Crane running route planning method

A route planning, crane technology, applied in the directions of transportation and packaging, load hanging components, safety devices, etc., can solve problems such as the inability to ensure that the crane can safely bypass obstacles and affect the operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

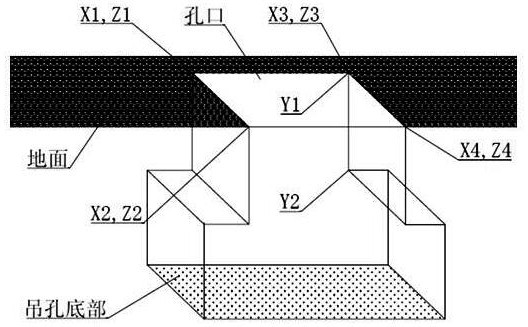

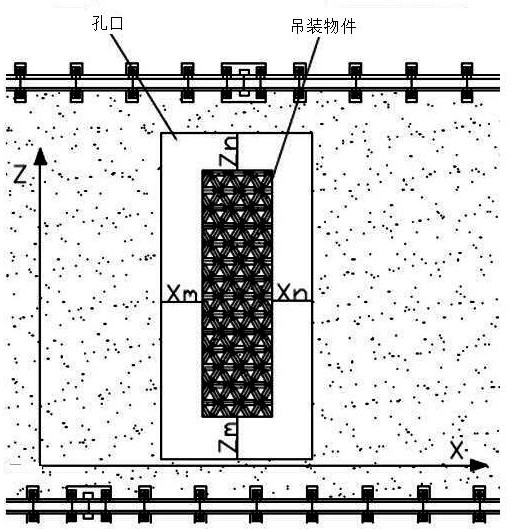

[0041] see figure 1 and figure 2 , a crane operation route planning method, comprising the following steps:

[0042] a. Use the three-dimensional coordinate model to define the operating position relationship of the crane in different directions, and use the lifting, cart and trolley position data to form a three-dimensional coordinate system;

[0043] b. Through the human-machine interface, set the passage space of the hoisting objects at each orifice in the PLC controller according to the three-dimensional coordinate system, and set the outer dimension of the largest pre-hoisted object in the PLC controller according to the three-dimensional coordinate system;

[0044] c. Write a PLC program to detect the lifting height value of the crane in real time during the operation of the crane, combined with the lifting height of the largest object set in the PLC controller, judge whether the lifting object of the crane is close to or lower than the orifice through formula 1 upper...

Embodiment 2

[0056] see figure 1 and figure 2 , a crane operation route planning method, comprising the following steps:

[0057] a. Use the three-dimensional coordinate model to define the operating position relationship of the crane in different directions, and use the lifting, cart and trolley position data to form a three-dimensional coordinate system;

[0058] b. Through the human-machine interface, set the passage space of the hoisting objects at each orifice in the PLC controller according to the three-dimensional coordinate system, and set the outer dimension of the largest pre-hoisted object in the PLC controller according to the three-dimensional coordinate system;

[0059] c. Write a PLC program to detect the lifting height value of the crane in real time during the operation of the crane, combined with the lifting height of the largest object set in the PLC controller, judge whether the lifting object of the crane is close to or lower than the orifice through formula 1 upper...

Embodiment 3

[0071] see figure 1 and figure 2 , a crane operation route planning method, comprising the following steps:

[0072] a. Use the three-dimensional coordinate model to define the operating position relationship of the crane in different directions, and use the lifting, cart and trolley position data to form a three-dimensional coordinate system;

[0073] b. Through the human-machine interface, set the passage space of the hoisting objects at each orifice in the PLC controller according to the three-dimensional coordinate system, and set the outer dimension of the largest pre-hoisted object in the PLC controller according to the three-dimensional coordinate system;

[0074] c. Write a PLC program to detect the lifting height value of the crane in real time during the operation of the crane, combined with the lifting height of the largest object set in the PLC controller, judge whether the lifting object of the crane is close to or lower than the orifice through formula 1 upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com