Extrusion mounting equipment for sealing washer of gas pipe connecting end

A technology for connecting terminals and sealing gaskets, which is applied to metal processing equipment, metal processing, hand-held tools, etc., and can solve problems such as waste of raw materials and terminal damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

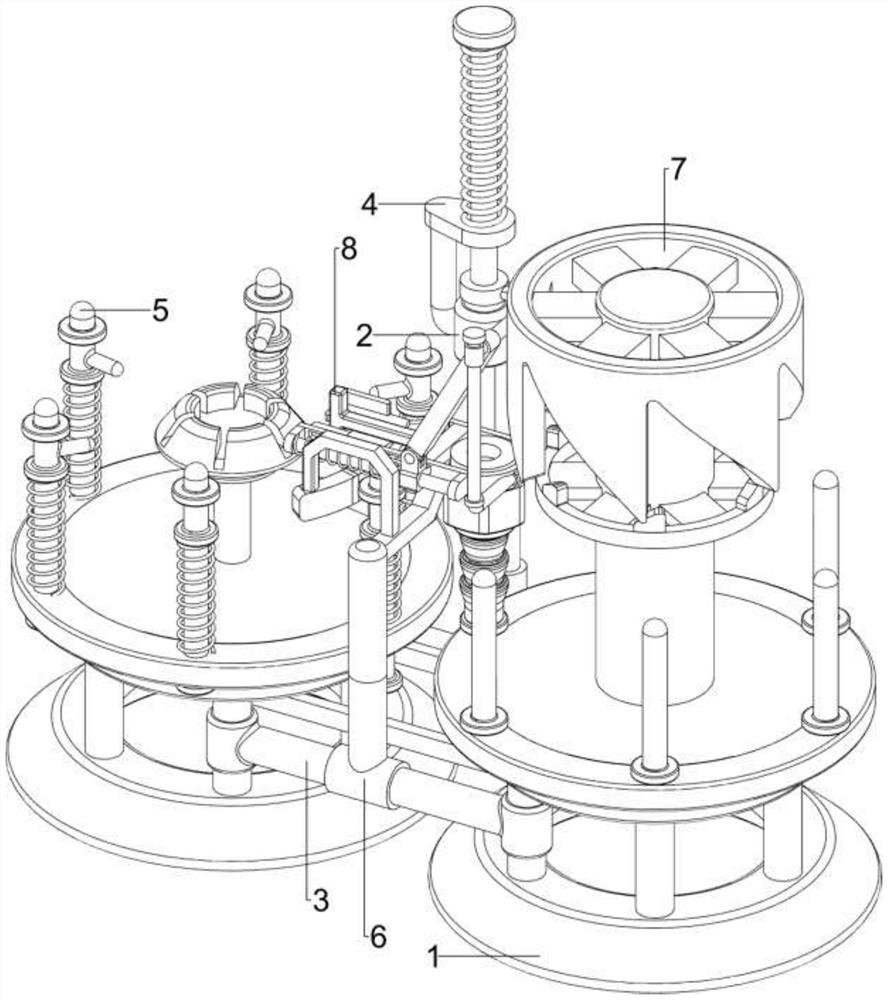

[0022] A device for extruding and installing the sealing gasket at the connection end of the gas pipe, see figure 1 As shown, it includes a base 1, a sleeve 2, a first discharging mechanism 3 and an extruding mechanism 4, the top of the base 1 is provided with a first discharging mechanism 3, and the parts of the first discharging mechanism 3 are provided with an extruding mechanism 4 , Sleeve 2 is arranged on 4 parts of extrusion mechanism.

