One-way moisture-conducting fabric and preparation method and application thereof

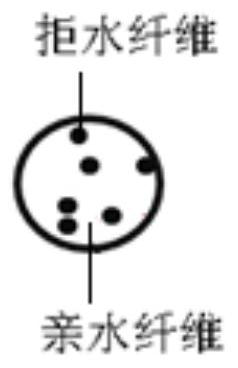

A unidirectional moisture-wicking, fabric technology, applied in the field of textile printing and dyeing, can solve the problem of inability to effectively use moisture-absorbing and sweat-wicking sports fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] This embodiment discloses a unidirectional moisture-guiding color-spun fabric and its yarn production method. The outer layer of the fabric is 40% cotton and 60% polyester moisture-absorbing and quick-drying color-spun yarn. Moisture-absorbing and quick-drying cotton-colored yarn is made by mixing 40% moisture-absorbing and quick-drying cotton and 60% polyester according to the requirements of color spinning, and then going through carding, drawing, roving, spun yarn, winding and other processes.

[0060] The following is the preparation process of moisture-absorbing and quick-drying cotton fiber:

[0061] Pre-treatment: scouring the cotton fiber in the pre-treatment aqueous solution, based on the total mass of the cotton fiber, adding 3wt% H 2 o 2 , 1wt% scouring agent and 0.8wt% sodium hydroxide were scoured at 100°C for 60 minutes; mixture;

[0062] Hot wash: hot wash at 80°C for 20 minutes;

[0063] For peracid deoxidation treatment, immerse in an aqueous soluti...

Embodiment 2

[0094] This embodiment discloses a pure cotton one-way moisture-guiding color-spun fabric and its yarn production method. The outer layer of the fabric is 100% moisture-absorbing and quick-drying cotton color-spun yarn. Moisture-absorbing and quick-drying cotton-colored yarn is made by mixing moisture-absorbing and quick-drying white cotton and moisture-absorbing and quick-drying colored cotton according to the requirements of color spinning, and then going through carding, drawing, roving, spun yarn, winding and other processes.

[0095] The following is the preparation process of moisture-absorbing and quick-drying cotton fiber:

[0096] Pre-treatment: scouring the cotton fiber in the pre-treatment aqueous solution, based on the total mass of the cotton fiber, adding 3wt% H 2 o 2 , 1wt% scouring agent and 0.8wt% sodium hydroxide were scoured at 100°C for 60 minutes; mixture;

[0097] Hot wash: hot wash at 80°C for 20 minutes;

[0098] For peracid deoxidation treatment, i...

Embodiment 3

[0130] This embodiment discloses a unidirectional moisture-guiding color-spun fabric and its yarn production method. The outer layer of the fabric is 100% moisture-absorbing and quick-drying color-spun yarn. Moisture-absorbing and quick-drying cotton yarn is produced by mixing 60wt% moisture-absorbing and quick-drying cotton with 40wt% ordinary cotton according to the requirements of color spinning, and then going through carding, drawing, roving, spinning, winding and other processes.

[0131] The following is the preparation process of moisture-absorbing and quick-drying cotton fiber:

[0132] Based on the total mass of cotton fiber, add 15wt% H 2 o 2 1.5wt% scouring agent and 3wt% caustic soda were scoured at 95°C for 55 minutes; the scouring agent was a mixture of fatty acid methyl ester polyoxyethylene ether and alkyl sodium sulfonate in a mass ratio of 1:2;

[0133] Hot wash at 90°C for 15 minutes;

[0134] For peracid deoxidation, immerse in an aqueous solution conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| one-way transfer index | aaaaa | aaaaa |

| one-way transfer index | aaaaa | aaaaa |

| one-way transfer index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com