Automatic pushing-rolling control method for thin coal seam

A control method and technology for thin coal seams, which are applied in earth-moving drilling, mining equipment, mine roof supports, etc., and can solve the problems of no public tilt adjustment function and push-slip function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

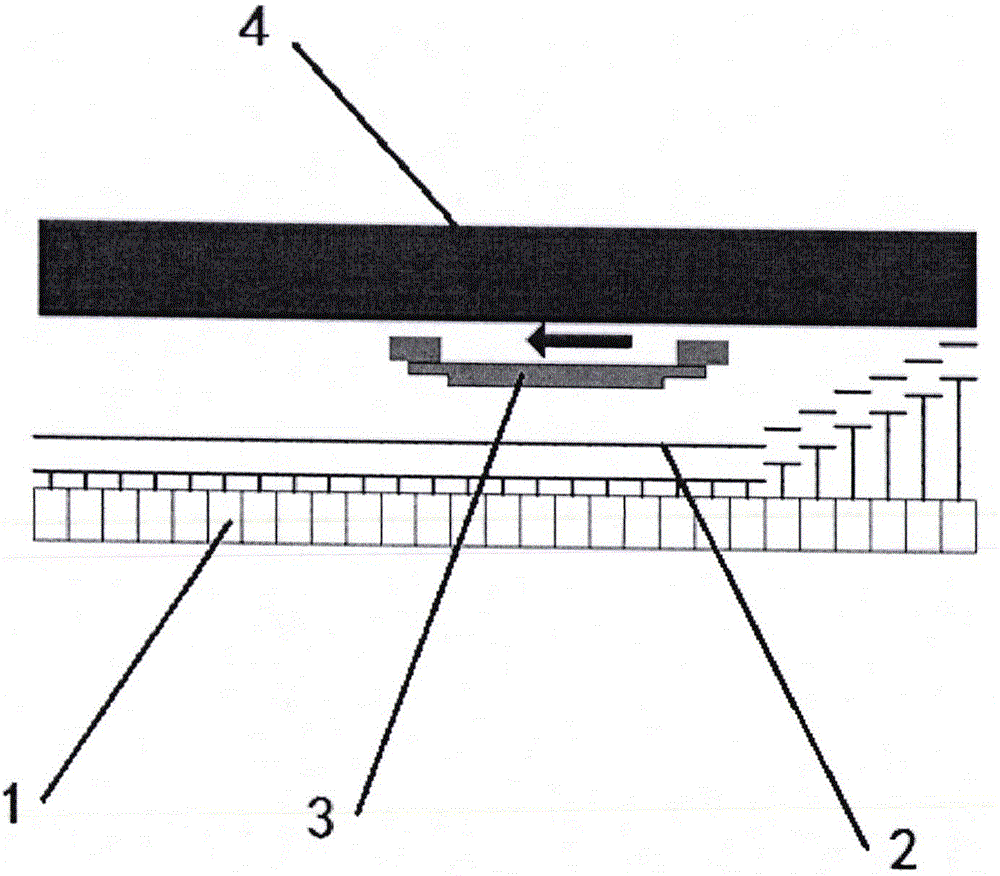

[0018] In a certain project, there are a total of 140 supports in front of the working face, which adopt two-way coal cutting. The slides are set between the working face and the hydraulic support. Each section of the slide is connected to the telescopic rod of the hydraulic support. There are 6 shearer body Brackets, 4 end brackets at both ends, 10 brackets in the feed section, feed distance 600mm, 10-function and 8-function main valves are installed at intervals on the working surface, and the tilting jack is equipped with a lock, that is, after the tilting jack is extended The tilt jack will only retract when the tilt jack is actively retracting. The 10-function and 8-function main valves of hydraulic supports on the working face are installed at intervals, and every 10 supports form a group, and a tilting jack is installed in a group.

[0019] At the end of the working face (including the nose, the tail, and the two feed sections), the automatic frame shifting and pushing ...

Embodiment 2

[0025] In the first embodiment, the push-off at the end can also be realized through the following steps.

[0026] No. 1 rack side end push

[0027] The coal shearer runs as far as the No. 3 rack. At this time, a group operation (manual operation) starting from the No. 16 rack triggers a pushing action with a group size of 8. The pushing starts from the No. 15 rack and ends with the No. 8 rack. The push and slide target strokes decrease in turn. Pushing this time is the process of releasing the cutting section.

[0028] When the coal shearer completes the cutting and exceeds the bracket number of No. 14, the group pushing operation is performed within the range of No. 1-14 racks, and the bracket pushing process is performed according to a single round of pushing process.

[0029] No. 140 rack side end push

[0030] The shearer goes as far as rack No. 140. At this time, a group operation (manual operation) starting from rack No. 126 triggers a pushing action with a group siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com