Mechanical test system and method for dynamically controlling surface temperature rise of material

A technology of dynamic control and mechanical testing, which is applied in the field of testing machines, can solve the problems of not being able to reflect the temperature change of the sample well in real time, not being able to obtain test results, and lacking a test system and method with a controllable temperature rise rate, etc., to achieve Avoid the negative impact of the test, ensure the accuracy of the test, and optimize the effect of the test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

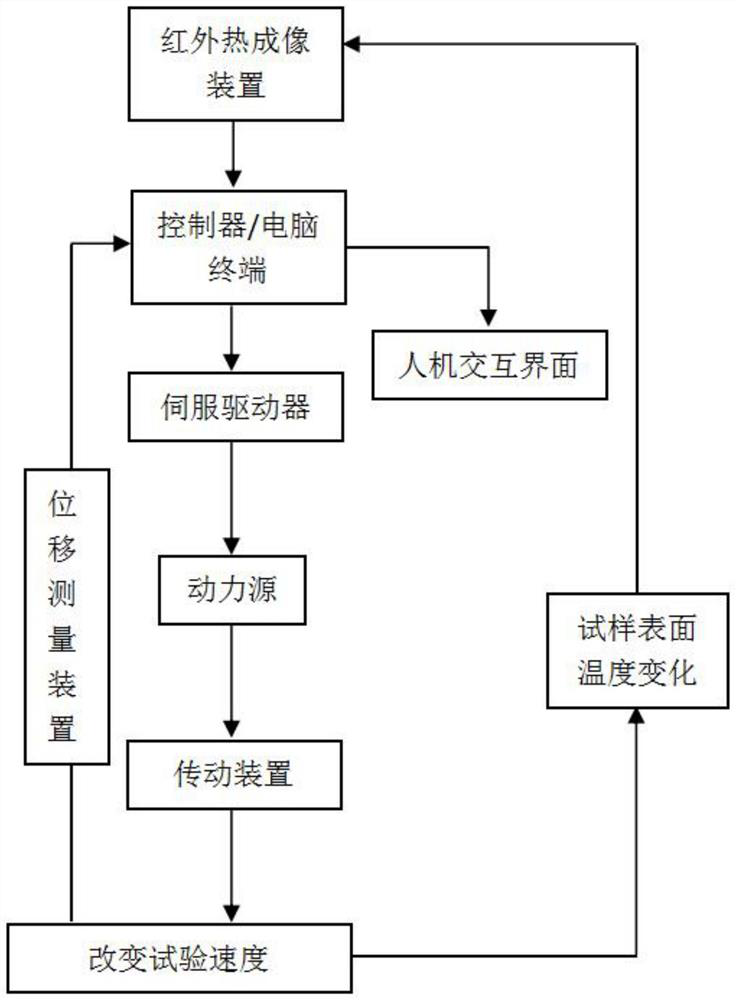

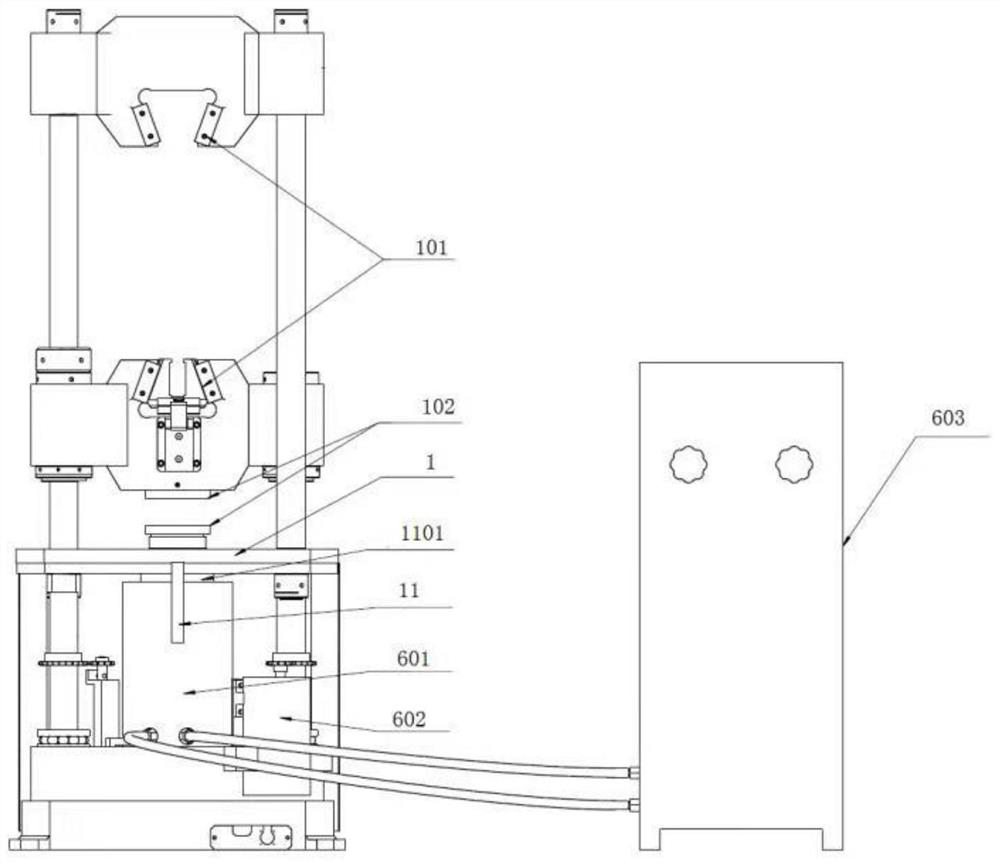

[0110] Such as figure 1 , figure 2 , image 3 As shown, a mechanical test system for dynamically controlling the temperature rise of the material surface includes a testing machine and an infrared thermal imaging sensor 3 for measuring the temperature of the material surface on a sample 8. The testing machine includes a power system, and also includes a controller, a clamping The fixture assembly of the sample, the crossbeam 5 connected with the movable fixture part 2, the controller is electrically connected with the infrared thermal imaging sensor 3 and receives the signal from the infrared thermal imaging sensor 3, and the controller is equipped with a real-time sensor according to the surface temperature rise of the sample 8. The controller is electrically connected to the power system and sends a control signal to the power system. Among them, the temperature control program can set the safe temperature of the sample surface during the whole test. The temperature does n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com