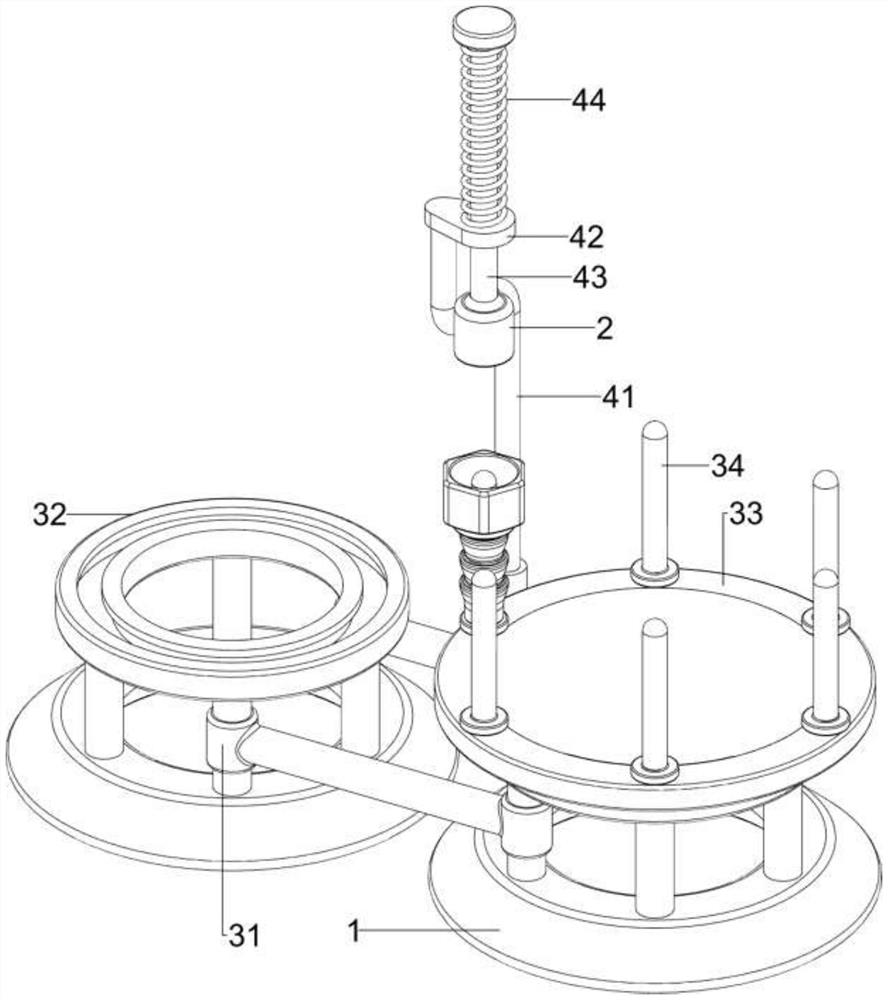

[0023] refer to figure 2 As shown, the first discharging mechanism 3 includes a limit frame 31, a slide rail 32, a first turntable 33 and a first placement rod 34, the middle part of the base 1 is symmetrically provided with a limit frame 31, and the top of the base 1 is symmetrically provided with a slide rail. 32. A first turntable 33 is slidably provided on the right slide rail 32, and six first placement rods 34 are uniformly arranged at the eccentric position on the top of the first turntable 33.

[0024] refer to figure 2 As s...

Embodiment 2

[0027] On the basis of embodiment 1, refer to image 3 As shown, a second discharge mechanism 5 is also included, and the second discharge mechanism 5 includes a second turntable 51, a second placement rod 52 and a retaining ring 53, and the left side slide rail 32 is slidably provided with a second turntable 51 , the eccentric position of the second turntable 51 is evenly slidable, and six second placement rods 52 are provided. Compression springs are connected between the second placement rods 52 and the second turntable 51, and retaining rings 53 are provided on the upper sides of the second placement rods 52. .

[0028] refer to image 3 As shown, a feeding mechanism 6 is also included, and the feeding mechanism 6 includes a second mounting frame 61, a material tray 62, a first clamping rod 63 and a limit plate 64, and the upper side of the second placing rod 52 is provided with a first The clamping rod 63 is provided with a second mounting frame 61 in the middle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com