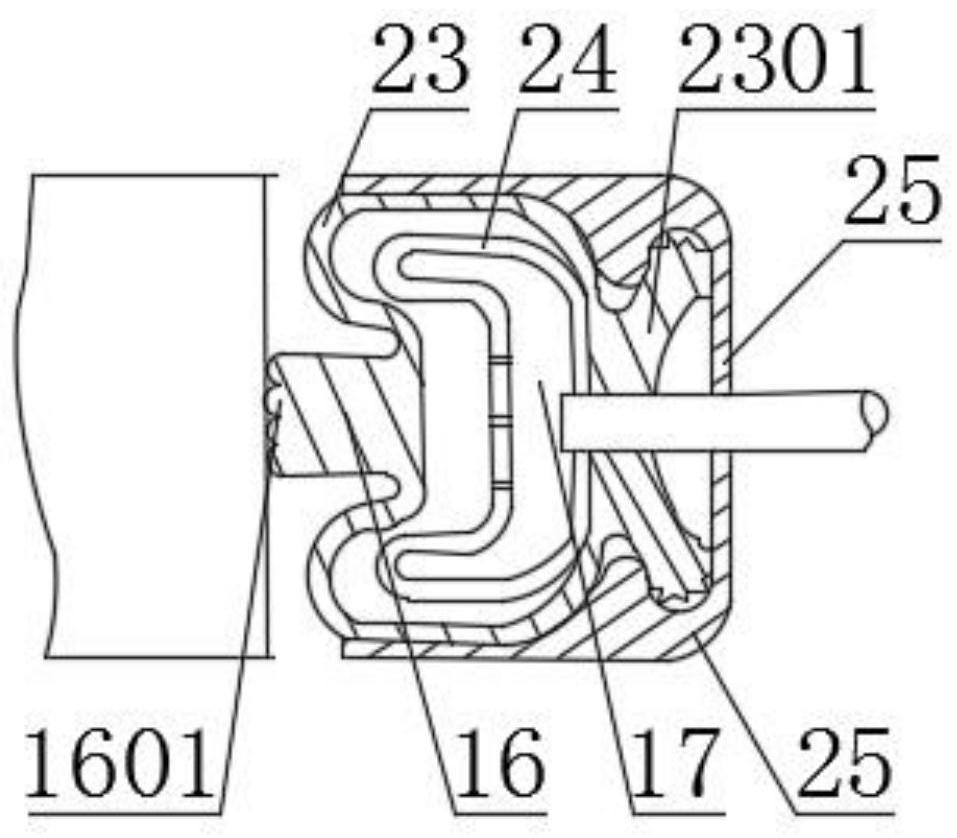

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] Such as Figure 1-5 As shown, a multi-face self-regulating shaft end sealing device for a steam turbine includes a casing, a rotating shaft 1 , a moving ring seat 5 and a pressure regulator 18 . A medium fluid cavity is provided between the casing and the rotating shaft 1, and for a steam turbine, the medium fluid in the medium fluid cavity is steam.

[0023] In order to facilitate the expression of the structural relationship of each component, the present invention distinguishes the left and right of the shaft end sealing device.

[0024] The casing includes a casing 2 , a static ring seat 3 and an end cover 4 connected in sequence. The left end surface of the stationary ring seat 3 is fixedly connected with the casing 2 , and the right end surface of the stationary ring seat 3 is fixedly connected with the end cover 4 . A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com