Automatic efficient gluing equipment for electronic components

An electronic component and high-efficiency technology, used in coatings, devices that apply liquid to surfaces, etc., can solve problems such as the inability to achieve higher precision and accurate gluing operations, and the inconvenience of gluing heads close to the pin position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

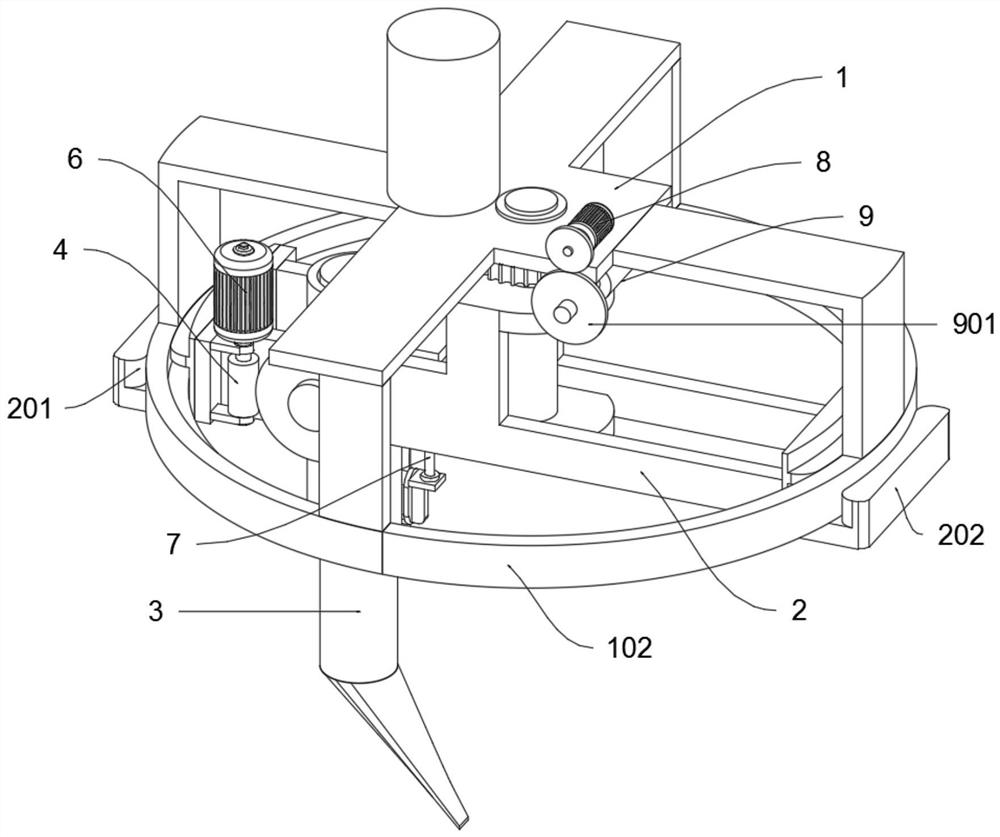

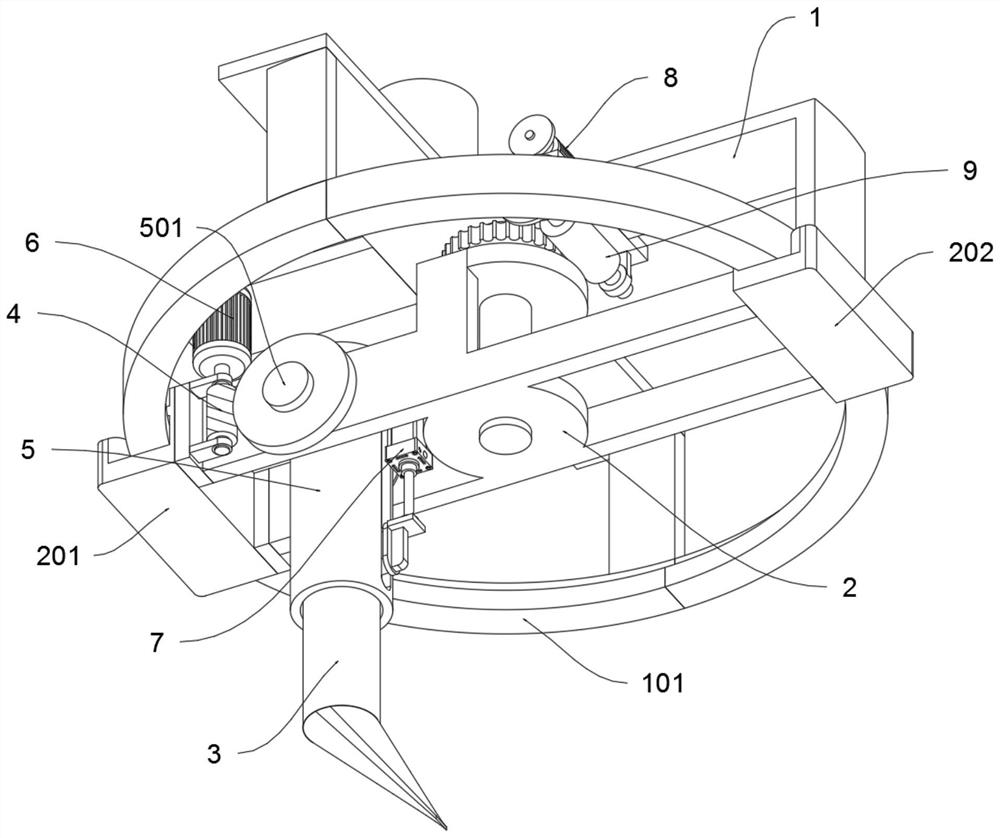

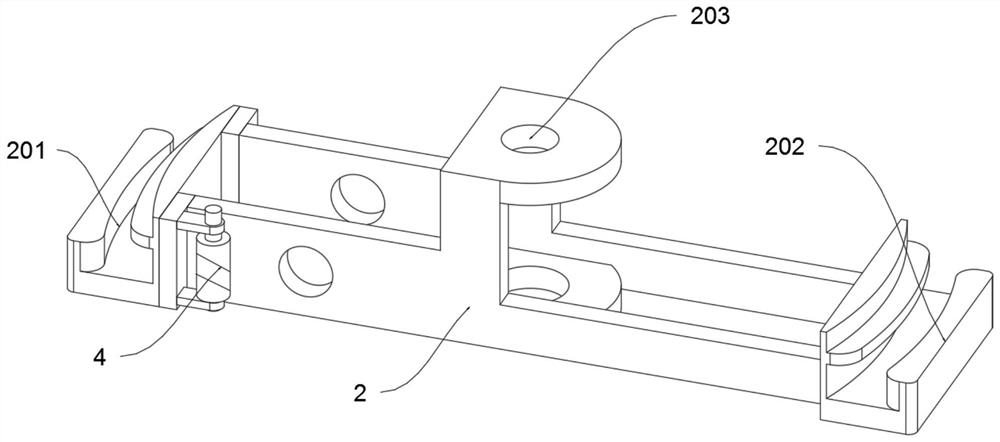

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034] The present invention provides a high-efficiency gluing equipment for automatic electronic components, including an upper connecting frame 1, a gluing head 3, a lower worm 4, a telescopic cylinder 5, a lower driving part 6, a telescopic driving part 7, an upper driving part 8, and an upper worm 9. The movable rotating rod 101 of the upper connecting frame 1 is fixedly connected in the middle fixing hole 203 of the rotating frame 2 through interference fit, and the two ends of the rotating frame 2 are slidably connected to the annular bracket 102 of the upper connecting frame 1; the lower worm The two ends of 4 are connected to the inner side of the rotating frame 2 through bearing rotation; the two sides of the upper end of the telescopic tube 5 are connected to the left side of the rotating frame 2 through bearing rotation, and the side worm wheel 5021 of the telescopic tube 5 is engaged with the lower worm 4; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com