Mining robot under complex working conditions

A technology of complex working conditions and robots, applied in mining equipment, mining equipment, cutting machinery, etc., can solve problems such as single function, low mining efficiency, and easy coal seam collapse, so as to avoid safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

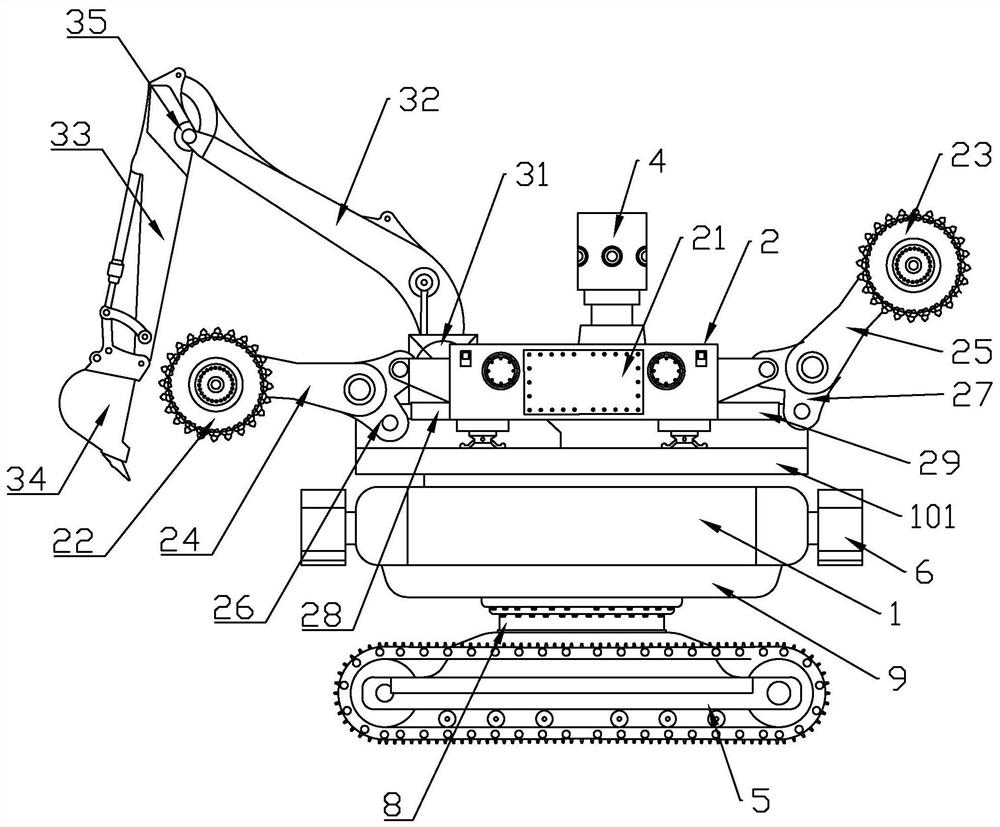

[0038] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

[0039] Such as figure 1 , figure 2 , image 3As shown, a mining robot under complex working conditions of the present invention includes a body 1 and a traveling mechanism. The interior of the body is provided with a PLC central control system, a mine explosion-proof battery and an external power supply interface. The PLC central control system includes A PLC central controller, a signal transmitting module and a signal receiving module, the signal transmitting module and the PLC central controller are respectively connected. Mining explosion-proof batteries are used for temporary power supply or temporary emergency power supply when mining robots enter the mining area.

[0040] The upper part of the body 1 is provided with a trapezoidal platform 101, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com