Atomizing, spraying and sizing device and method for digital printing pretreatment of high-pile fabric

A technology of atomization spraying and digital printing, which is applied in the direction of processing textile material equipment configuration, spraying/jetting textile material processing, etc., and can solve the problems of poor sizing permeability and poor penetration effect of high-pile fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

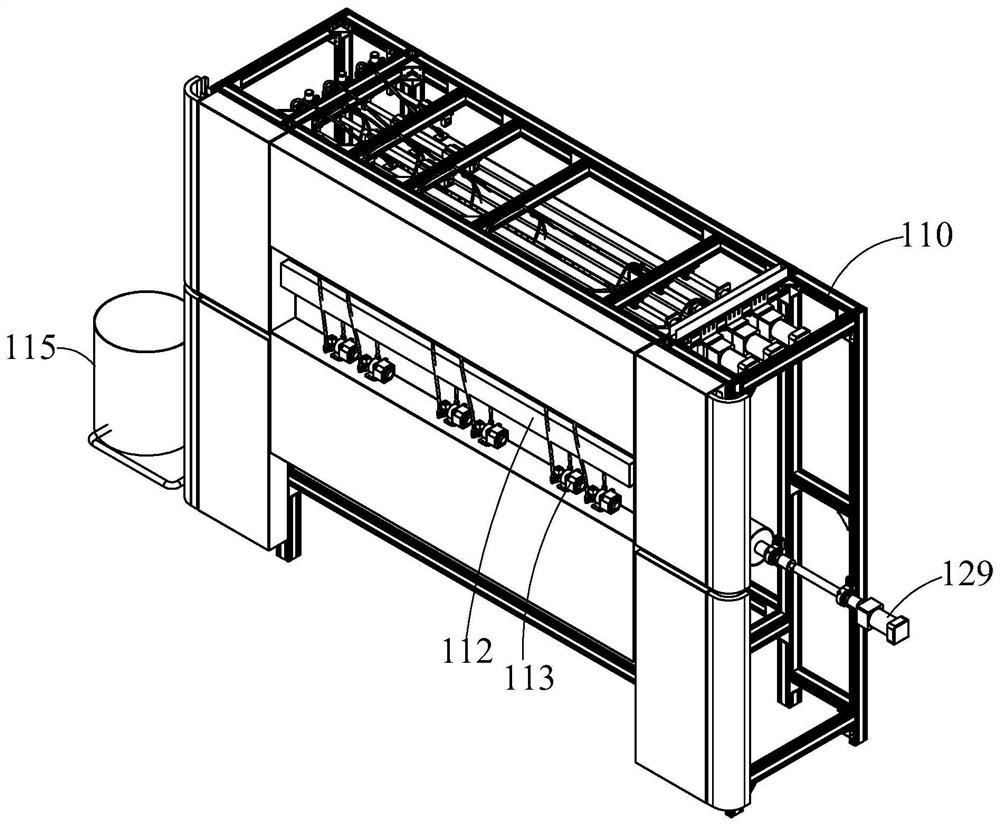

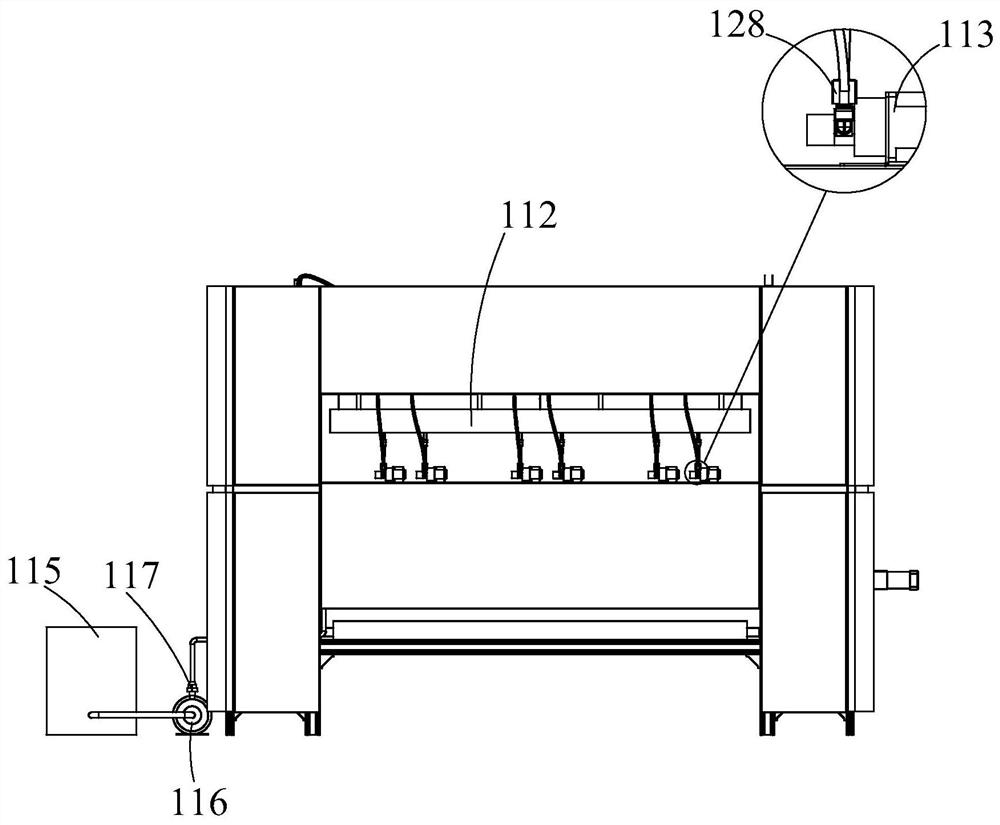

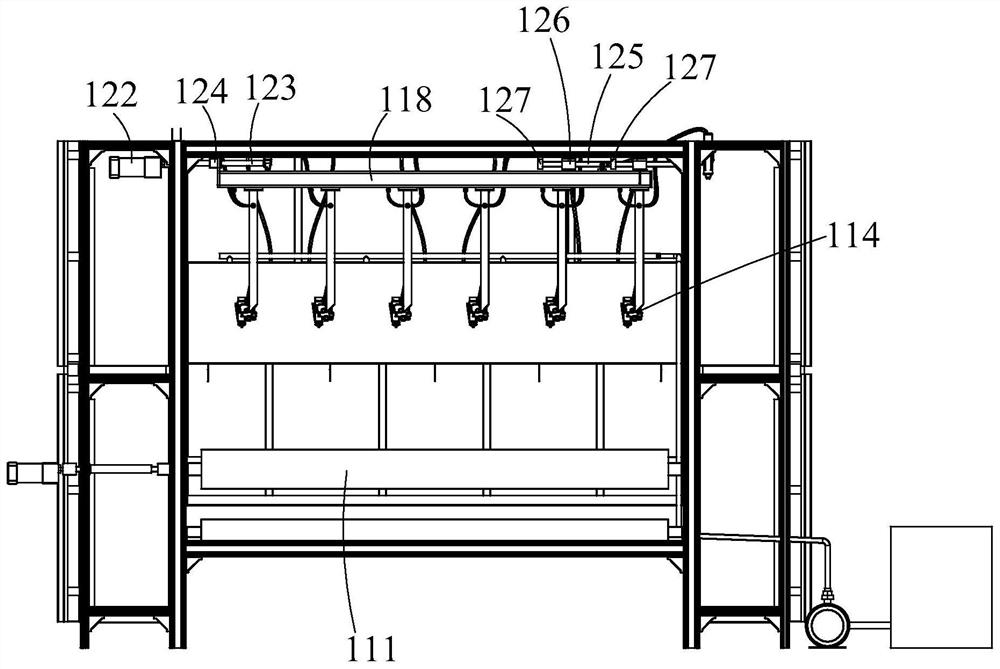

[0035] see Figure 1 to Figure 5 .

[0036] This embodiment discloses an atomizing spray sizing device for digital printing pretreatment of high-pile fabrics, and the high-pile fabrics are Raschel blankets as an example. The atomization spray sizing device comprises a frame 110, a fabric guide roller mechanism 111, an atomization spray mechanism, a raw pulp bucket 115 and a booster pump 116. The cloth guide roller mechanism 111 is installed on the frame 110, and it is driven by a motor 129 for guiding and conveying the fabric. The atomizing spraying mechanism is installed on the frame 110, and is located above the cloth guide roller mechanism 111, and it is used for spraying the white slurry on the fabric.

[0037] In this embodiment, the atomizing spray mechanism includes a slurry tank 112, a slurry supply pump 113 and three rows of atomizing nozzles 114, each row is provided with six atomizing nozzles 114, and the six atomizing nozzles 114 in the same row are installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com