Automatic feeding device matched with four-column press

An automatic feeding, four-column press technology, applied in applications, household appliances, household components, etc., can solve the problems of low production efficiency and high labor costs, and achieve the effect of reducing labor costs, processing procedures, and equipment renovation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

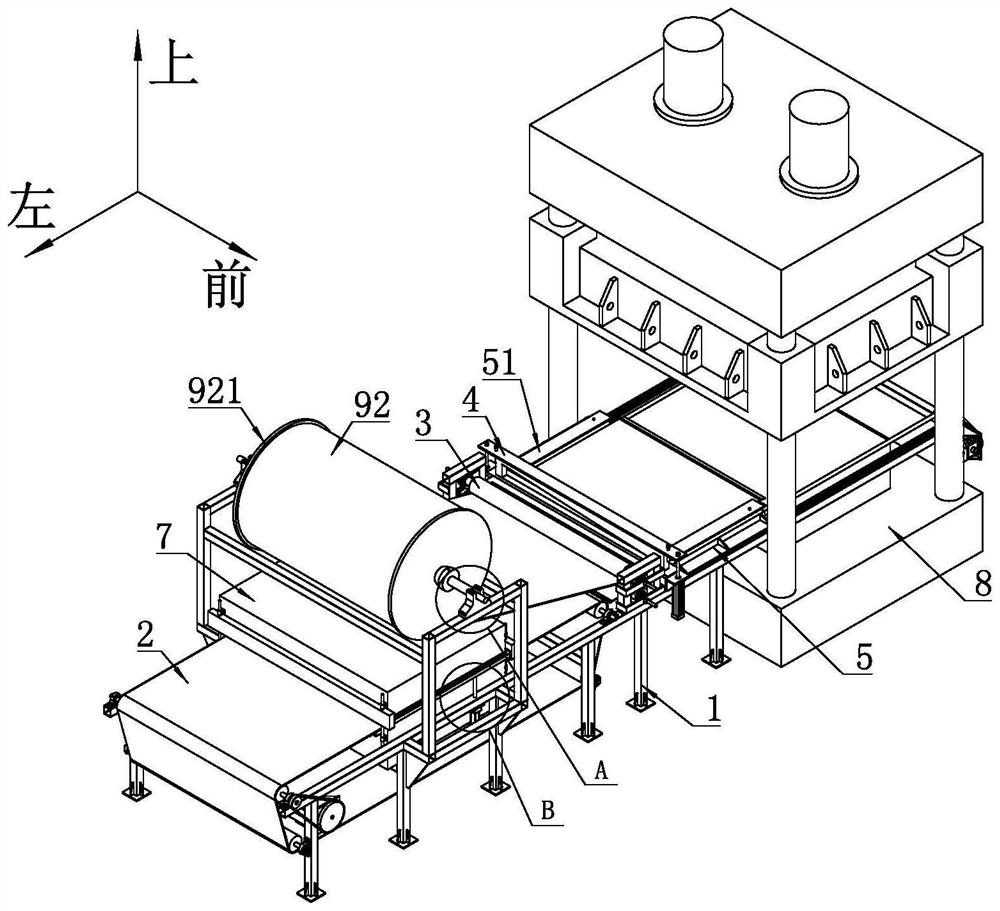

[0060] For the convenience of description, the coordinate system is defined as figure 1 , and the left-right direction is horizontal, the front-back direction is vertical, and the up-down direction is vertical.

