Colored spun yarn primary color system construction method

A construction method and color spinning technology, applied in manufacturing computing systems, image data processing, instruments, etc., can solve the problem of inability to meet the diverse and personalized needs of users, affecting the cost and efficiency of color production and management of color spinning enterprises, design Problems such as inconvenience in finding teachers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] When the technical scheme of the present invention is specifically implemented, it can be operated by those skilled in the art using relevant data and computer software technology. In conjunction with the accompanying drawings, the specific description of the embodiments of the present invention is provided as follows.

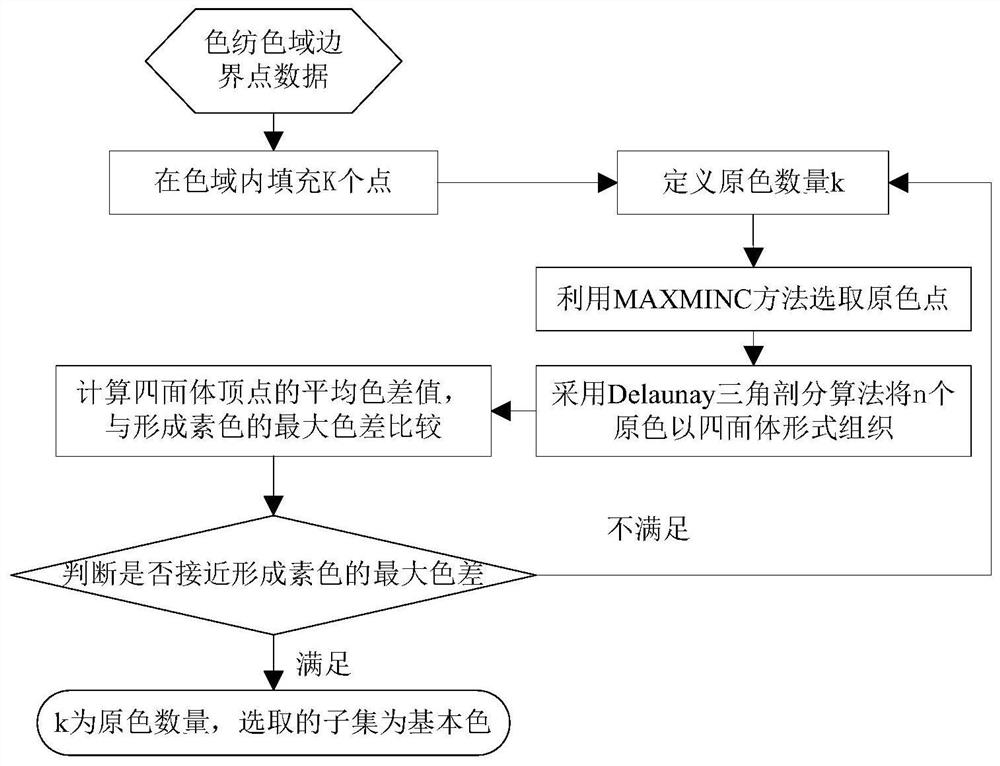

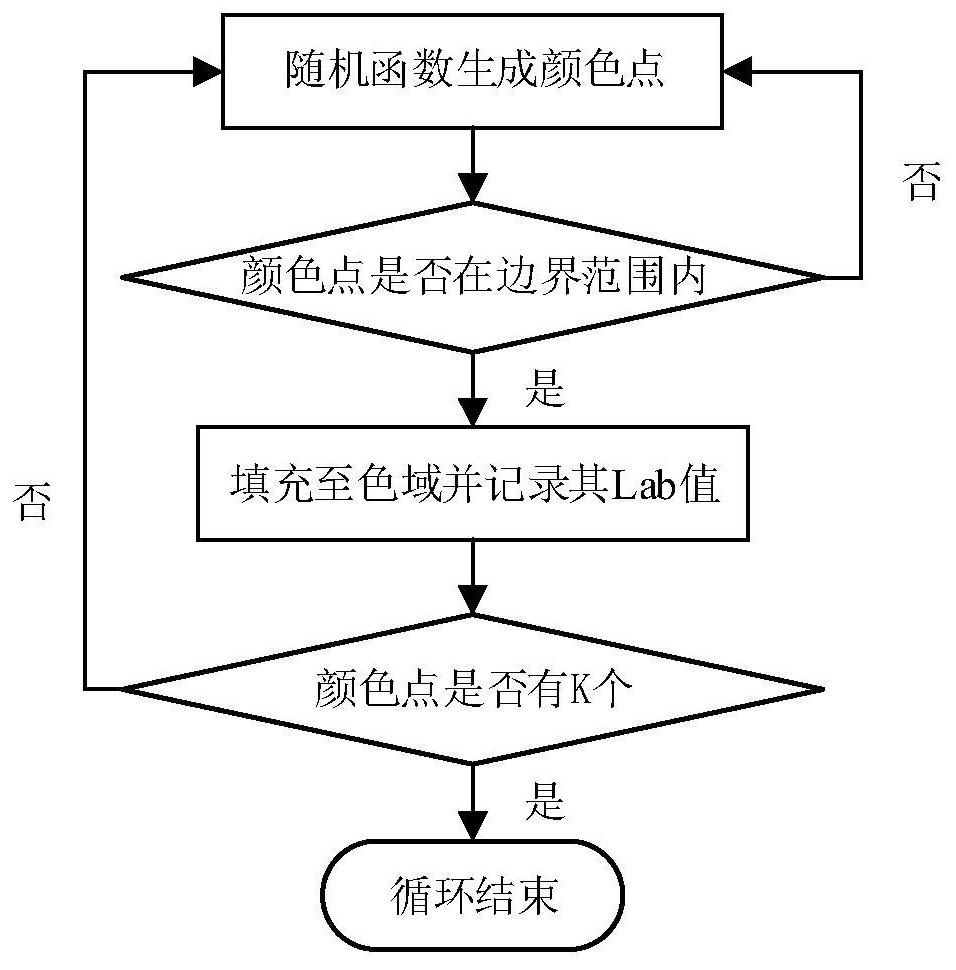

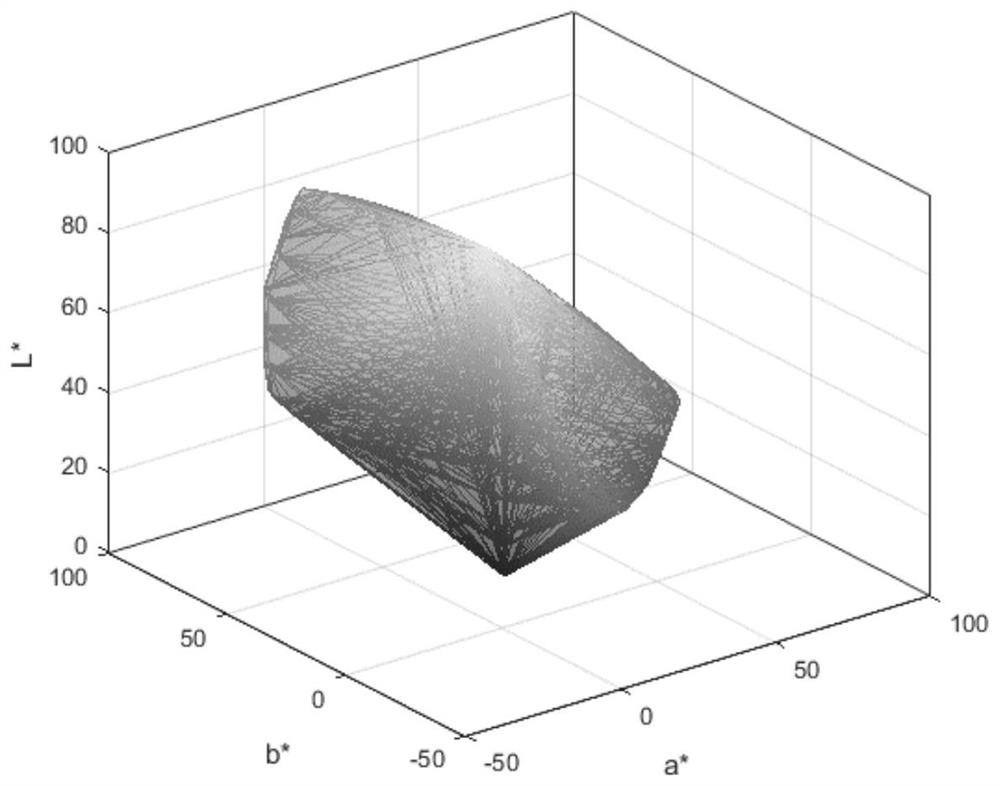

[0035] Such as figure 1 As shown, the embodiment provides a method for constructing the primary color system of colored spinning yarn, which can realize small inventory, scientific color matching, efficient development and digital management in the colored spinning industry. The embodiment adopts the most saturated color data of 98 hues and 15 neutral gray scale color data provided by a certain enterprise as the initial color gamut boundary color point data, and its color gamut boundary is as follows in CIELab color space image 3As shown, the enterprise's maximum primary color color difference threshold for producing plain colors is 10, and the method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com