Rod type hydraulic linkage mechanism suitable for resisting progressive collapse of steel-concrete combined structure

A technology of combined structure and linkage mechanism, which is applied to building components, building structures, protective buildings/shelters, etc., can solve the problems of continuous structural collapse, failure to meet continuous collapse resistance, and failure to consider structural effects. The force transmission mechanism is clear, the continuous collapse is avoided, and the structure is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

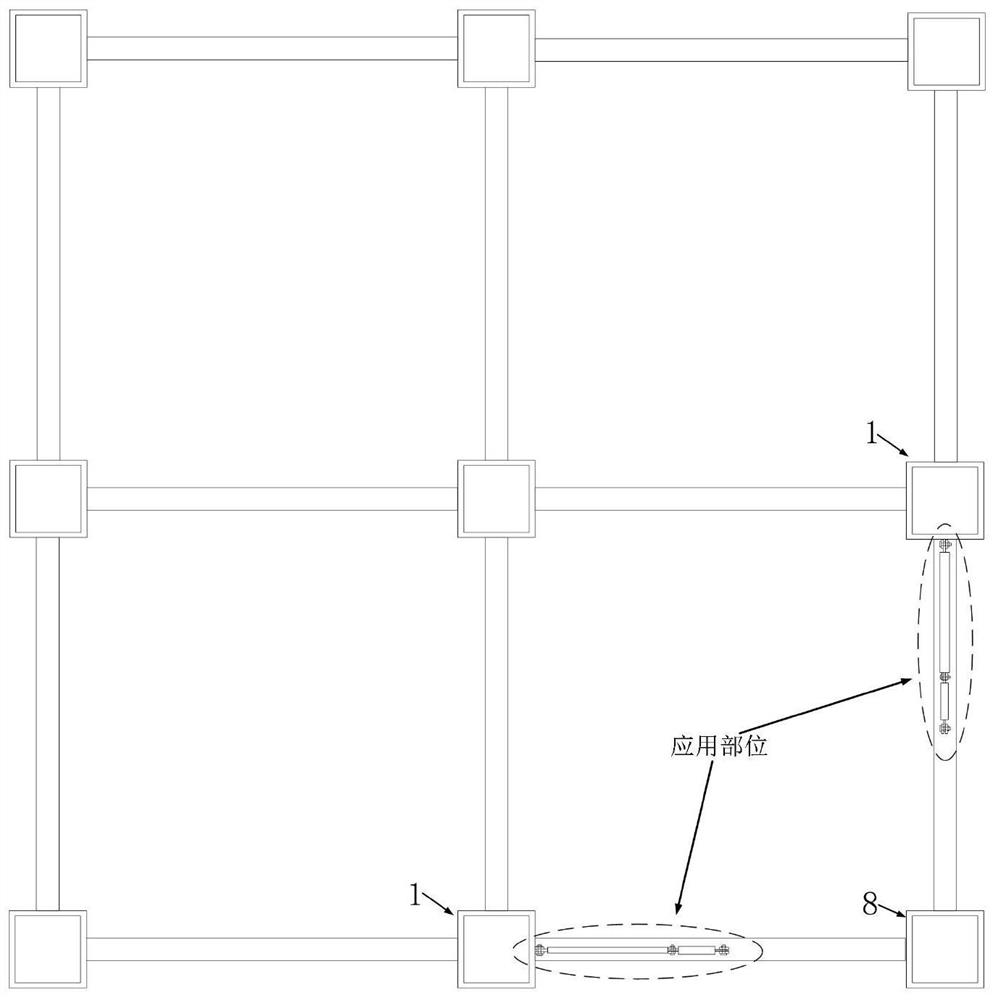

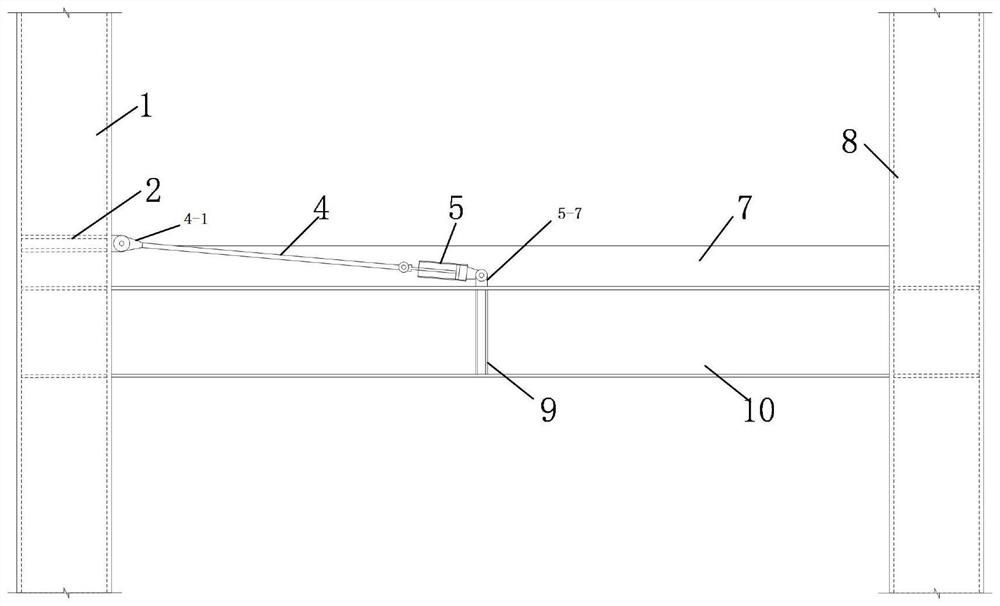

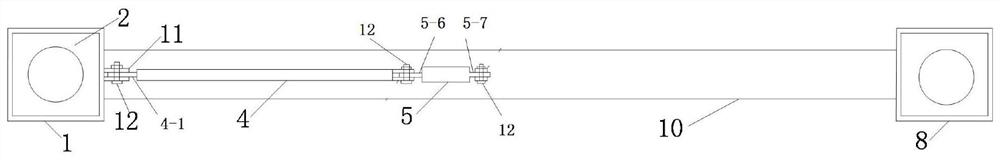

[0025] An anti-progressive collapse linkage mechanism suitable for steel-concrete composite structures, applied to the concrete-filled steel pipe column-steel beam scene, including convex corner columns (8), steel-filled concrete side columns (1), steel beams (10), and concrete floors ( 7), it is characterized in that: the rod-type hydraulic linkage mechanism includes a pull rod, an internal resistance hydraulic damper, several pin shafts, and several pin seats, wherein:

[0026] The tie rod (4) and the hydraulic damper (5) are connected in series through nodes, the damper is arranged flush with the axial center line of the tie rod, one end of which is connected to the column by a node, and the other end is connected to the steel beam (10) by a node, and the damping The full length of the device is buried in the concrete floor (7).

[0027] Further, each connection node is realized by a pin seat and a pin shaft mechanism. Further, the three nodes are arranged on the steel bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com