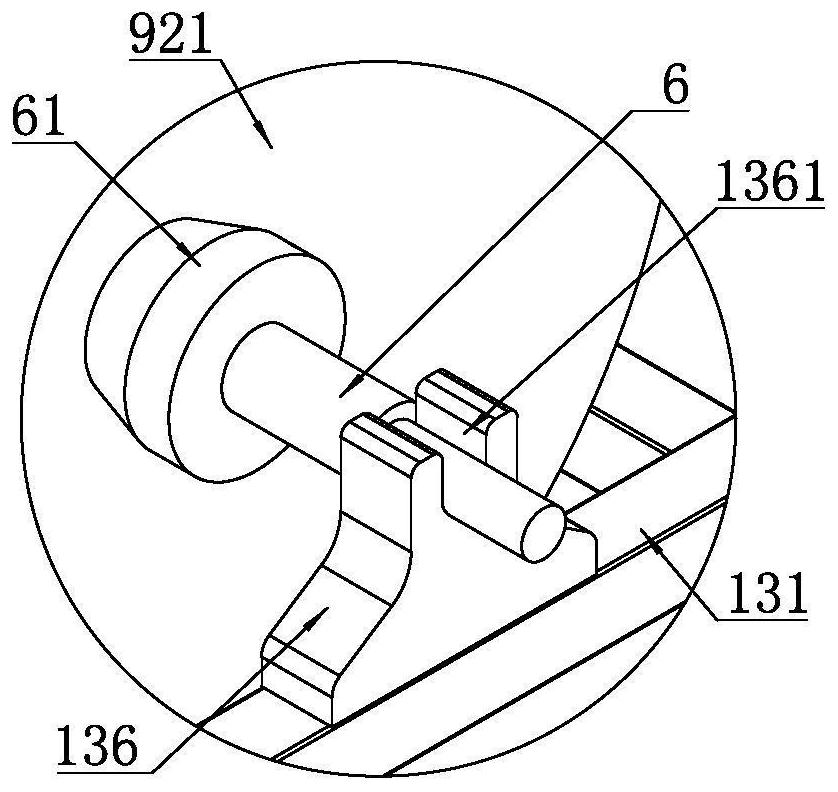

[0061] Such as figure 1 and Figure 4 As shown, an automatic feeding device matched with a four-column press includes a main frame body 1, and the main frame body 1 is provided with a conveying part 2, a pre-pressing part 3, a cutting part 4 and a Clamp the conveying part 2, the main frame body 1 is located above the conveyor belt 23 and is provided with a cross-arm shaft 6 for supporting the fabric roll 921, and the cross-arm shaft 6 is connected to the main frame Body 1 is rotatably connected.

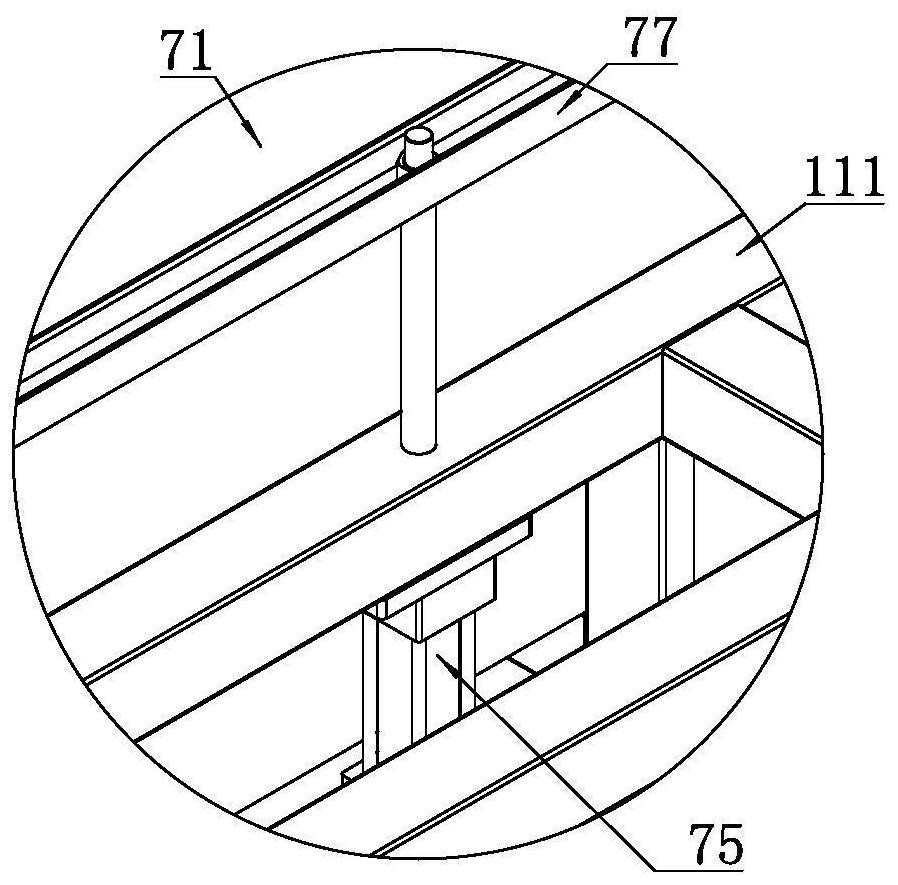

[0062] Such as figure 1 and Figure 7 As shown, the main frame body 1 includes two vertical frames with the same structure and arranged symmetrically. Describe the front and rear sides of the hot press 8 moulds. Below the crossbeam 111 are located on the left and righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com