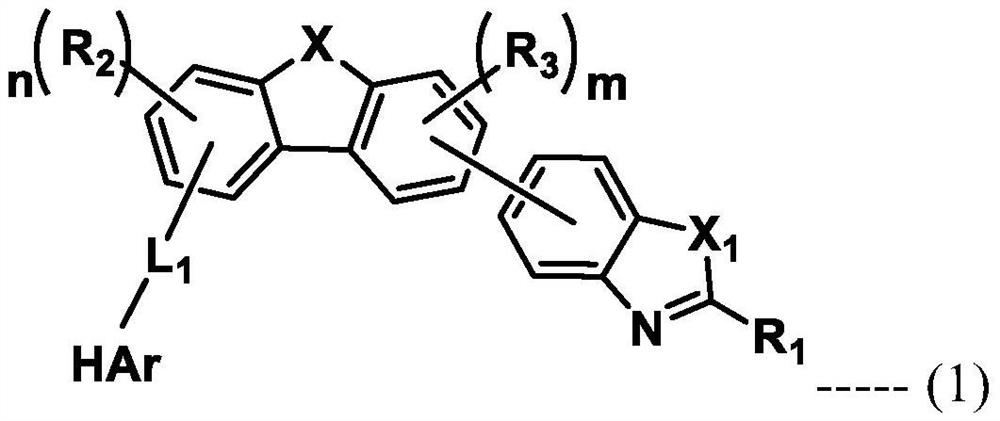

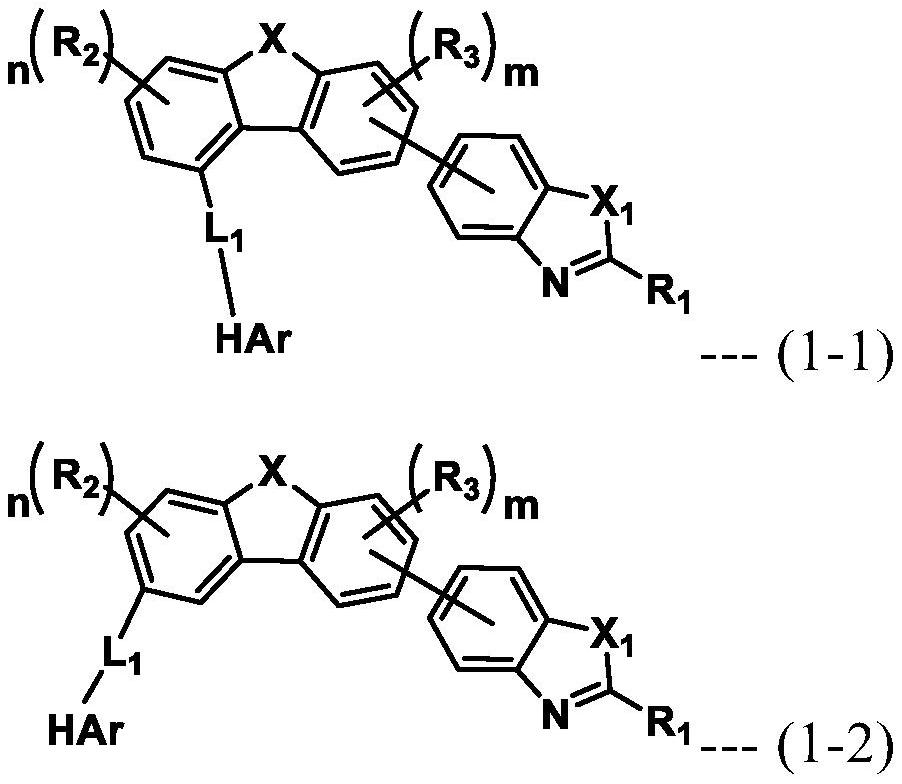

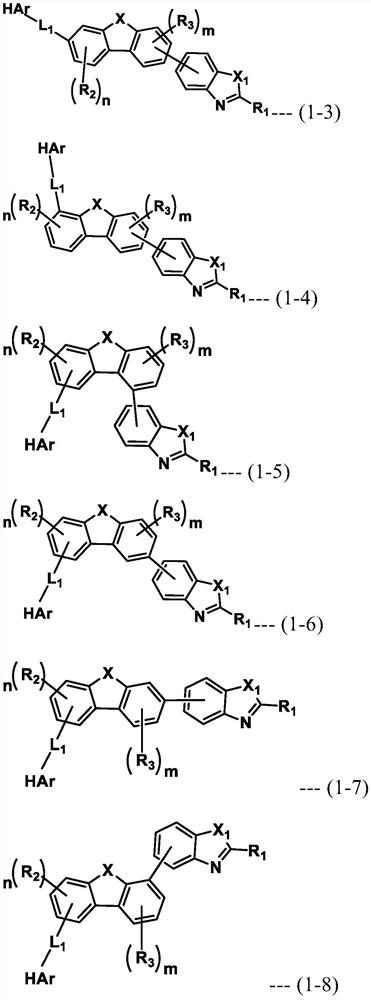

Organic electroluminescent compound and organic electroluminescent device comprising the same

A compound and luminescent technology, applied in organic chemistry, luminescent materials, organic semiconductor devices, etc., can solve the problems of reduced device life, no specific disclosure of organic electroluminescent compounds, poor thermal stability, etc., and achieve the effect of improving the operating voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0111] Example 1: Preparation of Compound A-1

[0112]

[0113] 1) Synthesis of compound 2

[0114] In a reaction vessel, 7.3 g of compound 1 (18.2 mmol), 3.9 g of N-bromosuccinimide (NBS) (21.8 mmol), 180 mL of sulfuric acid, and 180 mL of acetic acid were added, and the mixture was stirred at room temperature for 18 hours. After the reaction was completed, water was added thereto for dilution. The resulting solid was obtained and then dried. The residue was purified by column chromatography to obtain 5.7 g of Compound 2 (yield: 66%).

[0115] 2) Synthesis of Compound 4

[0116] In a reaction vessel, 10 g of compound 3 (36.4 mmol), 11 g of bis(pinacolate) diboron (43.6 mmol), 0.32 g of bis(triphenylphosphine)palladium(II) dichloride (1.82 mmol), 10 g of potassium acetate (109.2 mmol), and 180 mL of 1,4-dioxane, and the mixture was stirred at 130° C. for 2 hours. After the reaction was completed, the reaction mixture was cooled to room temperature and the organic ...

example 2

[0130] Device Example 2: Production of OLEDs Comprising Compounds According to the Disclosure as Second Host

[0131] OLEDs were produced in the same manner as in Device Example 1, except that the light-emitting layer was formed as follows: the first host and the second host shown in Table 2 below were introduced as hosts into two chambers of a vacuum vapor deposition apparatus, respectively, and Compound D-50 was introduced as a dopant into another chamber. Evaporating the two host materials at different rates of 2:1, and simultaneously evaporating the dopant material at different rates, depositing the dopant at a doping amount of 10 wt% based on the total amount of host and dopant, A light emitting layer having a thickness of 40 nm was thus formed on the second hole transport layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap