Precipitation-free, low-water-absorption, halogen-free and flame-retardant reinforced nylon 66 as well as preparation method and application thereof

A low water absorption, nylon technology, used in the field of non-precipitation, low water absorption, halogen-free flame retardant reinforced nylon 66 and its preparation, which can solve the problems of increasing the migration of low molecular compounds such as flame retardants, and changing the size of parts.

Active Publication Date: 2021-06-08

长沙五犇新材料科技有限公司

View PDF12 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As a result, the size of the component changes; at the same time, the migration of water molecules in the PA66 resin greatly promotes the migration of l

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

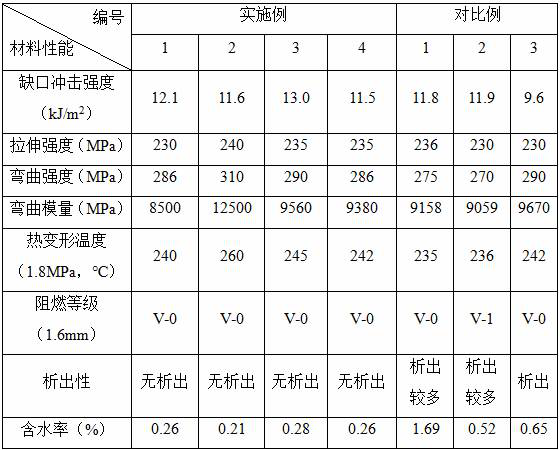

| Property | Measurement | Unit |

|---|---|---|

| Notched impact strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses precipitation-free, low-water-absorption, halogen-free and flame-retardant reinforced nylon 66 as well as a preparation method and application thereof. The reinforced nylon 66 comprises the following components: nylon 66 resin, a halogen-free flame retardant, a synergist, glass fibers, an anti-precipitation agent, a nucleating agent, a dispersing agent, a lubricating agent and an antioxidant. The preparation method comprises the following steps: adding the nylon 66 resin into a main material scale, adding the halogen-free flame retardant, the synergist, the anti-precipitation agent, the nucleating agent, the dispersant, the lubricant and the antioxidant into a mixer for mixing, adding an auxiliary material scale, adding the glass fibers into a side feeding metering scale, starting a double-screw extruder, sequentially starting a main material metering extruder and an auxiliary material metering extruder, performing discharging, starting a side feeding metering extruder, performing heating, melting, blending and extruding in the double-screw extruder, and performing cooling and granule cutting to obtain high-strength plastic. The reinforced nylon 66 has the advantages of high strength, high flame retardance, no precipitation, low water absorption, stable size, no toxicity and environment friendliness. The method is simple in process, low in cost and suitable for industrial production.

Description

technical field [0001] The invention relates to a flame-retardant reinforced nylon 66 and its preparation method and application, in particular to a non-precipitation, low water absorption and halogen-free flame-retardant reinforced nylon 66, its preparation method and its application. Background technique [0002] Flame retardant reinforced PA66 is widely used in electrical, electronic and electrical structural components due to its excellent mechanical properties and heat resistance. In the last century, brominated flame retardants were used in the manufacture of flame-retardant reinforced PPA66 composite materials. Brominated flame retardants have been widely used because of their good flame-retardant effect, low dosage, and small impact on the mechanical properties of composite materials. Because brominated flame retardants will produce dioxins during combustion, causing serious pollution to the environment, the European Union issued environmental regulations at the begi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L77/06C08L83/04C08L23/06C08K7/14C08K3/32C08K5/20C08K5/5313C08K13/04

CPCC08L77/06C08K2003/323C08L2201/22C08L2201/02C08L2201/08C08L2205/035C08L2205/025C08L83/04C08L23/06C08K7/14C08K3/32C08K5/20C08K5/5313C08K13/04

Inventor 邓凯桓陈如意

Owner 长沙五犇新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com