Two-degree-of-freedom differential type mechanical arm joint module

A joint module and differential technology, which is applied in the field of medical robots, can solve problems such as low precision, inability to detect angles, and easy damage to the shaft, and achieve high precision, easy processing, and guaranteed coaxiality and verticality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

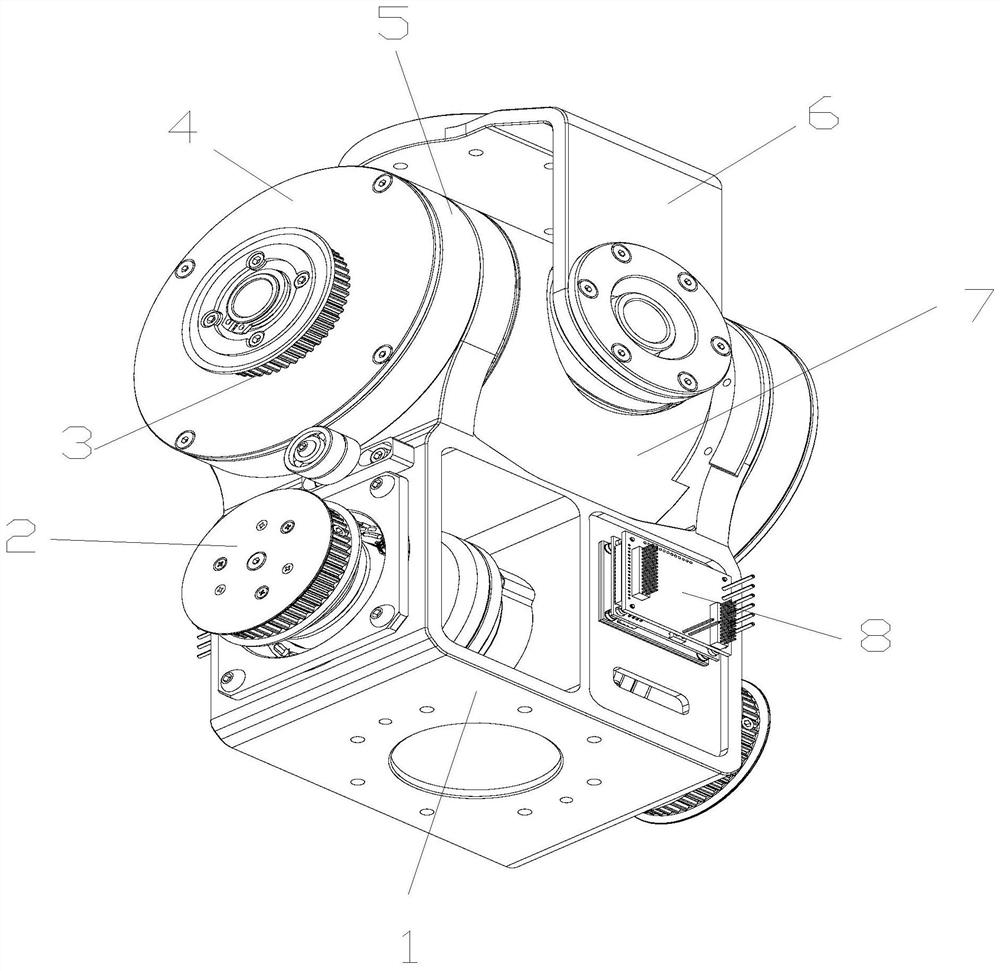

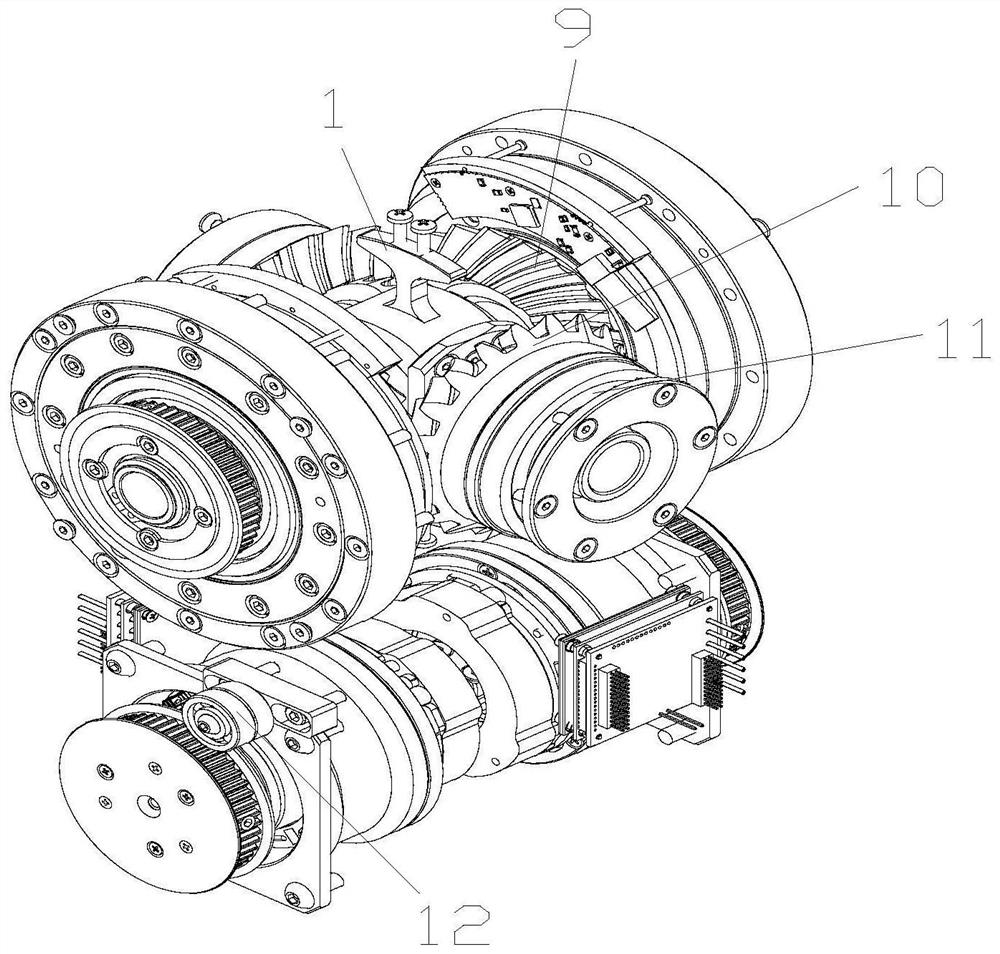

[0020] Such as figure 1 As shown, the two-degree-of-freedom differential manipulator joint module of the present invention mainly includes a bracket 1, a first power source, a second power source, two sets of belt transmission devices, two driving bevel gears 9, and two passive bevel gears 10 , cross shaft and output connecting rod 6.

