A horse riding linkage binding line

A binding line and linkage technology, which is applied in the field of horse-riding linkage binding line, can solve the problems that the innermost book page is easily damaged, the book page is detached from the iron wire nails, and the book page is poor in firmness, so as to increase the difficulty of falling off, easy to take, and improve the firmness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following is attached Figure 1-10 The application is described in further detail.

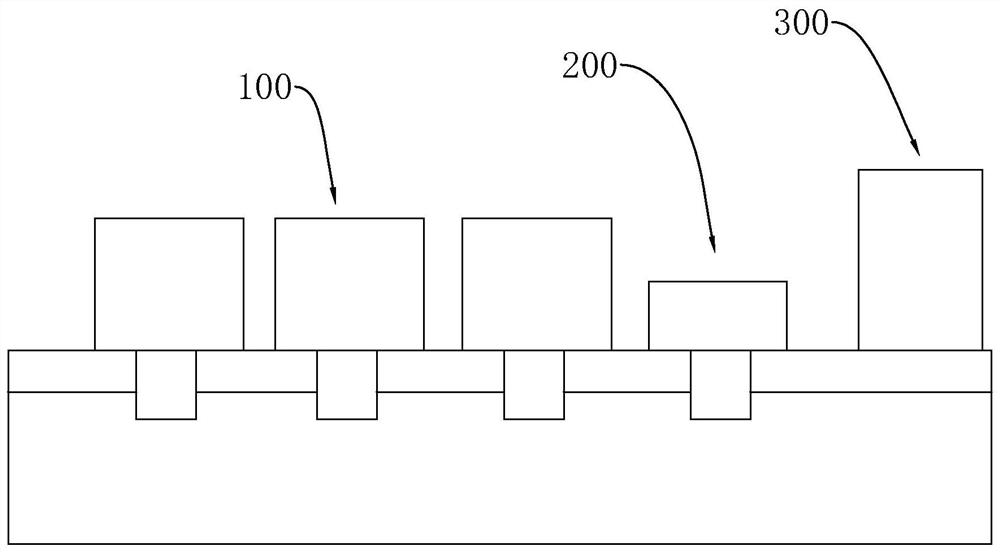

[0043] The embodiment of the present application discloses a horse-riding linkage binding thread. refer to figure 1 , including a page-joining unit 100, a stapler 200 and a shredder 300 connected in sequence. When in use, the pages 30 are automatically collated through the page-joining unit 100, and then the book pages 30 are stacked in order by the stapler 200. The book pages 30 together are bound, and finally the book pages 30 are cut by the shredder 300 , so as to complete the automatic binding of the book pages 30 .

[0044] Wherein, the paging unit 100 and the shredder 300 are existing equipment, and the specific structure can refer to the reference document mentioned in the background technology of the present application, and will not be repeated here.

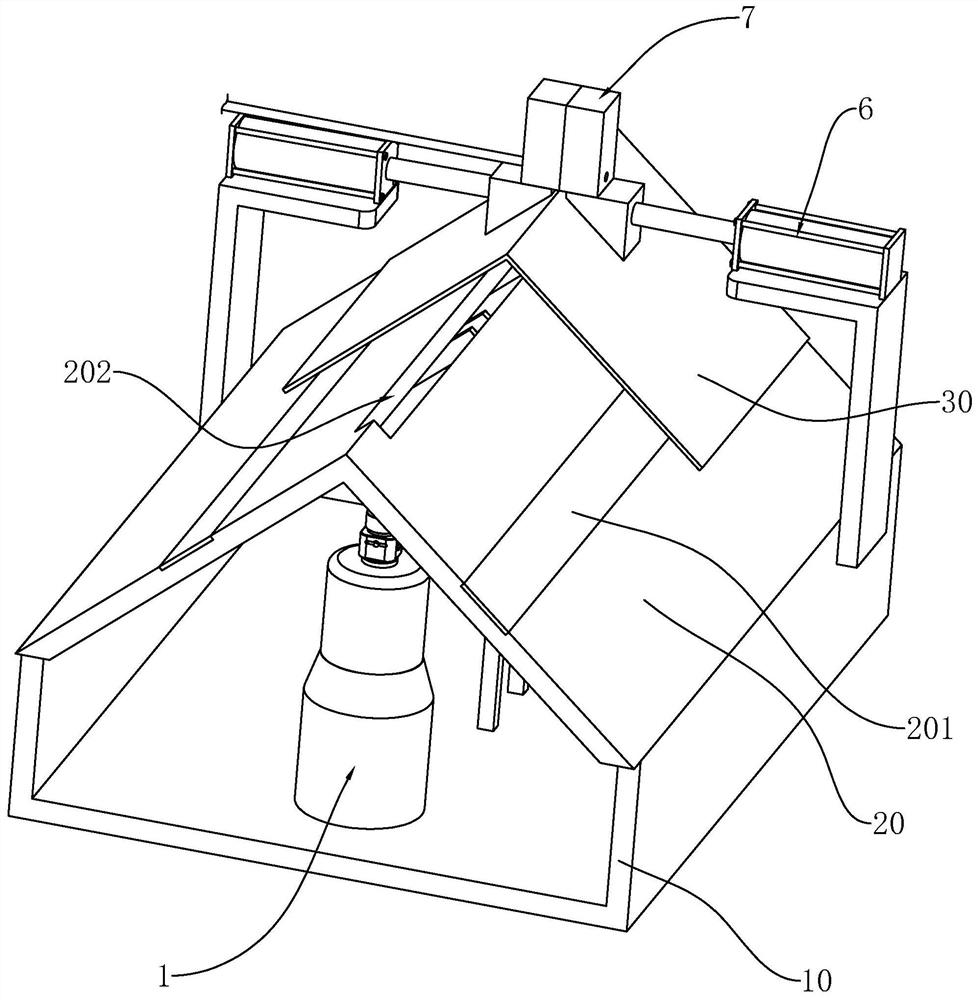

[0045] Such as figure 2 As shown, the stapler 200 includes a machine base 10 and a ridge-shaped worktable 20 arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com