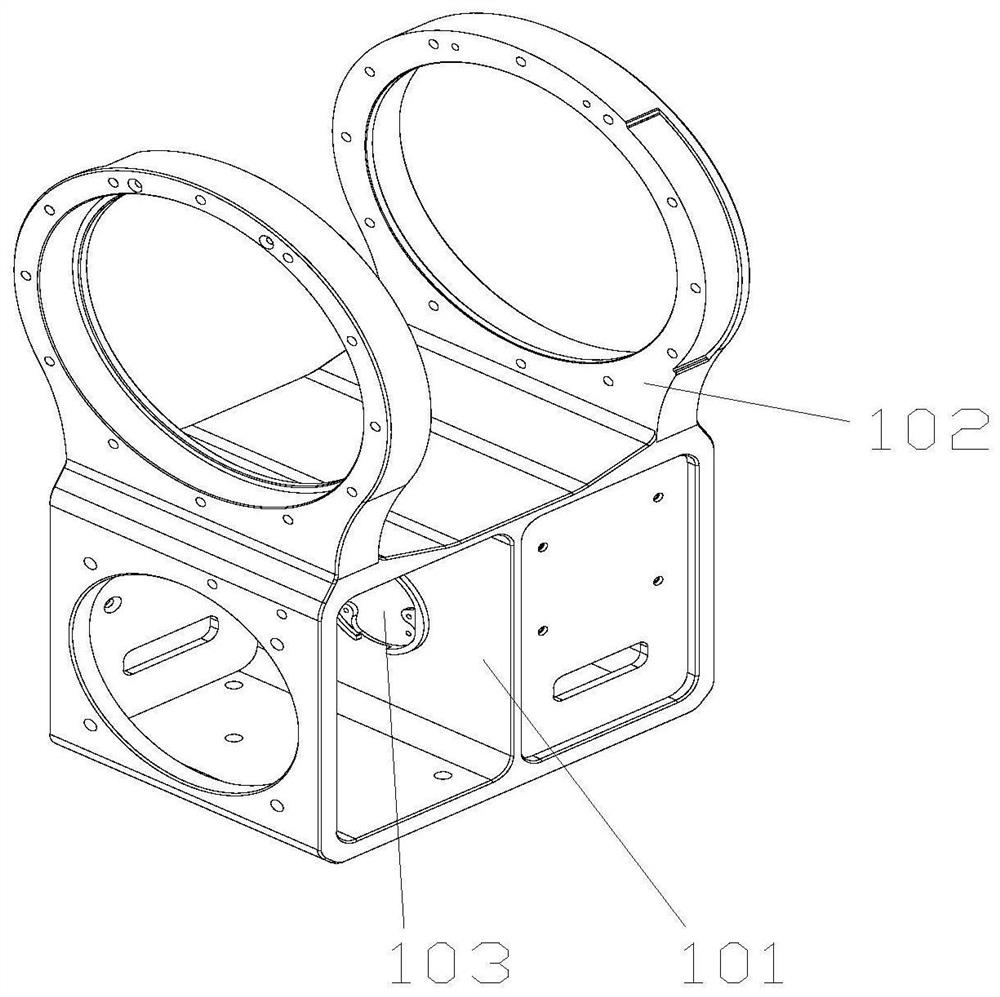

[0021] The first power source is exactly the same as the second power source, both driven by electric drives. The first power source and the second power source respectively include a motor, the motor is a frameless motor, the motor is covered with a motor housing 5, the motor housing 5 is fixed in the bracket 1, and the bottom of the motor is connected to the bracket 1 through a brake structure. The bracket 1 includes a body, which is provided with two cavities, the first power source and the second power source are respectively plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com